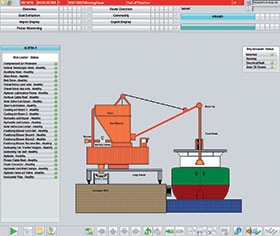

Systems Automation and Management (SAM) recently performed the automation upgrade of the Transnet Port Terminals bulk import and export facilities in Richards Bay Harbour. The port is responsible for the import and export of dry bulk ores, minerals and break bulk, with the majority of the dry bulk being handled by a network of over 100 conveyors that extends 40 km to various customers and is controlled by a PLC and scada system.

The individual conveyors, with their associated moving heads, numerous ship loaders, storage sheds and open stockpile areas with stacker/reclaimers, can combine to form over 400 possible route configurations from source to destination.

Automation challenges

The first step in the upgrade contract was a plant-wide clarification and condition report of all field I/O, followed by the compilation of a functional design specification of all the required operations.

The automation challenges were the interlocking of the conveyors and equipment on a route; starting the route in the right order; the validity of the route and the controlled stopping scenarios. All of this had to be achieved whilst keeping track of the type and grade of product that has been transported on any particular conveyor, in order to eliminate product contamination.

The existing PLC system was over 15 years old, spares were difficult to obtain and the system did not allow for any expiation and only limited modifications. This hampered expansion of the port with more functions needing to be performed manually. In addition, the port also started experiencing more automation-related outages due to the unreliability of the old equipment.

The existing system had two hot standby S5 PLCs in the main control room with four PLCs in the main substations communicating with each other via a redundant H1 network. The existing scada system communicated via a slow RS-232 link to the two H PLCs.

Since the port handles a large portion of South Africa’s mineral imports and exports it was crucial to keep interruptions and downtime to a minimum. This was very successfully achieved with the installation of a Siemens S7 with WinCC system. The terminal in fact exceeded production targets during the months when the main substations and PLC was upgraded.

During the swap out from the existing to the new system, the short plant outages, most of them only 24 hours, had to be coordinated with mining houses, export agents, shipping schedules and road and rail freight.

System replacement

The first step in the replacement of the system was the scada interface with an Ethernet module to speed up communications, thereby reducing the likely risk of that particular card failing and also providing additional access to the old and new systems. Thereafter, the team replaced the old S5 control cards with new X5/X7 controller cards, supplied by SAM, to provide the Ethernet communication between the PLCs in the four substations. Additional Profibus communication capabilities are provided to the new S7 I/O cards.

The system provides test capabilities, with the ability to run the new S7 PLC code within the S5 system. In the largest portion of the contract, the S5 I/O was removed and new S7 I/O cards were installed in the 15 substations over 36-hour shutdowns, approximately once a month. After all the I/O was migrated to the new I/O, SAM performed a thin slice test with the new code on a small section of the plant to prove the software and routing engine, then switched the plant over from the X5 control cards to the S7 400 controllers.

The new system has redundancy at all levels including hot swap-over scada servers; emergency control room with operator clients; S7 400 H PLCs; scada and plant Ethernet network; fibre optic ring configuration; Profibus network; back-up UPSs and generators for the system to continue running without incoming power; 120% spare capacity on installed I/O with hot swap capability .

For more information contact Poovan Govender, Systems Automation and Management, +27 (0)31 700 6171, [email protected], www.sam.co.za

| Tel: | +27 11 803 0570 |

| Email: | [email protected] |

| www: | www.sam.co.za |

| Articles: | More information and articles about SAM Systems Automation & Management |

© Technews Publishing (Pty) Ltd | All Rights Reserved