One of the things I enjoy most in my working life is optimising base layer control loops in plants in the chemical, petro-chemical and paper industries. There are several reasons for this, but chiefly because:

1. The control strategies are generally well tried and designed by engineers who usually have a good understanding of the process, the control requirements and of control itself.

2. Plants in these industries usually do not ‘skimp’ on control equipment, but use good makes of transmitters, valves and usually DCS control systems, therefore there is a good chance that control loops will work properly if set up correctly.

3. There are usually plenty of control loops to work on.

4. One can, and usually does, experience all sorts of interesting problems and challenges, most of which can be solved.

5. The plants usually run for long periods without stoppages, so lots of optimisation work can be done without interruption.

Many other industries particularly in the mining field have controls that are often really bad, with cheap control equipment, poor control strategies, and often very little interest by senior management in the control side. They also generally use PLC/scada systems which are without doubt inferior for feedback control as compared with DCS systems.

There is one particular chemical plant where I am regularly called in to help with sorting out their problem loops, and it is there that I see many very interesting things. On a recent visit to this plant we encountered enough problems to keep me stocked with material for these articles for quite a long time. Here are a few examples:

Valve with strange characteristics

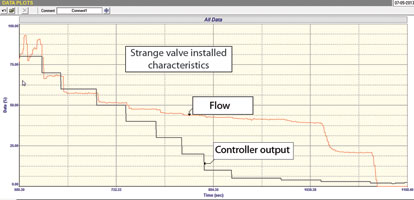

A pressure control loop was not controlling well. It did not seem to respond to set-point changes, or to changes on the PD (controller output) when in manual. Fortunately there was a flow transmitter in series with the pressure control valve, so we could do tests to determine how the valve was performing.

A section of the open loop test performed on this valve is shown in Figure 1. Basically the valve at 4% opening allowed the flow to go straight up to about 38%. From there to a valve opening of nearly 43% the flow did not change, and from there on it increased in a non-linear fashion until full flow was reached. It also appeared as if the positioner was unstable at higher flows.

I have never seen anything like this before. We did a physical check on the valve to ascertain if it was following the PD signal properly, and it seemed to be doing this fine. The only possible reason that I can think of that could be causing this strange characteristic is that the valve had been supplied with some weird inherent characteristic.

The plant is waiting for a shutdown to open it up and inspect it.

Interactive loops required proper tuning strategy

Most of my articles do not discuss tuning very much, but tend to concentrate on problems that need to be sorted out or taken into account before tuning can be undertaken, if indeed it is at all possible, as in the case of the valve in the previous example. However, tuning is obviously also very important.

Very few people really have any idea on how to tune properly and the vast majority of loops are tuned very badly, most of them being too slow to react properly to changes.

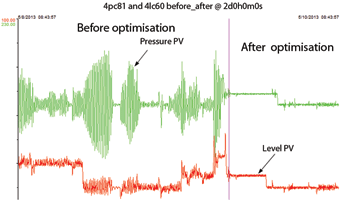

During my work at the plant, a senior process engineer asked that we try and sort out two important interactive loops that were fighting each other badly and disrupting production.

It is beyond the scope of this article to go into too much detail on this, but basically all you can do to try and ‘decouple’ interactive loops by tuning, is to tune the one as fast as possible, and detune (slow down) the other one until they no longer fight each other. (Operators good at decoupling interactive loops, they just put the one in manual and problem solved.)

In any event in this case there was a pressure loop fighting a level. The problem was solved by tuning each of them properly. Figure 2 is taken from the plant’s trends showing the operation of the two controls before and after optimisation. The people in the plant were extremely pleased with the vastly improved performance.

Improved tuning of an important temperature control

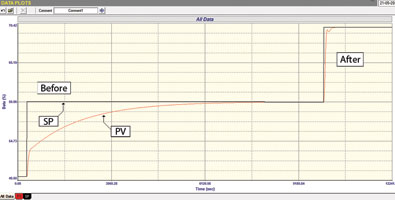

Temperature controls are often very badly tuned. One of the major reasons for this is because they often have excessively slow responses to changes. One famous control expert recently wrote in an article that temperature control loops are usually the worst tuned of any processes, as the average human being has not got a long enough life span to tune them properly if they use ‘trial and error’ instead of a good tuning package.

The example given here is of a steam desuperheater temperature control. The original tuning was P = 1, I = 10 minutes/repeat and the process took over 2 hours to get to set-point after a 10% change.

The Protuner tuning gave P = 3, I = 1 minutes/repeat. The response now, for the same change of set-point, took only 10 minutes – an almost unbelievable improvement. Figure 3 shows the difference in the ‘before’ and ‘after’ responses. This is a wonderful example of how badly many temperature control loops are tuned. The expert is absolutely correct. You definitely need to use a good tuning package for such difficult slow processes.

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering, +27(0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved