In many transmission grids, the proportion of electricity from renewable energy sources is increasing. Unlike conventional synchronous generator-based power plants, wind energy and photovoltaic plants feed their energy into the grid via an inverter; however, stability problems occur above a certain proportion of inverter-based operating resources when using conventional grid-following inverter controls. Therefore, innovative control methods are needed so that the integration of renewable generation systems does not have to be restricted as a result.

Grid emulation

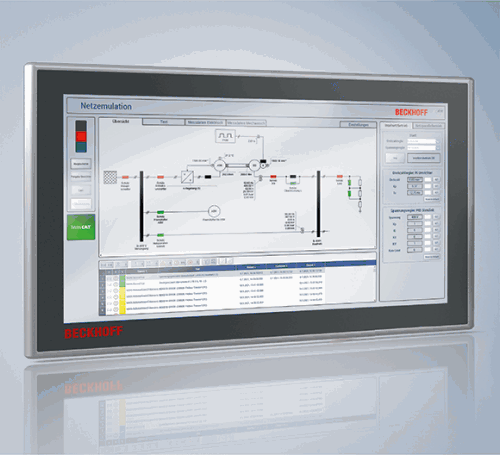

The investigation of the inverter behaviour at a strongly changing grid frequency is not possible in the European interconnected grid. For this reason, a grid emulation was built at the Institute of Electrical Energy Systems and High Voltage Technology (IEH) at the Karlsruhe Institute of Technology (KIT) in Germany, for the realistic behaviour of large power plants and therefore also for that of large transmission grids. This grid emulation consists of a synchronous generator with an excitation machine, which is driven by a variable-speed drive system comprising a drive inverter and an asynchronous machine rather than a turbine. To achieve a moment of inertia comparable to that of a turbine in a power plant, there is also a flywheel on the shaft. Frequency dips can be generated by connecting loads, as these occur during disturbances in large transmission grids. By physically providing the instantaneous reserve, the grid emulation (in contrast to power electronic grid emulations) allows an instantaneous reaction of the resources connected in the island grid to the grid frequency.

A CX5140 embedded PC from Beckhoff serves as the central automation and control hardware, while various EtherCAT Terminals are used to measure mechanical and electrical variables. Encoders are installed in both machines to measure the rotary speed and these are evaluated by EL5021 SinCos encoder interfaces. Torques can be established by means of two torque measuring shafts and an ELM300x analog voltage measuring terminal. EL3783 power monitoring oversampling terminals, in combination with current transformers, capture the 3-phase voltage, current and power values. The PC communicates with the drive inverter via EtherCAT.

Inverter emulation

The investigation of newly devised control methods for inverter-based generation plants calls for a flexible test facility that offers sufficient freedom about how control methods are implemented. Since the first step focuses on the control of the grid side of the inverter, the behaviour of the modulation and the power semiconductors of a 3-phase inverter can be emulated by three linear voltage amplifiers. The voltage amplifiers act here as controlled ideal voltage sources. The control cabinet for the inverter emulation is located between the voltage amplifier and the island grid of the grid emulation. In addition to the control hardware, other items installed in this cabinet include the adjustable mains filter, voltage and current measurements, as well as contactors and circuit breakers.

Test environment

With the inverter emulation being used in combination with the grid emulation, an island-like test environment is now available where the behaviour of new grid-forming control methods can be easily investigated. Investigations with the ‘Synchronverter’ control method, which emulates the behaviour of a synchronous generator with an inverter, have already been carried out and published. Experiments have shown that inverter-based generation systems with an appropriate control system can provide instantaneous reserve and thus support the grid. In contrast to real-time emulators, it was also possible to prove here that grid-forming control can be implemented on a control platform that is already established for use in industrial environments.

Going forward, the development of grid-forming control methods will be continued with the aim of using them in inverter-based operating equipment, such as wind turbines. Since the investigation based on inverter emulation was successful, a test bed that represents the drive train of a wind turbine, consisting of a generator and full inverter in downscaled performance, is in the process of being set up. Here, the focus will be on the use of components used in wind turbines, such as control hardware and power semiconductors. Investigations will continue into how the implementation of a grid-forming control system in a wind turbine is possible.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved