The supply of primary foodstuffs such as dairy products is subject to increasingly close scrutiny. To stay in business profitably in the dairy industry requires the consistent provision of quality products and unswerving compliance with ISO standards. Humansdorp’s Woodlands Dairy is well up to the challenge.

Background

Woodlands Dairy previously bought a second hand powder plant from Denmark but the control system was outdated and not suitable for the modifications required to adapt the process to Woodlands’ specifications. This started a chain of events that would not only require a production monitoring and control system for the powder plant but also prompt the company to consider how this expansion could be integrated with the rest of the site.

“This made us take a step back and consider what we really needed for the company as a whole,” says Jan Barnard, process engineer, Woodlands Dairy. “Up until now, all we had on site were OEM installations and an old InTouch system but no PLC or scada standards.”

Project requirements

Top of the agenda was a single platform that could integrate all the disparate plants onsite while preserving past investments in expensive assets and legacy systems while making provision for future expansion.

“We also needed a centralised environment for process data-logging which would allow us to analyse data in real-time and produce reports,” says Barnard. “Another requirement was flexible security facilities that would allow operator access only to designated areas of the plant. Finally, we needed system redundancy to provide for uninterrupted operation as well as the ability to develop and deploy solutions from a central point for ease of maintenance.”

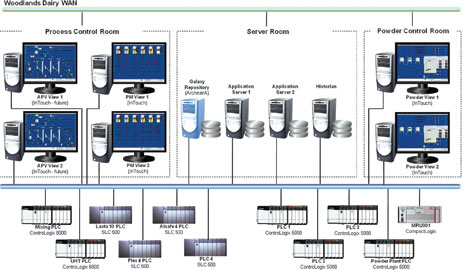

The best solution to handle these diverse requirements was Wonderware’s System Platform consisting of the Aplication Server, InTouch (HMI/SCADA), Historian and ActiveFactory trending and reporting tool.

“We chose Wonderware for a number of reasons,” says Barnard, “not the least of which was my previous experience with their products.”

Other reasons included:

* Universal data connectivity which could cope with Woodlands Dairy’s variety of PLCs.

* Object orientated technology which was more maintainable than its alternative and also promoted standardisation.

* A distributed system.

* Easy to create reports and easy retrieval of historical data.

* Full redundancy.

* Scalability.

* A high level of support in South Africa.

Implementation

The total implementation took about six months, half of which was spent on the new powder plant which was commissioned first. While the powder plant was a greenfields project, the processing plant upgrade and expansion was done live during weekly shutdowns and the standards developed for the powder plant were rolled out for these projects.

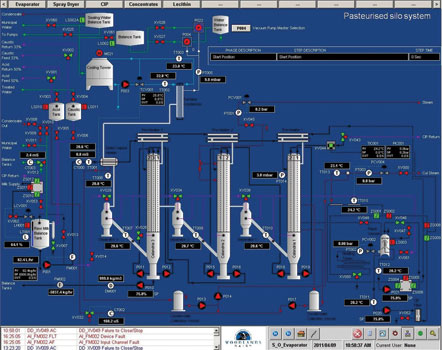

Other process areas were also upgraded. These included a new clean in place (CIP) station, a new cream pasteuriser/butter plant, an upgrade to the milk pasteuriser, new pasteurised milk silo and milk lines, a new pasteurised cream silo and a new milk reception area with its own CIP station.

Standards design

“Starting from scratch, we used the System Platform checklist as a guideline for our standards design,” says Barnard. “This helped us progress to our naming convention and plant model design as well scada standards such as navigation, graphics and control modules. We used ArchestrA standard templates throughout which would help later with maintenance and reduced engineering costs. We also implemented PLC standards with regard to the ControLogix and SLC500 PLCs.”

According to Barnard, Woodlands is now looking at making information such as KPIs more visible and widespread using Wonderware’s information server, while the performance module will prove useful on the sterilisers and pasteurisers as well as the standalone TetraPak filler line.

Benefits

Woodlands Dairy’s expansion resulted in a number of benefits:

* Reduced engineering cost – this is a direct result of rolling out the standards that were defined at the start of the project.

* Compliance with ISO 22000 – this is an important achievement with regard to local and international recognition as applicable to food safety (since food safety hazards can occur at any stage in the food chain it is essential that adequate control be in place).

* Improved quality control – the silo milk release system is interlocked with the laboratory InTouch system and CIP reports, which means that only product that meets the company’s specifications and ISO requirements is released.

* Operator confidence – now that they have visibility into the entire plant, operators are increasingly confident about the status of processes and their effect on them.

* Improved troubleshooting capabilities – accurate historical data results in equally accurate cause and effect scenarios for diagnostic purposes. * Accurate reporting – this includes real-time reports on production performance and milk loss.

* Standards in place for future use – system integrators who may have to work on the system in future have documented reference regarding the company’s standards and requirements. This improves understanding and helps ensure that everyone is on the same page.

For more information contact Jaco Markwat, Invensys Wonderware, +27 (0)11 607 8100, tech@invensys.co.za, www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved