Ana-Digi Systems and Adroit Technologies teamed up for the Klawer project in 2005 to ensure that Klawer remains one of the major players in Cape Town as a leading producer of quality wines.

Klawer, situated in southern Namaqualand 260 km from Cape Town, required a no-nonsense, easy to use, reliable solution for its wine tank control system along with world class support and back-up.

It was decided to use the LS GM4 PLC and LS iG5 inverters as the basis for a reliable and flexible control system. Adroit Scada was chosen as the preferred operator interface medium as it offered ease of usage, flexibility, good graphics and expandability. As Adroit Technologies is a South African-based company, the client was further assured of continued service and support.

In 2005, Klawer Wine Cellars had virtually no tanks for fermentation and maturation of wines. It acted as a receiving depot for grapes from the area, but once crushed, the grape juice had to be pumped into container vessels and trucked to Trawal Wines, a sister winery some 20 km away, for further processing.

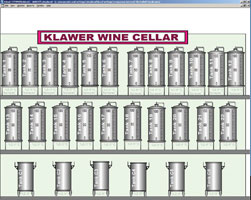

The decision was made to process its own wines under its own name of Klawer Wine Cellars. A refrigerated hall was built and the order was given for the manufacture of 12 maturation tanks and 10 fermentation tanks. The rapidly expanding local wine industry required new solutions for handling the ever increasing grape yields from the Klawer area. It offered Klawer Wine Cellars the opportunity to become a major player in the handling, processing and sale of wine in the region.

The 10 main fermentation tanks are used mainly for white wine processing, or for temporary wine storage. Six more fermentation tanks have since been added to supplement the needs of the plant. All the fermentation tanks are equipped with temperature probes and solenoid valves for controlling wine temperature. Cold glycol is pumped through the jacketed walls of the tanks for cooling, and temperature set-points are entered via the Adroit Scada system.

The 12 maturation tanks are used mainly for processing red wine, which requires more care and longer processing than white wines do. For this purpose, the maturation tanks are equipped with more equipment such as stirrers fitted on the bottom of the tanks and pumps for recirculating the wine. Sprayer nozzles on the top of the tank ensure an even distribution of the recirculated wine over the top surface of the tanks.

The maturation tanks are likewise cooled by glycol being pumped through the walls of the tank. Temperature probes and solenoid valves allow for temperature control; pressure transducers fitted into the bottom of the tanks are used for tank level indications and pump low level safety monitoring.

During maturation, the temperature control of the tanks is critical, as the grape yeast and fermentation process generates a lot of heat in the tank. A cake of grape skins and husks forms and tends to float to the top of the tank. If not controlled, the wine can overheat and the cake can solidify. The cake would then require forceful breaking up to remove once the wine is pumped out of the tank.

The solution is to continuously stir the wine in the tanks and to cyclically recirculate the wine. Recirculation allows for wetting of the cake by spraying the wine back into the top of the tank. Pumps are equipped with LS frequency inverters which are used to vary the pump speeds. The varying pump pressure ensures that the whole of the cake is sprayed.

Critical variable parameters such as temperature set-points, pump cycle times and variable pump speeds are all addressed through the Adroit Scada screens. Once set up, the system runs automatically day and night during the wine processing season.

Klawer Wine Cellars has become a major player in the area as a leading producer of quality wines within a short space of time. Not only does it produce its own wines, it matures wines for many neighbouring wineries as well. The streamlined handling process has drawn in farmers from far and wide to deliver their grapes to Klawer Wine Cellars. In certain cases, the farmer can choose to get paid for the tonnage of grapes delivered or on yield quantities after crushing, the tank level control is used for determining the wine yield quantities.

Support and backup is provided by Ana-Digi Systems of Cape Town. The flexibility of the system allows for easy expandability up to 32 remote stations. At present, the remote GM6 PLC, required for the new fermentation tanks, is connected on a LS F-Net bus system. F-Net is an LS fieldbus network which is fast, reliable and easy to set up. User friendly operator interfacing via Adroit Scada means that relatively unskilled workers can operate the system. Seamless expansion of the Scada package and version compatibility has been vitally important over the last four years.

The control system has recently been expanded. The Adroit Scada package has since been upgraded from 150 to 300 scan points, and the LS GM4 PLC has been expanded to include a remote GM6 slave rack, when six new fermentation tanks were added at the end of 2007.

The relationship between Adroit Technologies and Ana-Digi Systems has provided many of its clients with a proven and trusted solution to their automation needs. The support and backup provided by Adroit Technologies is fully appreciated by both Ana-Digi Systems and its clients. In the future, this combination of Adroit Scada and LS PLC equipment will continue to provide many more users with the same peace of mind that their automation needs have been fully met.

For more information contact Keith Gross, Ana-Digi, +27 (0)21 914 9030, keith@anadigi.co.za or Dave Wibberley, Adroit Technologies, +27 (0)11 658 8100, davew@adroit.co.za

| Tel: | +27 11 658 8100 |

| Email: | info@adroit.co.za |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved