When SKF South Africa was approached by a key customer to assist with a bearing and housing selection for a ball mill that is being produced for a site in North West Africa, the bearing and rotating technology specialist delivered a complete cost-effective solution within the required time frame.

The customer, who specialises in grinding mills and comminution processes, has over the past three years been employing several SKF product and service solutions, including bearings and housing assemblies for mill pinion applications.

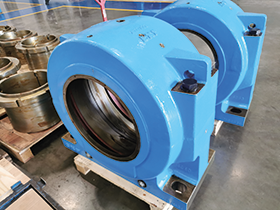

The holistic solution from SKF consists of spherical roller bearings (23292 CAK/C3W33), locally designed and manufactured custom housings (CSD 231-500), adaptor sleeves, an oil taconite sealing arrangement, and locally manufactured adaptor sleeves (OH 3292 H). The customer also called for a life calculation on a specific pinion design.

According to SKF application engineering manager, Janus Bezuidenhout, the 23292 CAK/C3W33 was selected as the best possible bearing, based on the pinion criteria that they received from the customer. SKF assisted with the bearing selection via various SKF software programs.

The local bearing housing, which was selected based on past successful projects with a similar footprint, is based on the South African designed SDJD-type housing. As this housing is specially prepared for circulating oil lubrication, it is perfectly suited for the 23292 CAK/C3W33 bearing. Bezuidenhout explains that these specifically designed housings are custom for both the customer and the application. “The customer required a housing that is durable during heavy loaded applications, while at the same time custom designed to ensure that it fits the end user’s structure and takes into account the pinion centre height. Moreover, the material we selected is suitable for occasional high vibrations, temperature differences and loading specifications.

“The added value offered by these particular bearings and housings is that they both have good lead times in terms of availability, ensuring on-time delivery of the project and in accordance with the customer’s requirements,” shares Bezuidenhout. He also draws attention to the units’ price competitiveness. “Local manufacture eliminates the need for import and associated costs around exchange rates, enabling us to remain within the customer’s budget.

“Another benefit of this particular type of housing design is that SKF can modify the sealing arrangements and housing bore to suit the required bearings and seals,” adds Bezuidenhout. “The locally designed and manufactured oil taconite sealing arrangement we used has been implemented in the industry for many years and is custom for large size bearings operating with circulating oil lubrication.” It consists of a static ring that is mounted on the housing; a flinger, clamping and spacer ring that is used to secure all the components on the shaft and matches the static ring; and a V-ring that is incorporated with a grease port in the static ring. The V-ring prevents contamination from entering externally into the bearing and the grease port is used to purge the contaminates out of the sealing arrangement. O-rings are incorporated to seal the arrangement on the shaft and prevent contamination from entering the bearing.

Bearing maintenance is facilitated by the adaptor sleeves, which make mounting and dismounting of the taper bore bearings on parallel bore shafts easy. Bezuidenhout explains that the taper of the sleeve corresponds to the taper of the bearing and there are oil injection ports for the mounting and dismounting procedures. The locking nut and clip for locking the bearing in place is inclusive of the sleeve.

“SKF’s involvement in the complete supply chain solution, from procurement to delivery, put us in control of the entire process, enabling us to mitigate any potential risks around the project,” states Bezuidenhout.

SKF delivered all the components within the required lead time in March 2023 to the customer’s storage yard, from where they were transported via sea freight to the final end user in North West Africa. “The success of the project prompted the same customer to request us to replicate the solution for another project in West Africa, which we again delivered on time in April 2023,” concludes Bezuidenhout.

| Tel: | +27 11 821 3500 |

| Email: | [email protected] |

| www: | www.skf.co.za |

| Articles: | More information and articles about SKF South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved