Conveyor belt condition monitoring

November 2008

Maintenance, Test & Measurement, Calibration

VisIndex, the advanced conveyor condition monitoring system developed in South Africa by Westplex, has

successfully proved itself in the field to be an essential conveyor belt condition monitoring and maintenance tool.

Westplex’s VisIndex conveyor inspection system combines the power of a high resolution computer-based visual inspection system with the diagnostic ability of a computer-based inductive sensor system, to provide a comprehensive measurement of a conveyor belt, detecting both surface defects and buried steel cord faults. These measurements have been successfully and reliably made on belts of up to 17 km long, running at 6,5 metre/sec.

VisIndex has been proved to be capable of detection of:

* Cord defects consisting of partial or full cord breaks caused by mechanical damage and/or corrosion.

* Detection of changes in splices.

* Detection of new defects and changes in existing defects.

* Surface defects, resulting from damage to the belt surface or edge.

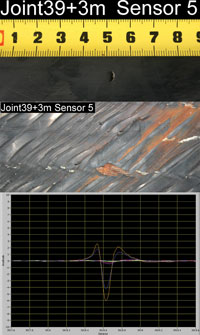

Surface cord damage – magnetic signature

Scanning principles

By use of a line-scan camera, used in conjunction with a high intensity LED line-light, the system acquires and records a single high-resolution image (2 mm/pixel or better) of the whole of the conveyor belt, while it is running at its normal speed.

An inductive sensor simultaneously senses changes in the steel cords that are buried in the belt, to detect splices, and defects in the cords. The pattern of distribution of splices, which is unique to each belt, is used to locate the position along the belt of any visual and inductive defects that are detected. The inductive sensor can monitor up to 16 sections across the belt so that the location across the belt of defect and splice magnetic signatures can be determined. The line-light and magnetic sensors were designed by Westplex, and are manufactured in South Africa.

Condition monitoring

The conveyor belt is initially characterised by the performance of a ‘reference’ inspection that measures the belt length, locates, measures and records the magnetic signature of splices and defects, and records a surface image of the entire belt.

Viewing and comparison tools that show coordinated surface images and magnetic signatures, can be used to examine reference data for initial visual and/or magnetic defects that may be problematic.

When subsequent inspections are made, the measurements are automatically synchronised with the reference data positions along the belt, so that comparisons can be made. Progressive changes in the belt condition are monitored by the comparison of inspection data with the reference data and/or earlier inspections. The viewing and comparison tools highlight changes in splices, defects and surface defects, and generate a condition report.

Condition reports

The VisIndex software package, developed by Westplex, provides a comprehensive set of automated measurement, comparison and report generation tools. VisIndex automatically generates a belt condition report that shows the current state of the belt, and highlights changes in the belt condition. The report can be printed or saved in HTML or pdf format.

Further reading:

Keeping lifting equipment safe and securely on track

Maintenance, Test & Measurement, Calibration

In the hustle and bustle of mining production, the focus on the servicing of lifting equipment can unintentionally be sidelined. This situation can easily be avoided with a customised Konecranes Service Agreement that offers a comprehensive and systematic approach to asset management.

Read more...

Tablet oscilloscope

Vepac Electronics

Maintenance, Test & Measurement, Calibration

The PeakTech 1212 is a new, innovative oscilloscope designed to resemble a standard tablet in size and form. This tablet oscilloscope allows users to record any common measurement quantity and type, just like a desktop oscilloscope.

Read more...

Powerful test controller

Maintenance, Test & Measurement, Calibration

XJTAG is launching the XJLink-PF20, brings the same dependability and robustness to a new 4-TAP two-port configuration, and offering both functional and JTAG boundary scan testing with the XJTAG testing suite’s long-established power and control.

Read more...

Multichannel AWGs for GHz signal generation

Vepac Electronics

Maintenance, Test & Measurement, Calibration

Spectrum Instrumentation has introduced its new flagship Arbitrary Waveform Generators from the company’s Netbox series, an easy-to-use instrument line that can be controlled via an Ethernet cable from any PC or network.

Read more...

The smart choice for test and measurement solutions

RS South Africa

Maintenance, Test & Measurement, Calibration

As the demand for precision and efficiency continues to grow across industries, RS PRO, the own brand of RS, provides a complete portfolio of test and measurement equipment engineered to meet the highest standards of performance, safety and value.

Read more...

New frequency counter with 10 digits of resolution

Comtest

Maintenance, Test & Measurement, Calibration

B&K Precisio has a new series of universal frequency counters designed for a wide range of frequency measurement applications.

Read more...

Verification using Heartbeat Technology is a breeze

Maintenance, Test & Measurement, Calibration

Heartbeat Technology reflects Endress+Hauser’s long-term commitment to enhancing measurement reliability and efficiency across a growing product portfolio.

Read more...

Clog-resistant nozzle for powerful stationary tank cleaning

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Clog-resistant nozzle for powerful

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Why your next oscilloscope should

Comtest

Maintenance, Test & Measurement, Calibration

The PC-based USB oscilloscope is a cutting-edge, adaptable alternative to traditional benchtop oscilloscopes that’s redefining test and measurement.

Read more...