Effective solutions that minimise consumption during peak demand times will save companies money and assist Eskom as it works to build its capacity.

Initiated, managed and commissioned by HVAC International, under the Eskom DSM programme, this project manages the electrical supply by ensuring successful load shift from peak to off-peak times – whilst Eskom addresses the longer term energy needs of the country.

It makes sense for Eskom to fund projects like these, as it helps work towards the position where capacity can meet power demand during the peak periods. Another objective of this project was to optimise the pumping process ensuring minimal influence of end-users’ production and daily processes, whilst still maintaining desired power cost savings.

HVAC International awarded the supply and installation of Pamodzi Grootvlei, Shaft 3, automated dewatering pump control system to Pretoria-based engineering company, Iritron. This company’s experience in the fields of instrumentation, electrical design, control systems and information systems for industrial plants was a pre-requisite, and its track record made it an excellent candidate. Iritron also has an international footprint with some of its projects being implemented and executed in various countries in Africa and the Middle-East, the USA as well as India.

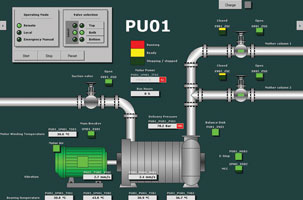

Based on a previous contractor’s incomplete design, the project began in June 2008 and the commissioning was completed in August 2008. The Iritron team worked within a tight schedule and budget. The automation of the pump station was a multistaged project. Iritron removed the existing manual control system and designed a fully automated remote distributed architecture solution. Siemens S7300 PLCs were installed, with TP177 touch panels for operator interfaces underground. An Adroit scada system was chosen as the HMI interface for the control system. This system was then integrated to the REMS pumping (realtime energy management system for pumping systems) system via an OPC server.

First, the PLC controlled remote I/O panels replaced the old local control panels so pumps could be controlled from the scada on the surface. Then, HVAC International’s REMS pumping system had to be connected via an OPC link to the scada to enable REMS pumping to have overall control of the pumps.

This system took care of the automatic pump shutdown during Eskom peak times, and sequential start-up of pumps after the peak time period. The Adroit scada system served as the entire interface between the HVAC International’s REMS pumping system and the PLC control system. So while the REMS pumping system only needs to communicate with Adroit via OPC, the system can also control any PLC system hardware through Adroit’s suite of over 100 drivers.

Chris Bosch from Iritron says: “The pumps were supplied directly from the 6,6 kV lines from the mine substation via HT switchgear and only the most basic status information was available from the motor control centre. We had to make the pump status indicated on the Adroit scada as intelligible as possible to aid the mine in fault finding when a pump trips.

“Adroit lent itself very well to developing the new design. While there was an existing example from a similar plant, its interface was extremely primitive and the scada was not very aesthetically appealing. Thanks to the WYSIWYG approach Adroit takes to provide graphic functionality, and the powerful interface, it was easy to upgrade the look and feel of the project and take the scada interface to the next level in the little time available for the project.”

In Pamodzi’s case, the new information available in the control room results in faster response to downtime, and gives early warning before failure. More efficient preventative maintenance is now possible, which is always less expensive than breakdown repair costs.

Benefits of the new system include:

* Electricity cost control via HVAC International’s REMS pumping control system.

* Remote supervision and redundancy (local and remote control).

* Centralised control – unlimited potential.

* Problem identification and rapid response.

* Robust communication network.

* Access to realtime information.

* Measurement, verification and automated reporting.

* Monitoring equipment maintenance – reducing breakdowns.

* Improving working conditions.

* Increased productivity.

* Operator friendly interface based on an easily expandable Adroit scada platform.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

| Tel: | +27 12 349 2919 |

| Email: | [email protected] |

| www: | www.iritron.co.za |

| Articles: | More information and articles about Iritron |

© Technews Publishing (Pty) Ltd | All Rights Reserved