Virtually all feedback control courses worldwide are presented theoretically. This is understandable, feedback control theory was largely developed back in the early 1900s by some of the world’s leading mathematicians, including Bode, Nyquist and the father of PID, Nichols. However, mostly mathematicians do not come from planet Earth but from the extraordinary planet Mathematica where the denizens speak the strange language of Mathematics, extremely difficult for ordinary mortals to understand.

The result is that the vast majority of control people arrive in a plant after graduating to find that apart from a few very individuals, no one involved in practical control uses any mathematics. This is because there are no practical mathematical models of the process transfer functions that take real-world imperfections into account. So, people cannot use the things they have learnt at school and they resort to learning to ‘fly by the seat of their pants’ and follow the path of PID ‘knob twiddling’ in the hope that this will solve the control problems.

This is borne out by a study undertaken by a control journalist some years ago in the USA. He investigated tuning methods in over 135 plants in both North America and Canada, and reported that he found that 98% of all tuning was done in plants by using either the WAG or SWAG methods. This is his definition of those methods: WAG = Wild A*se Guess and SWAG = Scientific Wild A*se Guess.

Another common definition of tuning methods is ‘Trial and Error’, which in the case of a leading South African paper plant turned into ‘Trial and Horror’.

Basically what happens is that people play around with the controls and over the years start developing their own ideas and feelings about optimisation. I find that many of these ideas are completely wrong. In discussions on a professional control social network, I frequently come across contributions by people who are supposed to be experts on the subject. Many of these are obviously based on empirical know-how and are completely wrong. Also, when giving courses, I find that many of the more experienced practitioners of control initially find difficulty in accepting the things I teach as they go against the concepts they have accepted for years.

The more common misconceptions

Some of the topics that people have the wrong ideas about include:

1. When, and how to use the D (derivative) term in the PID controller. There is more misunderstanding about this than virtually any other control topic.

2. Understanding how to set-up the PID controller in a PLC properly. Typically they are not working correctly in 85% of plants I work in. In several cases, they are not working at all and the people on site not even aware of it.

3. Understanding how controllers work and what the various options are designed for. This can cost plants huge amounts, £14 million per annum in under-production at one pharmaceutical plant in the UK.

4. How to analyse, tune and troubleshoot PID controllers scientifically.

5. The belief that all control problems can be solved by tuning. In reality tuning is the very last procedure that should be performed when optimising control loops.

6. The belief that all tuning should be set for quarter amplitude (sometimes called quarter wave damping) response to set-point step changes. This is taught in many theoretical control courses, but in reality it is not good for practical reasons. Amongst other things it means that the control valve goes through approximately eight reversals every time the controller tries to correct an error, which is ridiculous. It is also not robust enough for real life control. (In reality, I find about 85% of all control loops are tuned anything from 20 to 1000 times slower than quarter wave response, because very few people know how to tune loops in practice.)

7. Understanding the differences between self-regulating (eg, flow control) and integrating (level control) processes. They behave differently and must be tuned differently.

8. The belief by process engineers that it can all be handled by the C&I people. In fact, it is almost essential that they too should have an excellent understanding of control as they have the process knowledge and should be able to guide the C&I people as to the purpose of the control and how it should operate. They should also understand the limitations of feedback control.

9. Many plants, particularly in the mining industry, are designed by process specialists who have no knowledge of, or interest in, control. The controls appear to be added as an afterthought. As a result control strategies are sometimes incorrect and cannot work properly. Typical examples of this in the mining extraction business are sumps with insufficient retention times to smooth out surges and flotation tank lines without an upstream surge tank to ensure a constant flow of product in the line.

10. The belief that if a loop cycles it must be due to bad tuning. In fact there are at least eight different things apart from tuning that can cause cycling in a loop.

The people who are generally the most excited after completing our courses on practical control are C&I specialists with years of experience. They usually finish the courses wishing that they had acquired that knowledge years ago. The second group are process engineers and specialists. One chemical engineer (who had graduated with a first in control) said to me at the end of a course that she had had no idea previously of the intricacies of practical process control. She stated that she would push for all the process managers, engineers, and specialists in the company to attend the course, because now she realised how important it was for them to have that knowledge.

How it works in the real world

As an illustrative example of the problems I have been writing about, I will use another example of a loop in a continuous cycle which was not caused by bad tuning. (Case History 118 dealt with several others.)

The loop in question was a level control where the requirement was to keep the level on set-point and to deal with load upsets as quickly as possible. The problem being experienced in the plant was that the loop was always cycling, and, of course, everyone had been trying for years to tune and stabilise it.

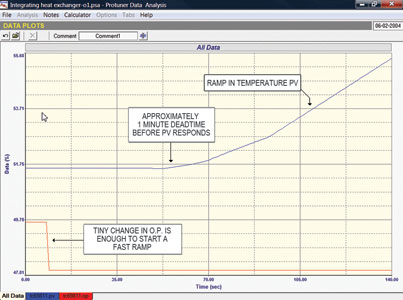

Figure 1 shows the open loop test. There are two things of interest: firstly there is a dead-time of about a minute before the level starts responding to a change in the output of the controller. This is really excessive and we were not able to find out what was causing it. (Normally one would expect to encounter a dead-time of a few seconds maximum on such a process.) This makes the process very difficult to control, as dead-time means that one must slow the controller down to try and avoid instability. Secondly, a small change on the output caused the level to change very quickly as the tank had a very small retention time. This means relatively large process gain and makes it difficult to control.

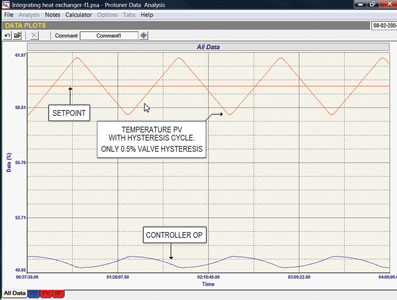

Both excessive dead-time and large process gain mean that the controller has to be tuned slow to avoid instability, thus only a very low gain can be used. However, even with a slow tune the loop still continued to cycle. One of the first things people are taught in our practical optimisation course is that if one has hysteresis on the valve in an integrating process, and if you are using P+I control, then a continuous cycle WILL result.

Figure 2 shows the closed loop test with the oscillation. It is a classic case of an integrating loop hysteresis cycle! The cycle was probably being intensified because of the dead-time, but unfortunately short of removing the integral term from the controller, tuning cannot stop the cycling. This cannot be done here, as the low proportional gain in the controller would result in large offsets from set-point. The only things that can be done are to fix the valve and possibly investigate why the dead-time is excessive. Much better and faster control could be obtained if the dead-time was reduced.

This is a good example of how important it is to understand the practicalities of control not discussed in theoretical courses where everything is assumed to be perfect. Unfortunately, we do not live in a perfect world – particularly when it comes to process control.

Michael Brown is a specialist in control loop optimisation, with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa, and also to other countries. He can be contacted at Michael Brown Control Engineering, +27(0)11 486 0567, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved