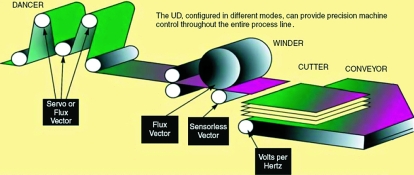

The Berges UD 7000 from Elquip Solutions includes operational modes for general purpose volts-per-hertz (V/Hz) operation, speed or torque control with sensorless vector, flux vector and brushless AC servo.

Application-specific software such as an electronic gearbox with positioning for supervisory drive systems, master/follower, crane control, dancing arm control and tension winder applications are standard.

The drive allows for easy installation into existing applications with a compact, metal IP20 enclosure. Special packaging in Nema 4/12 cabinets is available. Options include stainless steel remote keypad station, resolver and encoder boards for flux vector and servo modes, PC software tool, Profibus modules and heavy-duty IP54 dynamic braking resistors.

There is a 2-line x 16-character LCD alphanumeric display for easy access to parameters, simple operation, and user-friendly display of faults and programming. Two languages (English, and German) are available as standard with other languages available as an option. When multiple UD 7000s are installed, regardless of operational mode, operators and technicians deal with common controls simplifying installation, operation, and service.

Pre-configured application modes simplify installation; and the Berges UD 7000 comes pre-configured for frequently-used applications such as: dancing arm controllers, process controls, open-loop tension control, master/follower and electronic gearbox controls.

The key features of the UD 7000 are the brushless servo operation; flux vector control; sensorless vector and general purpose V/Hz:

Brushless servo operation

A servo mode is incorporated for high dynamic speed or torque-regulated applications with feedback from an encoder or resolver. The UD 7000, teamed with a brushless servo motor, provides impressive dynamic response. Since the motor is made with rare earth magnets, users enjoy low inertia and high power density. The synchronous motor has no-slip and accurate speed control. Applications would include: Positioning, machine tools, injection moulding, direct drive punch presses, storage and retrieval.

Flux vector control

As a high-performance, closed loop vector inverter, the UD 7000 is suitably matched with a vector duty motor with encoder enabling full torque at zero speed. The torque control capability makes the UD 7000 appropriate for use in difficult applications such as crane and hoist operations or tension control in web processes. Application-specific software is standard to meet a wide range of applications. To further simplify installation and operation, the UD 7000 automatically tunes itself to the no-load motor parameters and does it without turning the motor shaft.

For maximum flexibility, the unit includes an electronic gearbox for master/follower operation with positioning. A servo mode is incorporated for high dynamic speed or torque-regulated applications with feedback from an encoder or resolver. The UD 7000, teamed with a brushless servo motor, provides good dynamic response. Applications would include: cranes and hoists, machine tools - drilling and tapping, tension control.

Sensorless vector

An advanced sensorless vector algorithm provides superior control for a variety of applications. The UD 7000 regulates the speed of an AC induction motor with high precision through fast calculations of measured data and auto-tuned parameters. The algorithm uses advanced sensing circuitry believed to result in less speed drift than other available sensorless vector controls. This further adds to precise control and operation. Suitable applications would include: Extruders, screw conveyors, positive displacement pumps, wood working machinery, centrifuges and mixers.

General purpose V/Hz

The UD 7000 can handle the simplest to the most complex applications. In the V/Hz mode, it provides all the control necessary for basic installations and allows advanced operational flexibility for future upgrades or easy retrofit into existing systems. It can also supply selectable carrier frequencies to minimise irritating audible motor noise. Applications for this mode would include conveyors, centrifugal pumps, blowers, fans, high speed spindles.

About Elquip Solutions

Elquip Solutions is owned and managed by Mike Cronin, who founded the company in 1999. The business was formed as an electrical distributor of locally sourced products. As Elquip Solutions grew, it found a niche market in the tube and pipe industry.

From there the company grew its products base and sourced capital equipment for the tube and pipe industry and has since developed into a leading international distributor of electrical, automation and mechanical products.

Elquip Solutions concentrates on sourcing and delivering high quality products, systems and solutions. Its primary objective is the importing and distribution of, amongst other items, electrical and automation products, capital equipment for tubes and pipes, consumables.

The Berges UD 7000s different modes of operation make it suitable for many different applications.

For more information contact Mike Cronin, MD, Elquip Solutions, 011 826 7117, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved