Pyrogen has achieved the SABS mark in respect to SANS 15779: 2012: ‘Condensed Aerosol Fire Extinguishing Systems – requirements and test methods for components and system design, installation and maintenance – general requirements’. It is the first aerosol fire extinguishing system to achieve this approval.

To attain an SABS mark, a product must pass testing against the SANS. Further, the manufacturer’s production facility will also be inspected by the SABS to determine whether it has adequate quality assurance systems in place (such as SABS ISO 9001) to ensure that product quality can be maintained consistently. Additionally, the SABS will conduct ongoing audits of the quality management system, along with regular and ongoing tests of the product obtained from either market outlets or the factory.

This peace of mind for the buyer is, in turn, a great marketing tool for the producer. The SABS mark is an icon that it can display proudly on its products.

What is Pyrogen

Pyrogen arose out of the development in the former Soviet Union of a solid fuel for rockets. This fuel provided propulsion, but no trailing heat or flame path to guide heat-seeking missiles or alert thermal radar systems. By using a derivative of the solid rocket fuel with chemical fire fighting properties, combined with flame suppression coolant, the Soviet science laboratory, Soyuz, was able to develop a remarkable and highly effective fire suppression system.

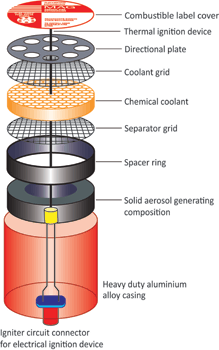

Pyrogen consists of a solid aerosol-generating chemical and a solid chemical coolant. It is a thermo-plastic mixture consisting of a solid potassium nitrate based oxidiser, a plasticised nitrocellulose based combustible binder and patented technological additives.

When activated, the solid-generating chemical undergoes a combustion reaction producing potassium carbonates (KHCO3, K2CO3), carbon dioxide gas, nitrogen gas and water vapour (H2O(g)). This mixture represents the actual extinguishing agent.

As the reaction temperatures are high, potassium carbonates are formed in gaseous form, but as the vapour cools these condense to a liquid and then a solid.

As solid potassium carbonates are produced by condensation, the particle size is very small, approximately one micron. Micron sized solid particles mix with the gaseous carbon dioxide, nitrogen and water into a uniform homogeneous gas-like aerosol. This aerosol displays three-dimensional distribution and suspension times of up to 60 minutes.

As a combustion product, Pyrogen aerosol is hot upon formation. Although it is more effective in terms of the actual extinguishing action when in its hottest state, the negative impacts of very high temperatures are obvious. Ejection of flame at the discharge outlet and poor distribution of the aerosol within a protected enclosure is the main problem and has to be eliminated. Attempts to replicate Pyrogen by other manufacturers have been unable to overcome these negatives.

Pyrogen has a second unique formulation, the solid chemical coolant which comes into action eliminating the problems highlighted above.

When the hot Pyrogen aerosol passes through the coolant, the coolant decomposes absorbing a great amount of heat, it is a polymer composition highly impregnated with endothermic ingredients – substances that decompose at 200–300°C without melting, generating gases and absorbing approximately 400 calories of heat per second.

How it works

Application of Pyrogen coolant enables flames to be arrested at the discharge outlet and thus it provides a uniform distribution of the aerosol within the area, which contributes to the reliability and safety of the extinguishment. Moreover, the inert gases formed during thermal decomposition of the coolant contribute to the effectiveness of the extinguishment.

Primarily, Pyrogen’s extinguishing action is achieved by interfering chemically with the fire reaction. Two chemical mechanisms take place:

1. Removal of flame propagation radicals ‘chain carriers’ OH, H, and O in the flame chain. The main components of Pyrogen aerosol, potassium carbonates, are formed in the gaseous phase. In the flame chain they dissociate producing potassium radicals, which are very active and react with ‘chain carriers’ OH, H and O to remove them from the fire zone, thus disrupting the fire reaction.

The chemical action of potassium radicals in Pyrogen is similar to that of bromine radicals in Halons and can be schematically represented as follows:

K+OH → KOH

KOH + H → K+H2O

2. Recombination of flame propagation radicals ‘chain carriers’ OH, H and O on aerosol particle surface. Gaseous potassium carbonates condense to a liquid and then a solid form producing a large number of micron sized particles. Being so small, the particles produce a large surface area, where recombination of ‘chain carriers’ takes place as follows:

O + H → OH

H + OH → H2O

Secondarily, Pyrogen extinguishing action is achieved by lowering the fire temperature to a level below which the fire reaction can continue (thermal cooling). Several physical mechanisms contribute to this.

* Heat absorption via endothermic phase changes: K2CO3(s) → K2CO3(l) → K2CO3(g)

* Heat absorption via endothermic decomposition reaction: 2KHCO3(s) → K2CO3(s) + CO2(g) + H2O(g)

* Dilution of the fire combustion zone by the aerosol cloud (additional fuel molecules cannot participate in the combustion process): physical hydrance to flame propagation (aerosol particles slow down velocity of a flame front propagation) etc.

The extremely high surface area of the micron-sized aerosol particles increases the likelihood of radical recombination and heat absorbing reactions, thus ensuring rapid extinguishment with a small amount of agent.

Pyrogen has the lowest extinguishing concentration known among commercial available agents – flammable liquids (class B fires) are extinguished at the design factor of 100 g/m³ compared to 330 g/m³ (5%) for Halon 1301.

The high rate of aerosol discharge ensures a tremendous knockdown effect thus avoiding fire damage to assets or equipment.

Micron-size aerosol particles exhibit gas-like three-dimensional qualities that allow the agent to rapidly distribute throughout an enclosure and reach the most concealed and shielded location. Homogeneous distribution is achieved in a matter of seconds, while long suspension times all help to prevent fire re-ignition.

Applications

Pyrogen aerosol is suitable for the protection of a variety of potential fire hazards, including those involving flammable liquids, combustible solids, oils and energised electrical equipment.

For more information contact Samantha Wright, Alien Systems & Technologies, +27 (0)11 949 1157, [email protected], www.astafrica.com

| Tel: | +27 11 949 1157 |

| Email: | [email protected] |

| www: | www.astafrica.com |

| Articles: | More information and articles about Alien Systems & Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved