The industrial automation industry could be poised for a re-ordering of market share based on the advent of the concept of `integrated architecture'. Historically, players in discrete, hybrid/batch, and continuous process control competed with different technologies, with little to no integration across control disciplines. The integrated architecture of Rockwell Automation's Logix operating system is a fundamentally new 'game changing' technology that is unique among the major control industry competitors and will enable Rockwell to take significant market share as the industry moves to integrated solutions.

This was the central message in the newly released Lehman Report, produced by the global equity research experts for resource evaluation. "With Logix, we think Rockwell has established a technological lead that could take competitors years to replicate," states the report. "Logix represents a fundamentally new integrated architecture that enables integration horizontally across control disciplines, as well as vertically into the information domain. In our view, the key differentiating feature of Logix, is its capability to seamlessly transition across control disciplines with a single view to the user."

In the 1970s when Rockwell invented the programmable logic controller (PLC), machine control was a box of switches called relays that were set in an order (the relay ladder logic) that defined the machine's operation. This was a clumsy process. There was a need for a better way, and that way turned out to be PLCs. But this was still not fast, flexible or easy enough to use. What Rockwell Automation has now come up with is the Logix operating system, capable of interpreting and executing all four IEC-1131 standard languages and able to transition seamlessly across disciplines. None of Rockwell's competitors are close to achieving this, according to the Lehman report.

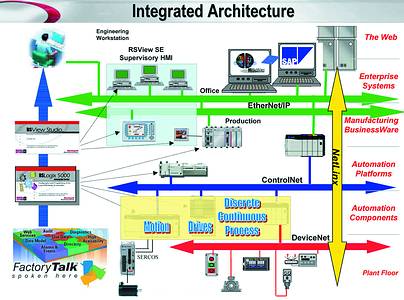

"To provide true integration across the entire automation spectrum, it should be possible to configure and program automation devices and network from one central engineering station" explains Rockwell Automation, automation components manager, Clive Barwise. "We have spent billions of dollars in arriving at such an integrated control system architecture, composed of hardware and software products, including ViewAnywhere at the top level, ControlLogix at the PLC level, and ControlNet as communication network. These, plus the ability to interface to DeviceNet and Foundation Fieldbus interfaces, form a complete control solution for both the discrete and process segments of process applications."

Since all segments of process application can now be controlled using a common control architecture, supplied by a single manufacturer, users can reduce spares inventories, and conduct fewer operator and maintenance training courses. In addition, the modular nature of Rockwell Automation's integrated architecture also permits users to automate applications incrementally, starting small and easily expanding to meet future requirements. The integrated architecture has true interoperability with legacy Allen Bradley PLC, and even Allen Bradley PLCs that are decades old can be integrated with ease.

Both DCS and PLC controllers are supported by the Integrated Architecture. ProcessLogix is fully integrated with a system server, network, and I/O modules to provide a full suite of DCS services, including global database services, advanced engineering tools, plus alarming, trending and archiving functions. The ControlLogix, CompactLogix and FlexLogix controller supports a variety of control requirements, including basic PLC functions, and motion and drives control.

"The introduction of personal computers, and Management Information Systems thereafter, created the concept of viewing or controlling a host of related functions through one central screen, with a uniform look-and-feel and uniform functionality. It took decades for this ease-of-use to be achieved in industrial automation, and even though that is just one of the many advantages that the concept of integrated architecture holds, I am sure that it will shape the future as far as the evolution of industrial software is concerned," Barwise concludes.

For more information contact Jeff Sandison, marketing communications manager, Rockwell Automation, 011 654 9700, [email protected], www.ra.rockwell.com

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved