The main challenges involved in reprocessing heavy crude oil fractions are high viscosity, solid bodies and high temperatures. Since conventional differential pressure measurements are prone to wear and tear, the OMV refinery in the Bavarian town of Burghausen switched the measurement of its coker feed quantities to clamp-on ultrasonic technology.

Some 3,6 million tons of crude oil are processed every year by various methods. As opposed to conventional refineries, OMV’s refinery does not produce standard gasoline. Instead, it implements various processing stages to produce ethylene and propylene, which are shipped via pipeline to neighbouring plants, where they are used as raw materials for plastics. Heating oil and diesel fuel are transported to customers by road and rail and jet fuel is also supplied via a pipeline directly into the underground facilities of Munich airport. In addition, OMV supplies all of Bavaria with extra-light heating oil, diesel, lubricants, petroleum coke, liquid gas and bitumen.

Delayed coking

Like most coker plants in the world, Burghausen works according to the Foster Wheeler patented delayed coking method. The residue left over from crude oil distillation is fed through a tube furnace under pressure and at high velocity and heated to temperatures of 500°C. Due to the short length of time that the residue mixture stays in the oven, there is no significant coke formation. This takes place in a ‘delayed’ manner in downstream coke drums.

Feeding takes place via four feed lines with optimum mass distribution within the furnace zones crucial for efficient process control and for the service life of the furnace. The original measuring orifices that were installed for flow measurement meant significant maintenance costs due to the challenging, highly viscous medium with its constant load of coke particles. The thin pressure taps were constantly becoming blocked and had to be flushed out regularly. For this reason, process engineers looked for a modern, low maintenance alternative.

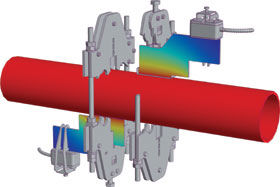

The solution was a non-invasive measurement using an ultrasonic clamp-on flowmeter system including, a high temperature transducer mounting fixture. The clamp-on ultrasonic transducers, which are attached to the outside of the pipe, are not subjected to wear and tear from the medium inside. In addition, the non-invasive acoustic method is characterised by considerably higher measuring dynamics, so that reliable measured values are achieved even during start up and shutdown, thereby making automatic control possible. Due to the high requirements for safety and plant availability, all eight measuring points were equipped with an extra ultrasonic measurement device, one in transmission mode the other in reflex mode. This ensures that operation is continuous and interruption-free and guarantees that the system is shut down once the critical minimum feed quantity is undershot.

Ultrasonic flow measurement

Clamp-on ultrasonic flow measurement systems measure according to the transit time difference method. The acoustic transducers, which are mounted onto the pipe, send and receive ultrasonic signals which are irradiated into the pipe both with and against the direction of flow. The measuring transmitter calculates the volume flow rate from the measured transit time difference and the media and pipe parameters. If process conditions are constant, the mass flow can be output directly. Otherwise, the temperature and, if necessary, the pressure at the measuring point must be recorded. Unlike differential pressure measurements, the acoustic method has extremely high measuring dynamics and is impressive both at very low volume flows and very high flow velocities due to its measuring accuracy.

However, the extreme process conditions in the coker also posed challenges for the non-invasive acoustic measurement method due to the high temperatures involved. The Curie temperature of the piezoceramics used for the transducers is approximately 300°C. Above this, the piezoceramics lose their polarisation and, in turn, the ability to vibrate by electrical stimulation. With the use of a special high temperature mounting fixture, the application range of the non-invasive ultrasonic measurement can be extended to temperatures of up to 400°C and more. Its operating principle is simple: thermal decoupling of the transducers from the pipe while acoustic contact is maintained. This is ensured by two steel coupling plates that connect the pipe and transducers. So much heat is radiated from their surface that the temperature on the fastening point for the transducers is within their working range. At the same time, the coupling plates ensure the best possible acoustic contact. The sturdy installation equipment provides continuously high contact pressure on the supporting surface, while specially adapted metal foils guarantee an optimum connection and long-term stability.

Testing and evaluation

The aim was to quantify the respective measurement accuracy of the non-invasive measurement in comparison with conventional instrumentation. For this purpose, further flow measurements at the periphery of the furnaces were taken into account. By balancing the total inflow and outlet quantities it was possible to determine the respective measurement error. This comparison clearly showed that highly dynamic clamp-on ultrasonic flow measurement allows for much better balancing of the quantities.

Accuracy is one thing, but reliability is just as important. Modern ultrasonic clamp-on measuring systems provide effective diagnostic functions which allow for reliable assessment of the quality of the flow measurements. The measuring transmitter detects the signal-to-noise ratio (SNR) as well as the signal-to-correlated noise ratio (SCNR) and shows them on the display or stores the respective values in the process control system.

Evaluation of the data indicated that the signal quality, depending on the actual process conditions, can change from excellent measurement signals to inferior signal quality and vice versa. Contrary to initial assumptions, there is no continuous degradation of signal quality due to the formation of a coke coat on the inner side of the pipe, which had often been experienced in similar applications in other refineries. At the OMV Burghausen coker unit, signal quality changes in an unpredictable manner, presumably due to varying residue oil qualities and interfering pipe wall noise with varying amplitudes and phases.

Within the first test period, a planned shutdown of the plant took place. During the shutdown, there were important changes in the composition of the fluid, temperature, pressure and viscosity. Correspondingly, the ultrasonic clamp-on flowmeter recorded significant changes in the sound velocity, from 550 m/s up to 1300 m/s. The test measurement worked well during the shutdown and subsequent start up process, therefore making it possible for the first time to monitor all important volumes and respective mass flows during all process stages.

After six months of test measurements and a further year of scrupulous evaluation, OMV Burghausen finally decided in favour of non-invasive flow measurement and subsequently removed the old orifice technology.

* According to the operators, the advantages of ultrasonic measurement are evident and convincing:

* Precise, wear-free flow measurement without measurement drift.

* Accurate quantity measurement.

* High measuring dynamics.

* Process optimisation.

* Increased operational safety due to redundancy.

* Unlimited plant availability due to non-invasive measurement method.

* Detection of entire operational range also during start up and shutdown.

* Significant reduction in maintenance costs.

© Technews Publishing (Pty) Ltd | All Rights Reserved