After time, temperature is the second most measured physical unit in production. Temperature is an important indicator of product quality, safety and equipment conditions.

Infrared thermometers in industry

During the last five years the IR sensor market has seen two major trends. Firstly, IR thermometers are significantly lower in cost. The most expensive parts of an infrared thermometer are the lenses and detectors. New lens materials and technologies and mass production of IR detectors for consumer products such as toasters, hair dryers and ear-thermometers, have resulted in lower prices for these two important components.

Secondly, IR sensors are becoming smaller in size. In the past, the measurement of low temperatures made it necessary to use fast (low F number) lenses with relatively large diameters in order to capture enough emitted energy. Progress in detector technology and the use of micro system techniques together with improved preamplifier designs have helped reduce the dimensions of the IR-sensing head dramatically. Because the newer sensors have better response characteristics they require less energy to achieve a usable signal, resulting in smaller lens diameters.

Detector and optics

There are two main groups of detectors found in IR thermometers – thermal and photoelectric or photon detectors.

Thermal detectors change their own temperature in response to heat radiated from the process under measurement. Similar to a thermocouple, this produces a corresponding voltage fluctuation proportional to the change in temperature.

Photoelectric detectors (eg, photo diodes) react to the level of photon bombardment which causes a variation in the current flowing through the device.

Thermal detectors respond less quickly than the photoelectric detectors because they have to feel a temperature change. In the case of thermal detectors slow means time constants in the millisecond range compared to nano or microseconds for photoelectric detectors.

Choosing the correct IR unit

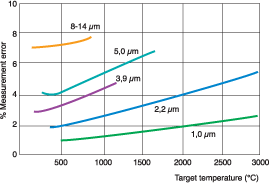

Selecting a device with the correct operating wavelength for the temperature under measurement has a significant influence on the accuracy of the results. It is best to use the shortest possible wavelength and Figure 1 indicates the common wavelengths used with respect to target temperature and error. From this it can be see that to measure above 900°C users should not use the common 8-14 micron types, but should rather opt for a 1 or 2 micron wavelength.

Trends in electronic design

Due to the increasing expectations of users and competition among manufacturers, infrared thermometers are continually being improved and electronic design is an area that has seen the most improvements recently.

Process industries continue to need sensors with higher accuracy and repeatability as they look for ways to cut costs, maximise their production lines and monitor quality. Easy installation, use and maintenance continue to be important, as does the ability to withstand harsh environmental conditions. Field checking and field calibration features are becoming more and more important as companies look to optimise their personnel and equipment resources. Manufacturers need IR sensors with a wide operating temperature range that cover more applications and eliminate the need for cooled housings, to keep the costs down.

Manufacturers are taking advantage of the many developments in other industries to continue to expand the capabilities and efficiencies of the IR thermometer. These advances have made a variety of products readily available and affordable where previously they were only used for specific military applications because of the associated cost.

Advances in the cost/performance ratio of detectors and optics are helping expand the applications where IR can be used effectively and yield a better return on investment. Two colour or ratio measurement and units with built in visual cameras are some of the most recent advances.

| Tel: | +27 11 608 1551 |

| Email: | [email protected] |

| www: | www.randci.co.za |

| Articles: | More information and articles about R&C Instrumentation |

© Technews Publishing (Pty) Ltd | All Rights Reserved