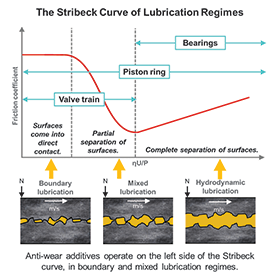

Anti-wear additives are used to protect against wear and the loss of metal surfaces during mixed-film and boundary-film lubrication. This group of additives is often referred to as boundary lubrication additives. These polar additives are usually triggered by temperature or elevated loads at the contact surfaces, and work to form a protective film to minimise wear. Anti-wear additives are among the most commonly utilised additive packages, and generally come in the form of either anti-wear (AW) or extreme-pressure (EP) additives.

Although the terms anti-wear and extreme-pressure additives are often used interchangeably in the language of lubrication, there are notable differences between their chemistries and the way they function.

In general, AW additives are designed to deposit surface films under normal operating conditions and reduce the rate of continuous wear. EP additive films are formed by reacting rapidly with a surface under severe stress to prevent more extreme modes of failures. In general, AW additives are used for low-load and high-speed conditions, while EP additives are used for applications that have high loads and low speeds.

Contact occurs in conditions of mixed and boundary lubrication, and they are activated by the heat of contact to form a film that minimises wear. Anti-wear additives are enlisted to combat wear in engine oils, hydraulic oils, automatic transmission oils, gear oils, greases and many other applications. They are often phosphorus-based polar compounds with oil-soluble tails and polar heads that have an affinity for metal surfaces. These polar heads physically bond, or adsorb, to the metal frictional surfaces (like iron to a magnet) to form a protective film.

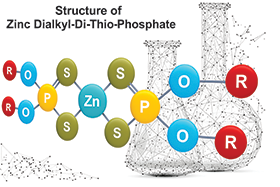

Zinc dithiophosphate (ZDP) compounds are the most commonly used anti-wear additives. Among these, zinc dialkyl-dithiophosphate (ZDDP) − a specific subset of ZDPs characterised by having dialkyl groups − is the most prevalent form used in lubricants. With an estimated global market size of $2,62 billion in 2023, it’s fair to say that ZDDP is a lubricant formulator’s best friend.

This additive also functions as a secondary antioxidant or peroxide decomposer. The history of ZDDP is a story of accidental success. Intended as an antioxidant, their unique strength as anti-wear agents was discovered serendipitously in the early 1940s.

ZDDP made its world debut as a lubricant additive in 1941, when three different companies − Lubrizol, American Cyanimid, and Union Oil − filed patents with claims of corrosion- and oxidation-inhibitors in engine oils.

However, the anti-wear properties of ZDDP remained mostly unnoticed until the advent of V8 engines with overhead valves and increased compression ratios, like the legendary Oldsmobile Rocket and Cadillac OHV in 1949. Like many early high-performance V8 engines of this era, these roaring beauties suffered from serious cam and follower wear due to the increased stresses placed on the valve train, but when oils containing ZDDP were used in these engines, less wear was observed than those oils without it, and the connection was made. As a result, the automobile industry quickly adopted the use of ZDDP as an anti-wear additive in engine oils.

While the lubricant industry at the time recognised ZDDP’s effectiveness as an anti-wear additive, the detailed mechanisms of how it worked were not fully understood. As analytical techniques became more sophisticated, researchers were able to study the chemical interactions between ZDDP and metal surfaces, but it was really only in the 1990s that researchers gained deeper molecular insight into the specific chemical reactions involved.

They discovered that ZDDP decomposes to form a glassy, phosphate-based tribofilm on the metal surfaces. This film is primarily composed of zinc polyphosphates, but can also incorporate iron from the metal surfaces it protects. These polyphosphates create a glassy or amorphous film about 50 to 150 nanometres thick and self-regulate to stay at that thickness.

The tribofilm also exhibits intelligent behaviour by becoming stronger and more resilient as the load increases, which is particularly beneficial during engine startup when mechanical stress is highest, and adequate lubrication may not yet be fully established.

This adaptive response ensures that the film provides enhanced protection precisely when it is most needed, and for this reason, ZDDP has been a mainstay of lubricant formulation and performance for more than 80 years and with good reason: no single additive provides the same benefit as cost effectively.

Unfortunately, ZDDPs play havoc on modern emission-control devices like catalytic converters and diesel particulate filters (DPFs). The operation of catalytic converters like diesel oxidation catalysts (DOC) is altered by the phosphorous present in engine oils that contain ZDDP. The phosphorus can partially volatilise during engine operation and, once in the exhaust stream, it can reduce the efficiency and deactivate these catalysts by coating and building up on the active catalyst sites, causing irreversible damage that accumulates over time.

As a result, increased levels of harmful emissions like nitrogen oxides, carbon monoxide and hydrocarbons pass through these catalysts unchanged and into the atmosphere. Catalyst poisoning by phosphorous can also significantly decrease filtration efficiency of DPFs, which also results in reduced soot-regeneration activity.

The sulphur component of ZDDP can also inhibit the effectiveness of Selective Catalytic Reduction (SCR) systems by poisoning these catalysts, which can increase the conversion of sulphur oxides to sulphates, which in turn increases particulate emissions and accumulation of particulate material. It gets worse, because the zinc component of ZDDP contributes to the formation of ash when the oil is burned, and this ash accumulates in the DPF, increasing back-pressure and reducing the efficiency of the filter.

To mitigate these effects, the industry is moving towards low-sulphated ash, phosphorus and sulphur oils and alternative additive chemistry to provide the necessary anti-wear protection without compromising the efficiency of emission-control systems.

| Tel: | +27 31 700 5460 |

| Email: | [email protected] |

| www: | www.wearcheck.co.za |

| Articles: | More information and articles about Wearcheck |

© Technews Publishing (Pty) Ltd | All Rights Reserved