In this issue Michael Brown has forwarded an interesting article submitted by Melvin Jones who graduated from the University of Pretoria as a chemical engineer. He has a keen interest in process control and optimisation, and is currently completing a Master's Degree in chemical process control. In his professional capacity he is a process engineer on an ammonium nitrate production facility, concentrating his efforts on improving the controllability of the prilling section.

Concentration control for inferential measurement

At an ammonium nitrate prilling plant the control of the concentration of a side stream, for use in inferential measurement, is of critical importance. By making use of the Protuner environment, the team were able to decrease the inherent lag in the system by more than 50%, as well as tighten the control of the system significantly. All this was achieved in spite of the inherent difficulties created by the rapid solidification of ammonium nitrate at static control points. The techniques applied in solving these problems can easily be applied to other control loops, making the learning a valuable tool in the control engineer's arsenal.

In the production of porous prill using the TOPAN technology, the tight control of reaction parameters is critically important. One of these reaction parameters is the pH. The problem is that the highly corrosive nature of the reaction solution makes the direct measurement of the pH impossible. In order to measure the pH, a diluted solution is maintained at 50%, and the measurement is used to infer the pH of the corrosive solution. The concentration of the diluted mixture is controlled using only temperature measurement, and tight control of the concentration of the diluted solution is critical - due to several control problems this proved difficult.

The temperature of the reaction mixture, as well as the water, is measured. These readings are used to calculate the required temperature of the mixture to maintain a 50% concentration. The temperature of the diluted mixture is controlled using the flow of reaction mixture, while the cold water flow remains wild. Since the variation in reaction mixture concentration is relatively small, the final temperature gives a good indication of the concentration of the mixture.

The system, as explained above, has historically been difficult to control. In August of 2001 the plant purchased a Protuner control loop analytical and tuning package. The step testing and system models generated improved the understanding of the system. Changes were then made to the physical system to improve the controllability of the system as a whole.

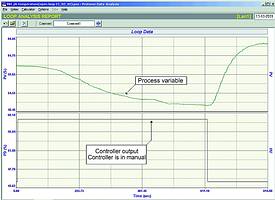

Figure 1 shows the recording made of the original system response. Only two steps are shown to highlight the response of the system, one in the positive direction and one in the negative direction.

Note that the valve is reverse acting, with a decrease in valve position corresponding to an increase in the ANS flow. Also note the very different settling times between an increase and a decrease in the settling time.

When the system was first evaluated for response times, the time to steady state for a positive change (in valve position) was roughly 600 s, while a negative change settled in less than 200 s. While these settling times are in themselves not very long, the total retention time in the mixing vessel is less than 10 s.

By making use of the controller settings suggested by the above loop recording, very poor control was achieved. It is thought that due to the nature of ANS, ie very likely to fudge and solidify, a slow acting valve was likely to suffer from a gradual build up of product around the outlet of the valve. In order to attempt to prevent this, the gain on the controller was dramatically increased, creating a situation where the valve bounces around, preventing fudging. While this improved the control, the variation around the setpoint was still unacceptably high.

Again referring to Figure 1, one notices that the system lag is at least 20 times greater than the inherent system hold-up. This suggests that there is an additional lag that is not obvious in the system that is creating a sluggish response. Using this information, it was found that the temperature probe on the final mixture was inserted in a thermal well. This additional temperature lag could account for the system's additional lag.

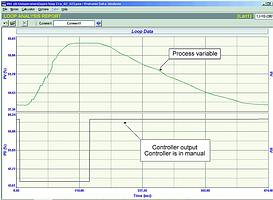

Figure 2 shows the system response after the thermal well had been removed. In this figure, one can see that the positive step has stabilised in roughly 70 s, while the negative step stabilises in 250 s. Thus in both cases the lag duration has been more than halved. Using these results, the loop becomes much more responsive, but still does not behave as it should. Once again, it is suspected that the solidification around the valve outlet, due to insufficient valve movement could be the main contributing factor.

Finally, in order to 'destabilise' the loop slightly, derivative control was added. This is not uncommon for temperature control loops, and served to add the valve movement required to prevent solidification. Thus, by making use of the broad range of tools available, it was possible to dramatically tighten the control of this loop.

Comparing Figures 1 and 2, one notices that in both instances the loops are not symmetrical to an increase and a decrease in the valve position. While at first glance this may appear strange, it is an entirely expected phenomenon. Since the process has the capability to add energy, ie via a very hot stream, but only a limited capability to remove energy, ie via heat loss and the wild stream, the system responds much quicker to a positive change than to a negative one. This does complicate the tuning, since one needs to tune either for a positive or a negative scenario. Usually one would do both, and then tune for some compromise between the two, thereby ensuring the tightest possible control.

Conclusions

By making use of the Protuner software, valuable information beyond simple controller settings can be obtained. Since the software provides a clear formal environment to evaluate the responses of a control loop, one can often detect faults in both the physical set-up and the controller logic.

On the prilling plant it was possible to tighten the control of a critical loop considerably, by determining the following factors using the software:

* The response of the loop was slower than expected. The time to steady state of the system was an order of magnitude larger than the inherent lag in the system, suggesting an additional source of thermal lag.

* The response of the system was non-linear. While this situation cannot be addressed using the current system, it does provide valuable information into the final determination of the controller settings.

* The nature of the product handled resulted in loss of flow should the valve remain stationary for extended periods. By introducing a known variability/instability it was possible to improve the control of the system.

From the above discussion it is clear that by combining the tuning capabilities with the friendly evaluation environment it is possible to make considerable improvements to a control loop. It is also clear that while the software delivers powerful results, the correct application significantly improves its usefulness.

The Loop Signature series of articles on digital controllers will return again in the May issue, with the last article discussing the D term.

Michael Brown Control Engineering

011 486 0567

A note and an invitation from Michael Brown:

I have been writing these articles for this magazine on a monthly basis for over six years, and although I really enjoy sharing my experience and knowledge with SA I&C's readers it sometimes gets quite difficult to try and produce articles that have something of new interest in them. I am therefore inviting readers to send me suitable articles for publication of interesting experiences they may have encountered themselves whilst optimising processes, or in finding solutions to their own control problems.

Michael Brown is a specialist in control loop optimisation, with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses that can be held in clients' plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa, and also to other countries.

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved