Operating safely

September 2009

Fieldbus & Industrial Networking

Fibre-optic fieldbus systems in oil production.

Hirschmann networks recently developed oilfields in the United Arab Emirates with highly available fibre-optic fieldbuses.

Production has recently started at two new oilfields 50 km southwest of Abu Dhabi city, Rumaitha in the countries interior and Al Dabb’iya on the coast. The daily production capacity of the fields is about 100 000 barrels. The facilities for producing, storing and metering the crude oil have been in operation since late 2005. Operating safety is paramount here, so the process control system has been designed with full redundancy, and data is transmitted between the controllers and the remote I/O stations via fail-safe, redundant optical fibres. The danger of explosion that is inherent in such facilities presents a particular challenge. This challenge must be met with ATEX approved devices that are also capable of withstanding high ambient temperatures.

Project details

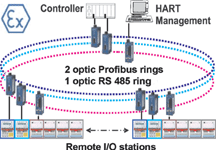

The process control is designed as a redundant system to specifically meet the customer’s demand for high process data availability. The process control units constructed by Honeywell provide a primary and a secondary Profibus DP interface with the remote I/O stations. HART information is recorded via an independent service bus using an RS485 interface. Optical cables and redundant optical rings ensure an exceptionally high level of operating safety. The cabinets, installed in explosion protection zone 2, include devices for properly isolating the intrinsically safe signals that are primarily used here for transmitting to zone 1 and zone 0. The power supplies for the remote I/O stations are designed redundantly. The cabinets have been engineered to prevent heat accumulation and they are also equipped with solar protection means. Otherwise, it would not be possible to keep the electronic components in the cabinet sufficiently cool in desert conditions.

Project parameters

* Profibus DP and HART communication.

* 15 km transmission length.

* 2600 process signals.

* 72 remote I/O stations.

* 176 OZD Profi 12M G12.

* 26 OZD Profi 12M G12-1300.

* 88 OZD 485 G12.

* 13 OZD 485 G12-1300.

Requirements

* High availability of the process control system.

* 85°C solar temperature.

* 52°C air temperature.

* 95% maximum air humidity.

* Explosion protection zones 2 and 1.

Solution

* Redundant control stations with two Profibus interfaces.

* Redundant communication via optical Profibus DP rings.

* Communication with HART management system.

* Switch cabinet designed for high operating temperature.

* Devices ATEX-approved.

Why Hirschmann

* Fibre-optic converter for Profibus DP.

* Fibre-optic converter for HART via RS485.

* Designs for long and medium segments.

* Redundancy with optical rings.

* ATEX approvals received.

For more information contact Profitek, +27 (0)12 664 4998, [email protected], www.profiteksa.com

Further reading:

Comprehensive solutions for the food and beverage sector

RS South Africa

Fieldbus & Industrial Networking

RS South Africa is reinforcing its commitment to the country’s dynamic food and beverage sector, backed by a comprehensive portfolio of over 800 000 products, extensive technical expertise and end-to-end service capabilities.

Read more...

Case History 198: Cascade control overcomes valve problems

Michael Brown Control Engineering

Fieldbus & Industrial Networking

A large petrochemical refinery asked me to perform an audit on several critical base layer control loops. This article deals with a problem found on a valve controlling the flow of fuel to a heat exchanger.

Read more...

Improved networking technology for fire and gas detection

Omniflex Remote Monitoring Specialists

Fieldbus & Industrial Networking

Critical alarm and event management technology supplier, Omniflex has worked with the South African Nuclear Energy Corporation to upgrade equipment providing digital and analogue signals for its safety critical fire and gas alarm systems.

Read more...

PC-based control for fertiliser

Beckhoff Automation

Editor's Choice Fieldbus & Industrial Networking

On a farm in the USA, valuable ammonia is extracted from slurry and processed into ammonium sulphate. NSI Byosis has transformed this complex process into a flexible modular system. This modular approach requires an automation solution with flexible scalability in both hardware and software, which this Dutch company has found in PC-based control from Beckhoff.

Read more...

Loop signature 28: Things to consider when tuning.

Michael Brown Control Engineering

Editor's Choice Fieldbus & Industrial Networking

I was giving a course at a remote mine in the middle of the Namibian desert. We were discussing tuning responses, and as I always do on my courses, I mentioned that in my opinion ¼ amplitude damped tuning is not desirable, and is in fact not good.

Read more...

How industrial network design impacts ESG commitments

Omniflex Remote Monitoring Specialists

Fieldbus & Industrial Networking

In safety-critical industries like nuclear, petrochemical and oil and gas, installing a new industrial cable network is an extremely complicated task. Gary Bradshaw, a director of industrial network specialist, Omniflex explains why this is often unnecessary as plants are likely to have existing cabling capable of being used to create new industrial networks.

Read more...

Minelert industrial solutions

Fieldbus & Industrial Networking

Profitek provides cutting-edge industrial networking, automation and IoT solutions for harsh environments.

Read more...

The ultimate industrial LoRaWAN gateway

Fieldbus & Industrial Networking

The GW-101-LORA-4AO is the ultimate industrial LoRaWAN gateway, combining advanced IoT connectivity with expandable I/O.

Read more...

Industrial Power-over-Ethernet DC injector

Fieldbus & Industrial Networking

The ML-NET-INJECT series sets the standard for industrial PoE, featuring IP68-rated RJ45 connectors and military-grade components for extreme reliability.

Read more...

Industrial networking IO-Link

Fieldbus & Industrial Networking

Balluff IO-Link Network Modules enable seamless, intelligent communication between sensors, actuators and control systems. Designed for Industry 4.0, they provide real-time data exchange, simplify wiring, and enhance diagnostics.

Read more...