Integrators and automation specialists require powerful dispensing solutions that can be flexibly adapted to a wide range of project requirements and integrated using the plug-and-produce solution. The Scheugenpflug ProcessModule and the DispensingCell DC803 were developed with these requirements in mind. The focus was on simple integration into a wide range of system designs and flexible data connection, a high level of dispensing quality when processing a variety of materials, short cycle times, and comprehensive process monitoring. All in all, the solutions of the Scheugenpflug product line from Atlas Copco are the result of more than 30 years of expertise in dispensing technology with advanced control technology. PC-based control from Beckhoff has been in use here since 2012. According to the Scheugenpflug experts, this PC- and EtherCAT-based control and drive technology offers an open system, fine scalability and a broad product range that individually meets demanding customer requirements.

The central element is the axis system

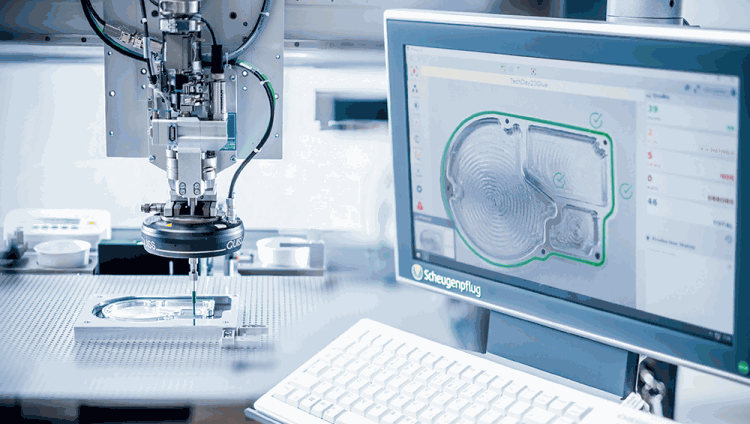

The Scheugenpflug axis system is quick and easy to integrate reliably into new or existing production lines or production cells using a plug-and-produce solution. All parameters and processes relevant to bonding and potting are perfectly coordinated – independently of the rest of the machine. With its powerful axis and servo technology, the ProcessModule also offers high travel speeds and short cycle times in matrix, bead and fill potting.

The ProcessModule is also used in the Scheugenpflug DispensingCell DC803 multifunctional cell. This offers the necessary flexibility to implement the increasingly demanding and individual requirements for bonding, sealing and potting processes for medium (40 000 to 200 000) to high (200 000 to 2 million) quantities. The cell is specially designed for series production with short cycle times, particularly in the automotive, industrial electronics and medical technology sectors. In addition to the flexible application options and the integrated additional processes, e.g., for process monitoring, it boasts a high axial load capacity, and intuitive operation and programming of the dispensing processes.

Sophisticated CNC-controlled dispensing functions

The DC803 is implemented for a number of extensive automation tasks. These include open-loop and closed-loop control of the dispensing head, the high-speed gantry system with interpolated movements, product handling and the inspection processes. The necessary computing power is provided by the ultra-compact Industrial PC C6030 which, according to the Scheugenpflug experts, was chosen primarily for its compact design as well as its high and easily scalable computing power. A CP3916 stainless steel multi-touch Control Panel connected via the CP-Link 4 one cable solution acts as the interface, providing the machine operator with a stable and robust operating concept with a long service life. For this customer-specific version, the company opted for branding with a centrally placed company logo and selected a keyboard and mouse tray for ergonomic operation. Beckhoff TwinCAT offers an open and secure architecture, and by using the Automation Device Service from Beckhoff, all required data can be sent to Scheugenpflug’s own visualisation system.

The highly precise movements that are essential for demanding dispensing applications are calculated centrally in TwinCAT CNC on the industrial PC and executed with the servo drive technology, namely for the X-, Y- and Z-axes of the ProcessModule, for the spindle axis of the dispensing head, and for optional additional rotary axes. From Scheugenpflug’s point of view, the Beckhoff servo technology – which includes two AX5203 servo drives and AM8000 servomotors – offers the advantage of free and integrated configuration options using interfaces and excellent scalability with additional transformation options.

In addition, it is quick, easy and compact to install due to One Cable Technology (OCT). With its functions for safely reduced speed and a safe stop, TwinSAFE ensures safe system operation. This is implemented using the AX5805 TwinSAFE option card in the servo drive and with the EL6900 and EL1904 EtherCAT Terminals or the EP1908 EtherCAT Box as additional TwinSAFE components.

The Scheugenpflug experts agree that the company benefits from the broad Beckhoff portfolio of EtherCAT I/O components with IP20 and IP67 protection ratings. It enables flexible I/O use both in the control cabinet as well as in decentralised installation directly on the machine, with fast and space-saving wiring as a result. It also provides the necessary system openness to integrate PROFIBUS, PROFINET, and EtherNet/IP components seamlessly into the EtherCAT network with its high performance and comprehensive diagnostic options, and to flexibly integrate the multifunctional cell into larger systems.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved