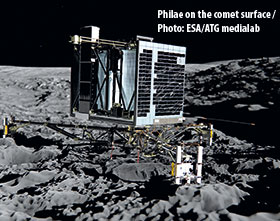

4:33 AM 14 June 2015. “Hello Earth! Can you hear me?” A lonely robot, freezing on an isolated space fragment, cheerily reaches out through Twittersphere to herald its reawakening. Seven months after being forced into an ultra low-power state of hibernation, the Rosetta Mission’s Philae lander has finally stirred from its slumber on the icy surface of Comet 67P/Churyumov-Gerasimenko, some 600 million kilometres away.

In November 2014, Philae had touched down to global applause as it became the first spacecraft ever to land on the nucleus of a comet. But, it had come to rest in the shadow of a crater. With its solar panels now unable to harvest the sunlight required to keep the batteries charged, the diminutive craft had been able to work only 60 hours before being obligated to 'go dark' in the primordial wilderness it had come to explore.

As luck would have it, Comet 67P’s elliptical orbit has now changed its position relative to the sun just enough for the rays to light up the solar panels of Philae’s outer shell. This is what breathed life back into the little comet chaser, including the 14 Faulhaber drive systems which defied the harsh conditions of the 10-year journey through the vacuum and low temperatures of space.

Because of the small size of the comet, about the size of Mt. Fuji in Japan, the force of gravity is very low in the region making it difficult to ensure a secure stance on the surface. Thus, the Max-Planck-Institut for Extraterrestrial Physics developed a special anchor system for the probe. Immediately after ground contact on landing, two harpoons were to be shot by a propellant charge into the surface of the comet to lodge into it. (Barbs were provided to prevent these anchor fittings from tearing themselves loose again.) As each harpoon shot out, it would have unwound a cable from a circular magazine. By means of a Faulhaber 1628 series brushless servomotor with a 16/7 planetary gearhead, this cable would then be wound back onto a drum until taut in order to secure the probe to the surface. At least that was the plan – unfortunately the harpoons were not fired, the rewinding mechanism was not used, and Philae ended up bouncing three times eventually coming to rest in a crater. Nevertheless, the miniature laboratory was still able to begin its analyses as planned.

Landing gear and sample analysis

During the landing phase, other motors had further important tasks to perform in order to transform the kinetic energy generated during the landing into electrical energy and finally into heat using a spindle drive. A Faulhaber 3557 series bell-type armature motor was connected directly through an external resistor and operated as a generator in this case.

Additional drives from the 1224 series were used in the three-legged landing gear of the craft in order to swivel or rotate the upper part by means of a cardan joint, so that the solar panels would always remain optimally aligned. Microdrives were also needed for taking samples: the lander has a drill that feeds core samples into an oven for pyrolysis. Small 1016 series motors with 10/1 planetary gearhead drive a cam via a worm arrangement. This provides feed to a ceramic breech piece on the oven and simultaneously closes the electrical contacts for the oven heating element. The combustion gases generated in the furnace are then routed through tubes in the oven latch to the scientific instruments for analysis. During its first scientific phase, which lasted a total of 60 hours, the lander performed all of the planned scientific measurements on the comet surface. Philae successfully transmitted this data to the Lander Control Centre before it went into hibernation. Now that the orbit has shifted and its upper part is better aligned with the sun, Philae has revived itself and is once again ready to perform the galactic research for which it was designed. The European Space Agency regards the mission as a complete success, but evaluation of all the received data will take some time.

Outer space and its demands

The demands that outer space place on these drives are high: every kilo of mass that is shot into space costs energy, i.e. fuel – hence money too. Therefore, small, light solutions are sought. At the same time, however, they must also be able to withstand the enormous vibration and acceleration forces during take-off, as well as the constant very-low temperatures and the many years of vacuum conditions prevailing in outer space.

Because cost also plays a major role when selecting components for space projects, the developers wanted to do without costly custom developments if at all possible. Accordingly, they first looked for standard products which complied with as many of their specifications as possible. They found what they were looking for in the comprehensive drive systems product range from Faulhaber. The standard drive solutions fulfilled all mechanical requirements, and the special conditions in space could then be met by making comparably few modifications at negligible additional cost.

For more information contact David Horne, Horne Technologies, +27 (0)76 563 2084, david@hornet.cc, www.hornet.cc

| Tel: | +27 76 563 2084 |

| Email: | info@hornet.cc |

| www: | www.hornet.cc |

| Articles: | More information and articles about Horne Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved