The Association for Sensors and Measurement Systems estimates the number of manufacturers of industrial sensors and measuring systems in Europe to be around 1000 companies. In total, there are about 3000 European companies that work in the field of sensors, including manufacturers, retailers, engineering offices and specialised service providers. GHM Messtechnik is one of these companies. In 2007 it developed the vision of combining different areas of expertise and profiling itself as a hidden champion for the development of customer-oriented solutions that are appropriate for the market.

The GHM Group, consisting of Greisinger, Honsberg, Martens, Imtron and the Italian environmental measuring technology manufacturer Delta Ohm, currently concentrates on bundling the synergies of these five tradition-based companies. The Martens operation has been focused on producing hygienic sensors for conductivity and temperature for several years. This has been expanded over time into a complete product portfolio of modern compact sensors for breweries and beverage producers. Two application examples from these areas are described below.

Yeast monitoring

Multi-function tanks are often used in modern breweries with the objective of avoiding frequent product changeover. They are also used for the fermentation process, where the yeast settles in layers in the lower portion of the tank. In order to be able to work efficiently, the dead yeast cells must be separated from the active ones. To ensure this, the lowest layer of dead yeast is removed from the tank in an initial step. Then the next layers are separated from still fermentable yeast and beer in further steps. For this purpose, a turbidity sensor is installed directly at the tank outlet or in the yeast return line. This sensor measures the turbidity of the yeast/beer mixture flowing through it, independently of the colour.

At the end of the storage or maturation time, the majority of the yeast remaining in the tank has now settled as lees. Since this portion of the yeast is decisive for quality, it should be separated from the beer as precisely as possible when emptying the tank. This phase separation is also monitored by the available turbidity sensors, where it is important that the turbidity value is measured as precisely and reproducibly as possible.

In this way the possibility of product contamination and beer losses is eliminated, and as a result, consistent beer quality can be assured. The turbidity value, which is directly output as a 4-20 mA current signal, or alternatively via a pre-adjusted limit-value contact, can also be used with an external unit for control of downstream valves, including delivery to a membrane filter unit or in the storage tank.

The MAT433/437 turbidity meter is particularly suited for the above measurement applications.

Small batch production and individual beer types

For the production of small batches and individual types, in 50 litre vats, for example, the GHM Messtechnik Group offers new measuring and regulation components for the equipment of small breweries. This makes it possible for dedicated regional brewers, and even home brewers, to achieve a verifiable process with strict adherence to the recipes that they have created. The desired beer is the result of an individualised recipe based on experience and creativity.

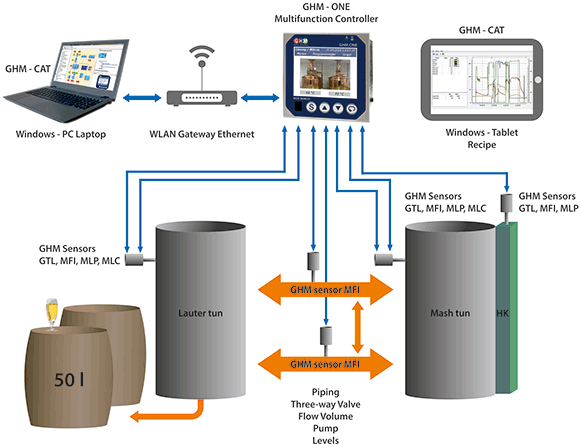

For this purpose, modern measuring and regulation technology is used in combination with state-of-the-art communication technology for simple and transparent use. A compact GHM-ONE multi-function regulator mounted directly in the system processes all measurements of the sensors certified for food production. These include temperature sensors and flowmeters, as well as fill level sensors and limit level switches, which can recognise two different media by their capacitive properties, such as beer and foam. The GHM-ONE can then communicate the appropriate control commands to the heating and cooling units, pumps, three-way valves and stirrers in the system. The colour display of the regulating device shows the operator the current status of the recipe process and the quality of all regulating circuits, and provides graphic and text-based instructions for the progression of the process. The operator confirms these locally on the unit’s touch display.

A special feature is the individual recipe specification developed for the practitioner, based on a clearly arranged table containing the individual steps and associated parameters. This shows the brewer the individual recipe ‘step-by-step’ as specified for the process, which can be viewed on the screen of a laptop, industrial PC or tablet. The independently operating multi-function regulator communicates with these devices using its integrated Ethernet interface, or wirelessly via a standard WLAN gateway. With these devices positioned conveniently alongside the production system, the specially developed GHM-CAT tool runs the new ‘Beer production program editor’ function, which simplifies the operation of a brewing system. The brewer creates the necessary steps according to their mash method of choice and enters specifications for the exact parameters of the temperature profiles, holding times and step-enabling conditions, the duration and number of pumping processes between the mash tank and lauter tun, the corresponding heating and cooling processes, as well as the variable repetition processes for mash processing.

With this clear representation of the recipe in the logical sequence of process steps, and the corresponding set-points and actual values, the brewer can follow the progression of the brewing process at a glance. In addition to monitoring for quality control and documented verification, the brewer is also provided with graphical trend representation and selectable process data reports to record batch production data.

This brewing solution offers all creative beer brewers, and their system integrators, a professional, transparent, individualised process platform that is suitable for small or larger batches. The clearly arranged system aids in creating new taste experiences from a beverage that has been appreciated for hundreds of years, and reproducing them in the form of unique recipes.

“We see many opportunities for our range of hygienic instrumentation in the South African food and beverage market,” commented Jan Grobler, managing director of GHM Messtechnik South Africa. “From the hygienic flowmeters, level and temperature transmitters, through to the precise benchtop measurement devices, the accuracy, reliability and quality of our technology is what gives us an edge in this sector.

“We recently introduced the GHM Messtechnik Turbidimeter, MAT 433/437 which is used for phase detection in the food and beverage industry. The absorption measurement principle, according to EN ISO 27027, is designed to measure very high turbidity values, which are output as a percentage of the maximum measurement value. This can be converted via an integrated conversion table into material-specific concentrations, or into the formazine based unit FAU. This is a very high-tech measurement device designed to eliminate waste in the brewing process.”

For more information contact Jan Grobler, GHM Messtechnik South Africa, +27 (0)11 902 0158, info@ghm-sa.co.za, www.ghm-sa.co.za

| Tel: | +27 11 902 0158 |

| Email: | jan.grobler@senseca.com |

| www: | www.senseca.com |

| Articles: | More information and articles about Senseca |

© Technews Publishing (Pty) Ltd | All Rights Reserved