Thus, APACS+ is an OPC-compliant system that enjoys bi-directional communication with other OPC-compliant equipment which minimises the limitations imposed by proprietary systems.

The APACS+ OPC server provides:

* Plantwide visibility and a common process history by storing and organising data from other servers in the system.

* Advanced alarm-handling via standard functionality that distributes individual alarms to all clients subscribing to it and automatically directs alarm acknowledgements back to the device that initiated it.

* Bumpless client switch-over between servers in a server set.

Providing complete plant data

As a full-function OPC server to any OPC client, as well as a concentrator for third-party OPC servers, the APACS+ OPC server enables any OPC server to communicate with any client assigned to it - regardless of the communication protocol used by the client. This allows APACS+ to distribute realtime data, system alarms and system events to other automation systems.

The APACS+ OPC server also enables any OPC client to communicate with any server assigned to it - regardless of the communication protocol used by the server. As such, APACS+ supports OPC client capabilities, allowing it to display data and alarms from third-party OPC servers. The APACS+ OPC server also centralises and organises the information it receives from other servers in the system, thereby providing plantwide visibility (via ProcessSuite Vision) and a common process history (via ProcessSuite Historian).

The APACS+ OPC server includes:

* The Core Server, which is both an OPC server and an OPC client, and has a data item address space, an alarm and event address space, built-in server redundancy, and process alarm-handling.

* The Tag Locator, which provides the ability to browse tags in the core server.

* Device servers, which request data from devices that use a communications protocol other than OPC.

* Client adapters, which communicate with clients that use a protocol other than OPC.

Organising information

The server's Data Item Address Space organises and stores data read from any data server assigned to it in the network. Information is organised in a tree-like structure that matches the path to a data value for easier tag management.

Each data item (branch or leaf) in the address space can be assigned a shortcut name, enabling you to compensate for any tagname length restrictions.

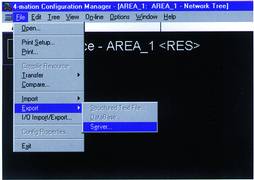

External programs are used to configure the data item address space. If, for example, the client were an APACS+ advanced controller, the ProcessSuite 4-mation configuration software would be used to configure the data item address.

Monitoring and recording system events

The server's alarm and even address space includes a category hierarchy and event hierarchy as specified by the OPC standard. The category hierarchy enables the user to organise system event conditions, while the event hierarchy allows them to define the specific event sources to be monitored in the system. Event sources, which can be grouped into areas, are tied back to a data item in the data item address space and a condition in the category hierarchy. An event area can contain individual event sources, as well as other event areas.

Tools are provided to assign event areas and event sources to each client of the OPC server.

Delivering improved alarm handling

The product provides an alarm-handling technique that distributes individual alarms to all clients that subscribe to it and provides a mechanism for automatic acknowledgement back to the device that initiated the alarm. This acknowledgement scheme, which is standard within the APACS+ OPC server and transparent to the user, is available without the need for scripts.

Providing increased availability

Built-in server redundancy is provided via server sets. Each server set can contain two APACS+ OPC servers, with one acting as the primary and the other as back-up.

Each client to a server set periodically verifies the health of each server in a server set. If the back-up server(s) is healthier than the primary, the client will automatically switch over to the back-up.

Mechanisms are provided to maintain synchronisation between servers in a server set. This synchronisation governs process information as well as configuration information in each server of a server set.

| Tel: | +27 11 466 1673/9 |

| Email: | info@moore.co.za |

| www: | www.moore.co.za |

| Articles: | More information and articles about Moore Process Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved