Lonmin’s Marikana complex is one of the largest and most significant platinum mining and processing operations in the world. Located near Rustenburg in the North-West province, the complex consists of 14 shafts, seven concentrators, a smelter and a base metals refinery.

The Marikana operation uses five ArchestrA Galaxy Repository (GR) servers, 43 ArchestrA Object Servers (AOS), 42 view stations and 14 Wonderware Historian servers. Of this, the Concentrator Galaxy consists of 16 AOS, 16 view stations and nine Integrated Development Environment (IDE) stations monitoring nearly a quarter million tags across 68 PLCs. The rest of the system is used for the shafts, services, smelter and metal accounting.

“This project involved the upgrade of Wonderware’s System Platform 3.0 to release 3.1 on all the concentrators,” says Lonmin automation specialist, Johan Louw, “While upgrades are normally routine affairs, this one bears mention because each of the concentrators involved operates individually and has its own shutdown schedule making it impossible to arrange for a full concentrator shutdown. The upgrade would have to be done live during full production and with no downtime.”

Concentrator architecture

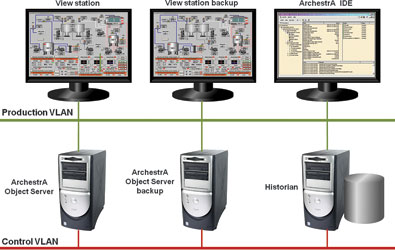

Lonmin has defined an operating environment for its concentrators which, for security purposes, has a DMZ to isolate the control VLAN (PLC connection) from the production VLAN (viewing, development, etc). (Figure 1.) The Historian is also standardised for each concentrator. A viewing station and its backup are included as well as an ArchestrA IDE station. This makes each concentrator a self-contained production unit with a standardised architecture but individual control.

Challenges

* Implement upgrade with no plant downtime – production stoppages could not be tolerated, yet any upgrade normally requires installing new software and restarting the system. A work-around had to be found.

* Operators to have visibility into the plant at all times – once again, this precluded any system downtime.

* Improve system performance – the magnitude of the concentrator complex demands highly optimised approaches if system performance is to be improved.

* Get buy-in from users – it is not unusual for system changes to be viewed with some degree of scepticism and the success of the project depended on users taking ownership of the new solutions.

How it was done

“Fortunately the sites were designed to run two AOS servers (one backup – see Figure 1) and this architecture supported what we wanted to do,” explains Louw. “With the help of Wonderware Southern Africa, we introduced an additional upgraded Galaxy Repository (GR) Server to form a parallel galaxy. We then upgraded the backup AOS servers. This could still be done with no downtime. The next step was to upgrade the view station and the IDE, so that two view stations were running the same applications on two parallel galaxies. Once each IDE was upgraded, users could start doing development on the new galaxy. Any new development on the old galaxy would at this stage be lost. The next step was to change over the Historian and finally the old AOS. After all the sites were done, the old GR was decommissioned and prepared for the next upgrade. The result was a major system upgrade with no downtime and no loss of visibility into the plant.”

Since the rollout was not done on a full-time basis and was interlaced within normal day-to-day activities, it took about three months. “This also gave us time to implement best practices and to validate our existing GRs,” says Louw. “What impressed us most is that, with ArchestrA, engineering and configuration time is sliced in half. Another notable feature is the ability to manage the software from a central point, as well as enforcing standards across the business.”

According to Louw, the most impressive aspects of the system architecture include:

* Scalability. “We were able to do load sharing on areas where a lot of processing power was required.”

* The ability to enable redundancy in critical areas.

* Distributed architecture which simplifies the process of backups and reduces downtime in the event of hardware failure.

Benefits

* Major system upgrade with no downtime and no loss of visibility into the plant.

* Improved system performance.

* Development of a risk-free method for implementing future upgrades.

* Improved user confidence in the capabilities of the system and its upgradeability.

Conclusion

A seamless upgrade of this magnitude goes to show what can be done with modern technology and ingenuity. Systems are there to help monitor, control and improve production - not to stop it dead in its tracks for a routine software upgrade. Marikana’s six historians log 350 million readings a day in the concentrator galaxy alone and to have this continue in real-time during a plant-wide system upgrade with nobody noticing and without missing a beat is impressive. It is a great example of inventiveness merging with technology.

For more information contact Jaco Markwat, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved