In the previous Case History article 124, I promised to show some more interesting things taken from the amazing ‘problem free plant’. However, before doing this I would like to show a very interesting tuning performed on the steam drier section on a paper machine.

The vagaries of positive lead integrators

The controls for the steam drying sections on a paper machine are extremely important as they regulate the amount of moisture in the paper. The moisture content is measured when the paper leaves the machine and a sophisticated advanced control system determines the set-points of the steam pressure regulatory control loops on the inlet of each drying section further back down the machine.

These controls are required to follow the set-points as quickly as possible so as to keep the control variance to an absolute minimum. The set-points are usually moving around slowly, so, if the controllers cannot keep the process variable on set-point, bad moisture control will result that can cost the plant a lot of money.

Back pressure controls on steam driers have very interesting dynamics being positive lead integrators. This was dealt with in great detail in my Loop Signature articles LSp2-20 and LSp2-21. As mentioned there, most people find them extremely difficult to tune as they can go unstable quite easily – they are usually tuned really badly and extremely slowly. This is mainly due to the fact that very few people know how to recognise the dynamics of a positive lead integrator, and those that do have not been taught how to tune them. Once tuned correctly, these loops follow set-point extremely quickly and with virtually no variance at all, as the correct tuning is in fact extremely fast and very stable.

An example in practice

In this particular case I was called in to sort out some serious control problems on the paper machine. In particular, the pressure controls were terribly bad; it could take over an hour after a paper break or a grade change to get the pressures back within acceptable limits.

It was a very interesting assignment. The paper machine was being controlled by a well known German PLC/scada system. This in itself is unusual, as generally controls on sophisticated plants like paper machines are DCS based, since these are much more versatile and refined than PLCs. As I have written many times, I generally find in at least 85% of cases that the control blocks on PLC systems are set up incorrectly making scientific tuning and correct operation impossible.

In this particular case the control blocks were programmed so badly that it was decided to rewrite and change them over as we optimised each loop. An extremely difficult and challenging operation to perform on a plant running at full load, however, we managed it without actually tripping the machine.

The first loop in the steam controls that needed to be optimised was the main supply pressure regulating control that fed all the drier sections on the machine. This is an important control the purpose of which is to keep the downstream steam pressure supply constant. If it is not tuned correctly and as fast as possible, then all the downstream drier pressure controls can interact badly.

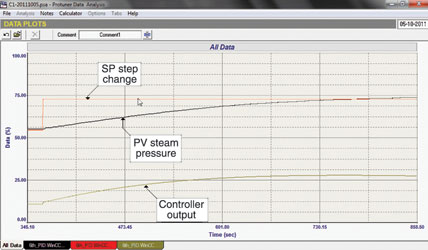

As suspected, it was found that the tuning of all the pressure controls was terrible. An example of one of the drier pressure control loops running in automatic with the original tuning is shown in Figure 1. A 10% set-point step change was made. It took over 4 minutes for the PV to get to the new set-point, which it then overshot and took roughly another 10 minutes to settle.

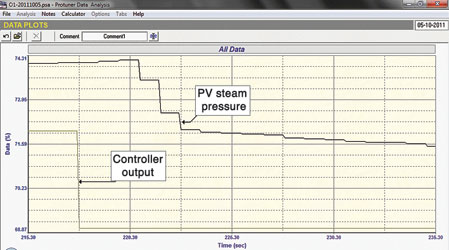

Figure 2 is the open loop test which shows the initial big and fast kick of the lead, before the pressure settles into the typical integrator ramp. Please note that the steps in the PV as seen in the recording are due to the OPC data exchange information system which we were using to record the test. Typically most OPC systems have a 1 second scan rate which explains the badly aliased signal seen in the test.

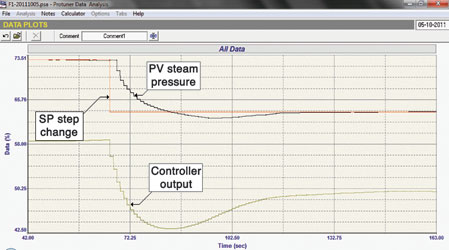

The final tuning is seen in the closed loop test in Figure 3 – it is spectacularly faster than the original. Again a 10% set-point change was made, this time the process got to set-point within 20 seconds and had completely settled a few seconds later.

We often call this dramatic tuning of positive lead integrators our ‘party trick’, because people who witness can hardly believe how quickly and accurately the PV follows subsequent set-point changes. In this case, the work on this paper machine was really successful and the plant personnel were astounded at the improvements in machine performance.

More ‘party trick’ tuning

Returning now to the previous Case History Article 124 where the bad performance of a fuel oil pressure control loop, which was the secondary cascade to the temperature control of a furnace, was discussed. I promised that the tuning of the primary cascade temperature loop would be given in the next (this) article, so here it is: the original tuning parameters on this very slow temperature process were:

P = 0,35.

I = 0,7 minutes/repeat.

D = 0,6 minutes.

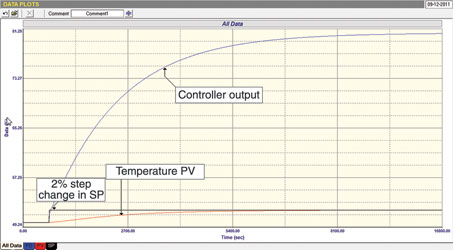

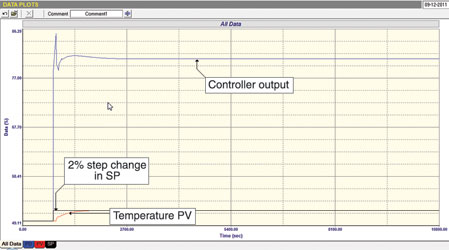

Figure 4 shows the response to a small 2% step change in set-point, it took almost 3 hours for the process to settle.

An open loop tuning test was then performed with the following new tuning parameters inserted in the controller:

P = 15,0.

I = 4,0 minutes/repeat.

D = 0 (not used).

The almost miraculous improvement in response to a 2% step change can be seen in Figure 5. It now took only 25 minutes for the process to respond and get exactly on set-point.

To be fair, even if we ignore the terribly badly tuned secondary pressure loop, it is extremely difficult for anyone to tune really slow temperature processes without the right equipment. The famous Greg McMillan, a retired senior fellow from Solutia/Monsanto where he worked in engineering technology on process control improvement, wrote an article recently where he said that it is beyond the capability of the average human being to tune a slow temperature control loop by trial and error – they do not have a long enough life span.

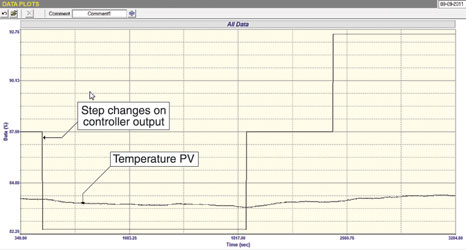

Luckily I use the Protuner loop analytical and tuning software, which does all the maths and hard tuning calculation work for you. The actual open loop test from which the tuning was done is shown in Figure 6. The test took approximately 1 hour to complete and there are a couple of extremely interesting points:

Due to the extreme importance of this control and the effect it can have on downstream units, the operators would only allow us to move the temperature by 2°C, which is equivalent to 0,4% of the temperature span! That really is tuning on an almost imperceptible change, so it is incredible what good results were obtained by the software – almost miraculous!

Note the large size of the change of PD (controller output) compared with the small size of change in the PV (temperature) in the figure. Calculating the process gain (PV/PD) we get a figure of 0,065. This is absolutely tiny for a self-regulating process, where for example on flow loops it is normally between 0,5 and 2,0. This alone means that one has to use a very high controller proportional gain to compensate. (Refer Loop Signature article LSp1-3 for a detailed discussion on process gain).

I believe this tuning also falls into the ‘party trick’ category.

Note: Michael Brown’s next practical control course series starts on 17 August in Johannesburg.

Michael Brown is a specialist in control loop optimisation, with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa, and also to other countries. He can be contacted at Michael Brown Control Engineering cc, +27(0)11 486 0567, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved