Over the past five decades, the company has continuously adapted to market demands, technological progress and client expectations. Its initial focus on the fast supply of components soon grew into a more comprehensive offering. Its inventory has grown in both breadth and depth, and now includes a wide array of hydraulic and pneumatic components to meet diverse applications.

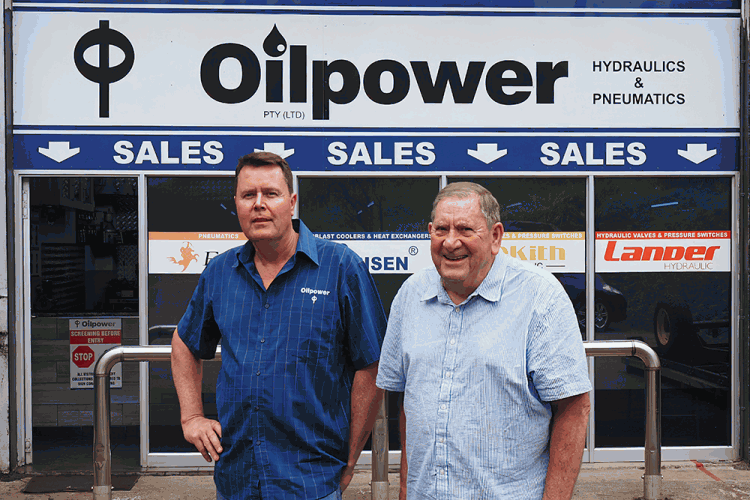

Oilpower operates from a well-equipped branch in New Germany, which serves as both its headquarters and a central operations hub. This location enables the company to support clients throughout KwaZulu-Natal and the wider southern African region. With a dedicated team of 22 staff members, including highly skilled technicians, Oilpower provides expert consultations, hands-on services, and efficient system integration. For over fifty years, the company has embraced the motto “THE CUSTOMER IS KING.” Additionally, Oilpower maintains a comprehensive inventory of hydraulic and pneumatic components, including pumps, motors, valves, cylinders, filters, and accumulators, among others.

Its pneumatic product range includes mould cylinders, quick couplers, pipes and fittings. The business is not tied to a single brand, which allows it flexibility in sourcing both common and hard-to-find components. This, together with its repair and manufacturing capability, allows Oilpower to respond swiftly and effectively to client needs, whether it’s a customised system or a fast turnaround on a critical replacement. Oilpower’s experience covers a number of industries. These include agriculture, where the team provides support for equipment like tractors, cane grabs and balers; construction and earthmoving, with solutions for hydraulic attachments; and pneumatic components and mould cylinders for the plastics industry. All these industries depend on durable, high-performance fluid power systems, something Oilpower has specialised in for over 50 years. In addition to supplying parts, Oilpower offers complete system integration and consulting services. These include dedicated hydraulic and pneumatic design, pipework installation, valve configuration and bespoke power unit manufacture. The company often delivers turnkey systems for agricultural and plastics manufacturing clients, ranging from the design phase through to commissioning and after-sales support. A recent example would be the complete design and manufacture of commercial sawdust baling machines for the poultry industry. Oilpower also manufactures pipe wrapping machines for corrosion prevention and industrial log splitters, as well as high-quality slashers for the agriculture sector, to name a few.

Maintenance is another important pillar of Oilpower’s offering. The company provides both scheduled maintenance and responsive repair services for hydraulic and pneumatic systems. Whether it’s a leaking cylinder, a failing valve or a full system assessment, Oilpower’s team can assist on site or at their workshop to ensure minimal downtime and maximum equipment life. Services such as precision machining or specialised fabrication are outsourced to trusted local partners. This allows the company to be flexible while offering the depth of knowledge and quality expected by its clients.

While most of Oilpower’s operations are in South Africa, particularly in KwaZulu-Natal, the company has supported projects abroad. Its vision going forward is to expand its geographic footprint even further across the region.

Oilpower’s success is based on a clear strategy to deliver innovative, reliable and tailored solutions that address real-world industrial challenges. This is achieved through strong client relationships, deep technical expertise and a culture of continuous improvement.

With a proud legacy and ambitious plans ahead, Oilpower is set to continue its contribution to southern Africa’s fluid power industry.

For more information contact Cheryl Mackinnon, Oilpower,

| Tel: | +27 31 705 9871 |

| Email: | [email protected] |

| www: | www.oilpower.co.za |

| Articles: | More information and articles about Oilpower |

© Technews Publishing (Pty) Ltd | All Rights Reserved