As a long-term active partner of the OPC Foundation, Beckhoff was among the earliest adopters to implement the OPC UA standard in many innovative ways. Adaptation milestones that benefitted Beckhoff’s customers occurred in 2007 (world’s first PLC with integrated OPC UA server), 2010 (first PLCopen-standardised UA client modules from Beckhoff), 2012 (free UA server for industrial PC diagnostics), 2014 (SoA PLC), 2016 (UA information models in the PLC) and in 2017 (publisher-subscriber model in the PLC).

Development milestones

The first OPC UA server was already introduced in 2006. In 2007, it was officially offered as a TwinCAT software supplement product and installed in the first customer projects. Following its certification in 2008, the ‘TwinCAT OPC UA Server’ rapidly developed into one of the most popular TwinCAT supplement products in the connectivity segment, impressing users with its continuous advancement and integration of the latest OPC UA functionalities.

Another milestone was the development of the so-called SoA-PLC (Service-oriented Architecture PLC), which began in 2013. This enables the development of service functionalities based on IEC 61131-3 methods within the PLC, and their availability via the TwinCAT OPC UA Server as OPC UA methods. Such methods enable OPC UA clients to use these services and benefit from their consistent processing and assignment of input and output parameters. With the rising popularity of OPC UA in various industries, many more so-called companion specifications have been published in recent years. These specifications define the information model mapping from the protocol being used in the respective domain to OPC UA.

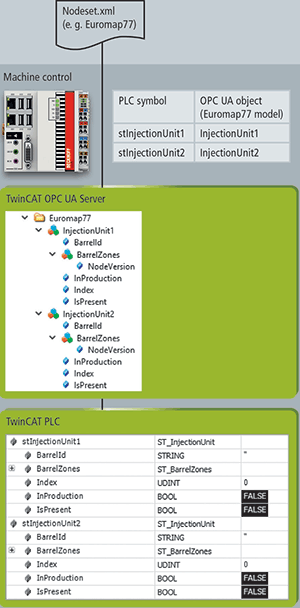

One such example is the Euromap77 standard for injection moulding machines in the plastics industry. To provide the secure and standardised exchange of information between various platform manufacturers, the Euromap77 model was mapped to OPC UA in the form of a companion specification. The TwinCAT OPC UA Server is based on the IEC 61131 mapping from PLCopen by default. Using this specification, the IEC 61131-type system of the TwinCAT PLC is loaded into the OPC UA namespace. A generic expansion of the server now makes it possible to load any information model. Normally, these information models are available in form of an XML file that defines the type system. The companion specification of the Euromap77 model is one of these. The TwinCAT OPC UA Server builds its type system by importing the respective companion XML, and combines the objects of the XML with variables from the TwinCAT PLC. A linked OPC UA client can now browse the server based on a standardised type system (Euromap77) and access the objects contained therein.

Security enhancements

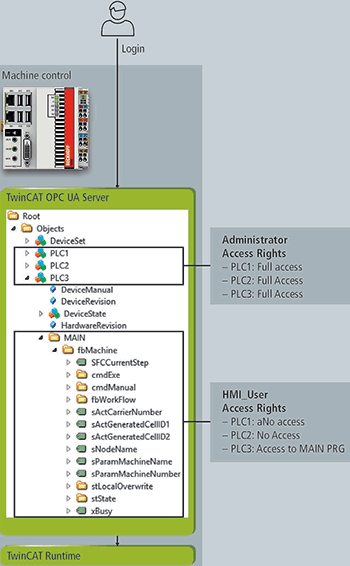

Enhancements in the security model of the TwinCAT OPC UA Server enable the programmer to define various users and user roles, and assign access levels to the individual namespaces and objects. This makes it possible to further protect the already secure communication and client-server authentication that uses X.509 certificates.

Architecture enhancements

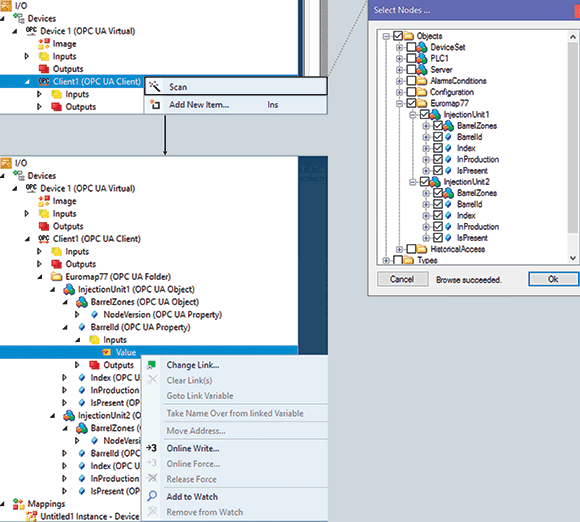

In 2012, an OPC UA Client was added to the TwinCAT OPC UA supplement product making it possible for PLCs to establish a direct connection to OPC UA servers on the basis of PLCopen function blocks. It also made it possible to call up methods from an OPC UA Server immediately, which enhanced the SoA PLC concept even more. To increase the usability of the TwinCAT OPC UA Client, this functionality is now available in form of a TwinCAT 3 I/O device. As a result, the user no longer needs to write any PLC code to read or write data from or to a remote OPC UA server (or to call up methods). A user can simply insert the respective symbols into the TwinCAT XAE I/O configuration and link them to other symbols via regular mapping mechanisms. This is where the mapping mechanism that is integrated into XAE comes into play again: It establishes a link to the OPC UA server, and the symbols are automatically read and created.

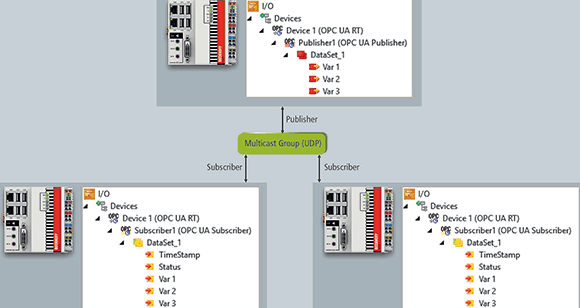

The expansion of the OPC UA specification with publisher-subscriber (pub/sub) communication patterns enhances the classic client-server architecture with modern communication mechanisms that enable multi-cast communication in the local machine network, as well as broker-based communication via a cloud service. Beckhoff presented this feature as a real-time-capable prototype at the 2016 SPS IPC Drives trade show. This meant Beckhoff was the first automation technology supplier to implement this pub/sub technology for deterministic M2M communication. The solution is configured via a separate I/O device in TwinCAT XAE.

PC-based control technology

With the company’s PC-based control technology, Beckhoff supplies the ideal platform for Industrie 4.0 automation projects. After enabling the standardised exchange of data via OPC UA for many years, it has become even better with additional new features that improve the modelling of type systems, security and usability. In addition, OPC UA is offered in more places than just the TwinCAT supplement products. Every Beckhoff industrial PC is delivered with a free OPC UA server for IPC diagnostics by default. This software can read hardware information such as the CPU or mainboard temperature and initiate file uploads or downloads via OPC UA. Complete directories or individual files can be shared via OPC UA so that OPC UA clients can use this file transfer component to exchange files with the OPC UA server, for example to download log files.

For more information contact Kenneth McPherson, Beckhoff Automation, +27 (0)11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved