Improving efficiency and increasing contribution margin from the production and sale of heat and electric power are among the main objectives in thermal power plants (TPP) around the world.

However, many TPPs face problems in optimal load distribution and optimal planning of equipment, operational monitoring of key performance indicators, as well as avoiding penalties by minimising harmful emissions.

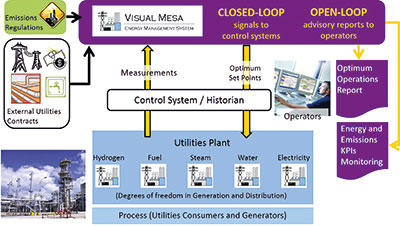

Currently, the solution for such issues is not possible without the use of modern computer techniques and information technologies that can be attributed to systems-level MES, and Yokogawa believes that Soteica Visual MESA offers a compelling solution.

The basis of Visual MESA serves as an integrated model of all energy flows. In addition to energy units, the system considers money equivalents of energy flows, which is a necessary condition for the solution of minimising energy costs and maximising profit from the sale of thermal and electric energy. The system has an intuitive environment for adjustment, maintenance and modernisation of the design decisions of the system through the built-in library of pre-configured functional blocks with a graphical way to organise data flows between functional units by means of communication lines, which also contain thermodynamic and energy characteristics of the process streams (pressure, temperature, enthalpy, calorific value, and heat capacity).

Visual MESA allows Yokogawa to obtain the results of the optimisation of the distribution of thermal and electrical loads, the planning and configuration of the power equipment, with the aim to obtain the maximum profit from the sale of heat and electric energy, based on forecast data for the price of electric energy, heat consumption requirements, and the composition of the equipment for the days ahead, including the possibility of operational adjustments. Also, additional constraints on emissions (the single integrated model can account for and calculate emissions of CO2, SO2, NOx based on the stoichiometry of combustion and correlations), contract penalties and restrictions (e.g. strict selection of the natural gas in equal parts), and technological limitations (e.g. minimum downtime of the boiler, the simultaneous startup of equipment, etc.) can be incorporated.

Yokogawa believes that Visual MESA provides the most accurate optimisation solution in the energy sector, which can be configured specifically for use with the systems that generate steam and electricity. Unlike some software available on the market, it allows Yokogawa to solve problems in large-scale system modelling and optimisation.

Features

Visual MESA provides users with the following key features: monitoring, auditing, accounting, calculation of key performance indicators, operational reports, and optimisation and planning.

Although applicable to almost all industries, Visual MESA specifically for TPP contains a combination of two sets of functional licences:

• Visual MESA ERTO Open Loop (energy real-time optimisation) with recommendations for optimal use in a report).

• Visual MESA-MPO (multi-period optimisation for optimal planning of equipment configuration to time limits, e.g. maximum or minimum uptime). This module operates offline.

Economic benefits

The primary economic effect in the implementation of Visual MESA is achieved by implementing the following functions:

1. Optimisation of the distribution of energy flows

• Operation optimisation of loads of parallel running equipment (boilers, turbines).

• Choice of the cheapest energy source taking into account production, environmental, and contractual constraint.

2. Optimal planning and scheduling

3. Leveraging utilities auditing and accounting features to detect and eliminate wasted steam

• Identification of wasted steam and operating problems.

• Alerting for changes by periodic scan of all the flow meters inside the model and warning of any changes that occur which exceed predefined thresholds.

4. Emissions management and monitoring

• NOx and SOx constraints.

• CO2 trading (according to Kyoto Protocol).

• Equipment performance monitoring.

• Utilities planning and scheduling.

5. Evaluate effect of production plans on utilities system

6. Planning of shutdowns

7. Export nominations

8. Investment planning and basic engineering

• Plant expansion, process changes.

• Change of configuration of the energy system (e.g. a new co-generation unit).

9. Soft cost savings can be found through allowing the entire organisation:

• To access the site-wide energy system through one model and one environment.

• Visibility into all the decision variables and associated constraints (which are sometimes hidden or ignored).

• Optimal centralisation of system responsibilities.

In addition to direct benefits from the introduction of Visual MESA and new approaches to monitoring energy efficiency, TPPs will receive a number of additional advantages:

• The possibility of convenient analysis of the operation of energy systems in real time, the availability of direct access to the indicators of the entire energy system of site from a unified model and a unified environment.

• Ability to monitor all process variables and related constraints, which in some cases may not appear or be ignored.

Conclusion

The economic benefits from the implementation of Visual MESA are estimated to be in the range of a 1-5% increase in power plants. Thus, the implementation of MES technology is an important tool for solving problems in maximising the marginal profit of TPPs, optimising and improving operational processes in the planning regimes, and the composition of power equipment within the requirements of energy and environmental management.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved