The National Organization for Potable Water in Egypt contracts Bamag to construct three water treatment plants with a capacity of 800 litres per second.

The three plants are located at Shebin El Kom, El Baliana and Al Edwa, each featuring approximately 1200 I/O points. The aim was to automate process and system control using Beckhoff technology.

The first step of the potable water treatment process is clarification and filtering of the river water. Raw water to be treated is drawn from the Nile to the raw water sump pump, which serves as suction reservoir for the six raw water pumps contained in the pumping station. From here, raw water is passed into the flash mix chamber of the treatment plant. Clarified water is passed to the filter units via a clarified water channel and automatically controlled valves. All valves used for controlling the backwash procedure are controlled by a PLC. The filters are constant level type filters with the level controlled via a level sensor in each filter cell and a controller installed in the control desk of each filter.

Wash water pumps draw water from compartments in the wash water reservoir. Manual control is provided for the raw water chlorinators while automatic control is for the treated water chlorinators.

Automation objectives

Bamag’s aims for the automation of the control system included the following:

* Reliable system performance.

* Increasing plant productivity in terms of potable water quality and quantity.

* Safe operation regardless of operator mistakes.

* Maintaining the performance of each plant within the design limits without the need for deployment of expensive experts to respective sites.

* Cost-effective system support during the warranty period.

* General maintenance has to be simple so that it can be performed by the normal operating staff of the client.

* Minimum inventory of spare parts.

Due to the history of successful cooperation between Bamag and Industrial Control Systems, Cairo-based specialists for automation solutions and process control, ICS was awarded the contract for developing the control systems for the three water treatment plants. The control system was developed to be modular, expandable, cost-effective and rich in features, with an emphasis on reliability and minimum cost of system maintenance and support.

“After an elaborate task of evaluating and comparing systems offered by all major vendors, we came to the conclusion that they largely complied with our system requirements, but the initial cost and running costs were significantly higher when compared to the Beckhoff system,” Ahmad Sadek from ICS said. “The Beckhoff product range met all our criteria, and the CX Embedded PC and the Bus Couplers met our design objectives particularly well.”

The operating temperature and relative humidity were important factors for the decision to use Beckhoff products. At the three plant locations, two of which are in northern Egypt, temperatures during summer months can reach up to 50°C. Further benefits for the customer are the uniform design of the system components and their compatibility, which translates into minimum inventory of spare parts, and rapid training and familiarisation for the operating staff.

System control components

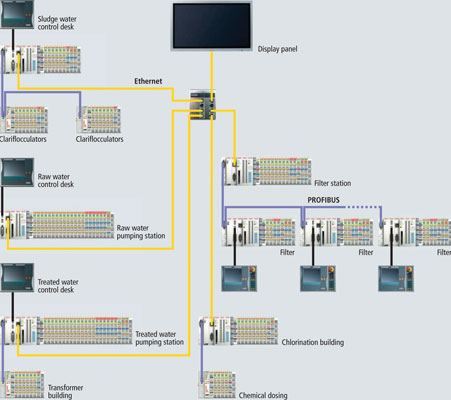

The control system consists of the PLC for automatic and manual functions, the control desks for manual operation and status feedback, and a mimic diagram for displaying the entire plant process flow diagram. Each part of the plant (sump pump for raw water, treated and sludge water, filtration system sump pump, chlorination and chemical dosing system) is equipped with a CX1000 that controls all functions. The filter system features 10 filters, each equipped with its own autonomous PLC (CX1000 with PROFIBUS interface) that controls the individual filter operations, both in automatic and in manual mode. The CX is networked via PROFIBUS with a master PLC that controls the backwash process according to the individual filter requirements. Due to the nature of the plant layout and the close interaction between events taking place at different parts of the plant, data have to be transferred from where they originate to where they are needed. In this way they become part of a complex protection or interlock scheme, leading to significant savings in cable runs, cost and time. Instead of using conventional hardwired control desks, the Beckhoff CP7831 and CP7832 Control Panels are utilised to function as the control desks.

PID soft controllers are used throughout the plant for level, pressure and flow control. The integration of the PID soft controllers into the Beckhoff system proved to be highly efficient. The entire plant is networked via Industrial Ethernet with a transfer speed of 100 Mbaud. The system achieves a response time of less than 10 milliseconds, ensuring a high degree of integrity. The traditional central mimic diagram was replaced with a large plasma display that provides real-time dynamic display of the central plant.

| Tel: | +27 11 795 2898 |

| Email: | info@beckhoff.co.za |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved