Sedin Engineering is China’s largest technology supplier to the coal industry. When a crushed coal pressurised gasification reactor needed to be designed for Henan Yima Coal, the company decided to explore a new avenue. Sedin worked in partnership with Siemens to develop the entire plant, harnessing intelligent manufacturing principles by adopting an ‘Integrated Engineering to Integrated Operation’ approach. In the long term, Sedin plans to optimise the plant concepts still further to improve operational efficiency and product quality for the customer in cooperation with Siemens and its solutions for the process industry – including a digital twin of the planned facility. Benefits for the customer include trouble-free commissioning and simplified plant management.

The smart, economical manufacture of customised products has long since become standard practice in the discrete manufacturing sector. Due to the complexity of the continuous processes, flexible production has proven more of a challenge in the process industries. However, when tasked with the design of a crushed-coal pressurised gasification reactor for Henan as part of a complete factory redevelopment project, Sedin was not willing to settle for a standard solution. Sedin chose Siemens as its partner to develop the digitalisation solution for the factory, aiming to increase its efficiency, to reduce cost and to achieve the best possible environmental balance.

End-to-end design boosts efficiency

As part of its cooperative involvement in developing the Henan factory, Siemens supplied its Comos engineering software, the Walkinside virtual reality platform and the Simatic PCS 7 process control system. Added to these were the Simit process simulation system and XHQ, the operational intelligence software for the processing and display of production data. Using Comos, Sedin was able to integrate the engineering process data, resulting in an end-to-end factory design. The level of detail and amount of data Comos provided allowed Sedin to increase design efficiency by 20 percent. The bidirectional data exchange between Comos and PCS 7 ensures that the design data and automation system always remain consistent. One of the benefits is that engineers are able to use the design data directly for engineering the corresponding process control solution, eliminating the need for manual data handling. This approach helped reduce system configur-ation time by around 25%. Data exchange between the systems also simplifies maintenance.

Realistic simulation

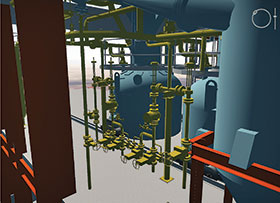

Using the simulation software Simit, Sedin created a virtual twin of the plant. This simplified processes such as commissioning of the actual plant, as it enabled Sedin to perform a virtual commissioning process and to identify and work around potential faults beforehand. Simit also supports operator training, as it can be used for workshops before and during commissioning. With the Comos Walkinside virtual reality platform, a 3D model of the plant is also made available which allows users to move around virtually and practice various scenarios such as emergency drills.

Big plans

Using the Siemens XHQ solution, Sedin is able to track the status of different gasifiers and to monitor and optimise their performance from any location. The platform permits smart plant operation by aggregating, reviewing and analysing data from a range of different sources. XHQ provides plant operators with a solid base of data on plant status, allowing plant managers to make rapid, real-time decisions – for instance on how to maximise possible optimisation potential.

Zhang Qinggeng, the general manager of Sedin, is delighted with the results of the partnership to date: “Our goal is to help our customers further increase engineering and operation efficiency, reduce operation costs, and improve product quality. Forging a strategic cooperation with Siemens is the first step we have taken towards achieving those objectives.”

For more information contact Jennifer Naidoo, Siemens Digital Factory and Process Industries and Drives, +27 (0)11 652 2795, [email protected], www.siemens.co.za

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved