As part of its extensive work to help develop benchmarking standards for wire rope lubrication in South Africa, lubrication specialists, Lubrication Engineers (LE) South Africa, has found the Viper wire rope lubricator to be a key element for effective lubrication application and rope maintenance.

Designed and manufactured in Australia over 15 years ago, the Viper was initially developed for port ropes, but LE South Africa saw its immense potential for different types of wire rope applications and has led the introduction of the Viper into the local market. “It really shines in in the mining sector, particularly for six-stranded triangular mine winder ropes,” says Ronald Byrnes, LE’s business development manager.

Byrnes has helped to drive the formalisation of LE’s Xtend team – a group of lubrication technicians who are highly skilled in assessing, applying and monitoring lubrication systems for wire ropes. Part of the Xtend team’s focus has been establishing benchmarking standards for wire rope lubrication in South Africa. “The Viper has been a key part of this process, and we see a major difference in the impact of lubricants when the Viper is used for application,” says Byrnes.

Another major win for maintenance teams is the time saving that the Viper offers. When machines using wire ropes come to a standstill in order for lubricants to be applied, a plant loses valuable time. “Where it would take several people several hours of scrubbing a rope to clean it, which can leave a machine like a winder rim or a shaft closed for more than a day, with Viper products, teams can clean and lubricate in a single pass within an hour,” explains Byrnes. “It takes us very little time to set up and it can run continuously; even changing pails of lubricants is done in real time.”

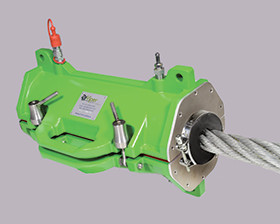

The Viper consists of two collars that are hinged. It is fitted internally with seals made from a polymer composite with ridges inside. It is a compressed air driven system that pushes the lubricant into the rope using approximately five bar of pressure. “The ridges inside it massage the lubricant into the rope, particularly the outer strands and the valleys between the outer strands of the rope, so that one gets a proper specified coating coverage of the rope,” says Byrnes.

With other methods of lubrication application, the lubricant can actually become both a contributor to and part of the formation of rust and degradation of the rope. “With ropes where we applied lubricant using the Viper, I haven’t had any instances of rust on ropes,” says Byrnes.

Safety, cost and environmental benefits

Environmental impact and safety are also critical aspects of rope lubrication. Bitumen-based lubricants, when exposed to the high temperatures required in order for them to be applied, release toxic fumes that pose significant health risks. Maintenance teams also face risk in having to handle the molten bitumen-based products. In contrast, the types of lubricants that are used with the Viper system eliminate these risks. Products, such as LE’s Wirelife Almasol Coating Grease 452, are suitable for the Viper system and improve overall site safety, says Byrnes.

In addition to the safety benefits, investing in a Viper for wire ropes has long-term return on investment gains for companies. “For clients, success to date has also been measured on the return of investment over the long term through preservation and better use of maintenance expenditure,” explains Burns. “Although it requires capital to purchase a Viper system, once it is in place, it quickly balances out in maintenance cost savings.”

For more information contact Gavin Ford, Lubrication Engineers,

© Technews Publishing (Pty) Ltd | All Rights Reserved