A wastewater treatment plant (WWTP) in the Western Cape is undergoing a R1,7 billion upgrade. Currently treating 72 Ml/day, the new plant will be more reliable and efficient, with a further 18 Ml/day of additional capacity. Sales manager Willem Strydom highlights SEW-EURODRIVE’s contribution to the project.

The Western Cape’s WWTPs are being upgraded as part of a broader global initiative to fight pollution in the world’s oceans. The 26 plants involved were built back in the 1950s and 60s and are in dire need of modernisation. The plants are all to be expanded and rehabilitated as part of a €2 billion investment in the province’s water infrastructure.

“At one of the largest of these plants, a mostly brand new modern waterworks is being constructed that not only prevents routine overflows of untreated sewage into the sea, but is more modern, energy-efficient and reliable,” says Strydom.

He continues that the company’s product portfolio of industrial gear units has been widely specified for use by several of the contractors on the project, but its direct role is for the supply of 20 units for each of the new aeration tanks on the plant.

He explains that aeration is the fourth stage of the treatment process. The first stage involves bar screening, which removes large pieces of debris and solid objects. A further screening stage then removes finer solids before the water is passed into primary clarifiers, which remove both inorganic solids floating on top of the water and those that settle to the bottom of the tank. The wastewater, which now contains mostly fine organic matter, is then passed through a bank of aeration tanks, where oxygen and activated sludge combine to ‘consume’ the organic contaminants in the water, converting them into carbon dioxide and water.

Once the water has passed through a series of aerators, it looks as clear as drinking water, but it still contains fine suspended solids, so the water is passed into a secondary clarifier. Coagulants are added to bind the particles, which then settle leaving relatively pure water at the top of the tank. From there, the water goes through stage six for chlorination and disinfection and after testing and analysis it can be safely discharged or recycled.

“For the aeration drives for this WWTP upgrade, we were approached by one of our local treatment plant OEMs back in 2018. Through this OEM, we are supplying 20 units and while these are not complete turnkey solutions, we are assembling them as pre-engineered drives with the gearboxes, motors and couplings mounted onto custom-designed baseplates, so that once onsite it is very easy to couple each drive to the aeration impeller,” he adds.

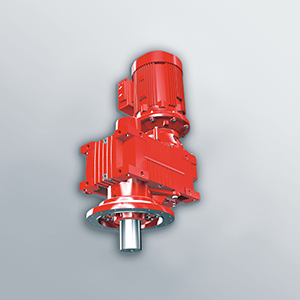

At the heart of the 20 aeration units the company is suppling is its MC Series range of parallel shaft industrial gear units, which have been specifically designed for aeration and mixing applications. “Of the 20 units, 10 are 75 kW units, four are 55 kW and the remaining six are 90 kW drives,” he says.

A key feature of these MC units is their extended bearing distance (EBD), which is purpose-designed for shaft loading from agitating, mixing and aerating applications, which transfer very high axial and radial loads back into the gearbox. EBD helps to stiffen the shaft to resist these loads, significantly reducing the radial movements seen by the seals, bearings and gears, resulting in better reliability, less wear and longer life.

Other key features include:

• An especially compact parallel shaft design.

• A one-piece, robust mono block, which enables horizontal, vertical and upright assembly.

• An optional Drywell seal, which reliably prevents oil leakage from the output shaft.

• Easy customisation with the range’s modular concept for achieving optimal gear ratios.

• Additional optional equipment such as motor adapters, belt drives and backstops.

“Following the scare in Western Cape in 2018, when cities in the region were just 90 days away from turning off the taps, municipalities in all provinces are now looking to modernise their wastewater infrastructure. We are currently involved in several new opportunities. As well as restoring our water quality and security, water infrastructure projects have a lot to offer the South African economy, most notably investments – and these projects are happening,” Strydom concludes.

| Tel: | +27 11 248 7000 |

| Email: | [email protected] |

| www: | www.sew-eurodrive.co.za |

| Articles: | More information and articles about SEW-EURODRIVE |

© Technews Publishing (Pty) Ltd | All Rights Reserved