Innovative network design

September 2008

Fieldbus & Industrial Networking

Industrial Ethernet in VW-Golf production.

Increasing expectations on the side of the consumer with regard to safety, environmental protection and comfort, combined with increasing pressure to cut costs poses challenges for the automobile industry. With regard to efficiency, transparency and magnitude, the Wolfsburg production line of the fifth Golf generation of Volkswagen sets new standards; an innovative Ethernet structure services the complete manufacturing facilities and offers increased saving potential. Wolfsburg is the main production location for the fifth Golf generation.

In its fifth generation, the Volkswagen Golf offers more than ever. The compact wagon is available with different types of drives, transmissions, engines, and equipment. But all models are the same concerning active and passive safety. The clear advantage with regard to car body stability and crash safety, which was awarded five stars in the Euro-NCAP-Test, is combined with significant weight optimisation. 140 special robots with a total of 70 metres of laser-welded seams provide body stiffness. The predecessor had only five metres.

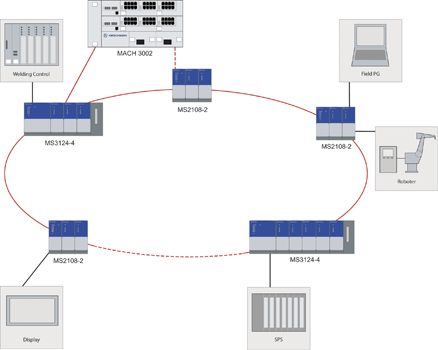

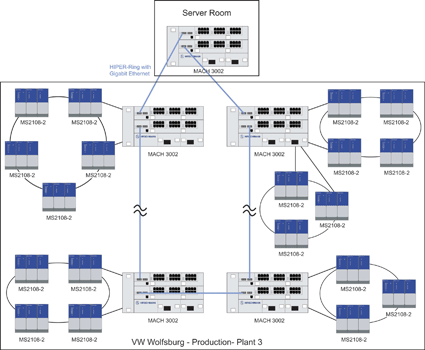

Network diagram

Project parameters

In Wolfsburg, the largest vehicle/automobile plant in the world is combined with the largest production network in the world in the automobile construction industry. For decades the car has been the heart of the city's economy.

The seamless generation change enables the timely planning and completion of new production lines. In 2002, the most modern production plants in halls 1 (pressing plant), 3 and 4 (body shell work), 15b (paintshop), 54 (assembly) and 12 (discharge) were established. The production capacity of the Wolfsburg location covers 4000 vehicles per workday. Dynamics and transparency at all levels of the company must be ensured through realtime, constant communication.

Implementation

Highlights of the chosen network architecture include:

* 16 modular backbone-switch MACH 3000 in redundant HIPER-ring structure span all halls throughout the production plants. For a clean IP-sub network structure in all areas of production, as well as the incorporation of the MACH 3000 systems in the communication network, enabled by redundantly connected M-Router modules. The Ethernet backbone for manufacturing of the body operates at Gigabit speed, using optical fibre for transmission.

* More than 1500 rail-switch systems, MICEswitches mainly MS2108 and MS3124, in over 100 HIPERrings, which are connected to the plant network via redundant optical fibres, link the cells and ensure the highest level of availability.

Requirements

The scale of the system is illustrated by the fact that it has to cater for:

* 8000 operators.

* 1000 robots.

* 10 000 IP-addresses.

* 2900 cars/day.

* Laid LWL cable > 1000 km.

* Exchange and update of components during operation.

* High temperatures.

* High EMV.

* End-to-end management.

* Redundant network design.

* Possibility of simple diagnosis.

For more information contact Profitek Industrial Communication, +27 (0)12 664 4998, [email protected], www.profiteksa.com

Further reading:

Beckhoff expands economy drive system

Beckhoff Automation

Fieldbus & Industrial Networking

Beckhoff’s new AM1000 servomotor joins the company’s economy drive system. The compact, powerful motor and the AX1000 servo drive provide users with a perfectly coordinated, cost-optimised drive system.

Read more...

CC-Link IE Field supports egg carton production

Fieldbus & Industrial Networking

Huhtamaki’s Franeker plant in the Netherlands manufactures more than 11 million egg cartons every week using recycled paper. To support its highly automated lines, the site has begun upgrading its automation systems from older serial network standards to CC-Link IE Field, an open industrial Ethernet technology that offers faster performance due to gigabit bandwidth and better diagnostics.

Read more...

Ultra-compact industrial PCs exploit advances in CPU technology

Beckhoff Automation

Fieldbus & Industrial Networking

Beckhoff’s C60xx scalable series of ultra-compact industrial PCs combines high computing power in an extremely compact format with a wide range of options for installation in the control cabinet.

Read more...

How to protect your industrial network

RJ Connect

Editor's Choice Fieldbus & Industrial Networking

Network security is no longer a matter of preventing hacking or data breaches. Traditional defence mechanisms for perimeter protection may not fully address internal threats or device-level vulnerabilities alone.

Read more...

High-speed precision and simplified architecture for slicing systems

Fieldbus & Industrial Networking

When KFT Food Machinery needed a way to support ultra-fast, multi-axis motion control in its slicer range, it turned to CC-Link IE TSN – the open industrial Ethernet technology from the CC-Link Partner Association (CLPA).

Read more...

Precise, synchronised control for automated steel mesh handling system

Fieldbus & Industrial Networking

Automation specialist Hambi Maschinenbau has developed a world-first system that automates the cutting, handling and stacking of heavy reinforcing steel mesh – a task that previously required up to six human operators.

Read more...

Loop Signature Part 2-1: Loop signatures and process transfer functions

Michael Brown Control Engineering

Fieldbus & Industrial Networking

The previous series of loop signature articles dealt with the basics of control loop optimisation, and concentrated on troubleshooting and ‘SWAG’ tuning of simple processes. In this new series, consideration will be given to dealing practically with more difficult issues like interactive processes, and with processes with much more complex dynamics.

Read more...

Smart and seamlessly integrated I/O upgrade

Beckhoff Automation

Fieldbus & Industrial Networking

Beckhoff’s entire portfolio of EtherCAT terminals is now undergoing a technological upgrade while remaining fully compatible with the existing series.

Read more...

Introduction to Part 2 loop signatures and process transfer functions

Fieldbus & Industrial Networking

The previous series of loop signature articles dealt with the basics of control loop optimisation, and concentrated on troubleshooting and ‘SWAG’ tuning of simple processes. In this new series, consideration will be given to dealing practically with more difficult issues like interactive processes, and with processes with much more complex dynamics.

Read more...

Siemens sets new standards in drive technology

Fieldbus & Industrial Networking

Siemens is setting new standards in industrial drive technology with the launch of its new high-performance drive system, Sinamics S220. This offers a seamless and innovative drive system with comprehensive simulation and analysis capabilities and advanced connectivity features that enable full integration into digital work processes.

Read more...