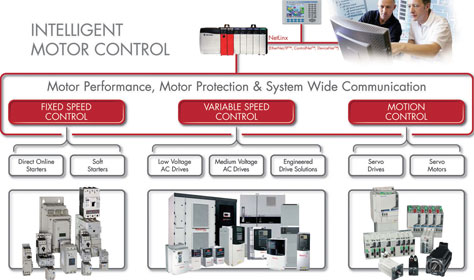

Intelligent motor control solutions from Rockwell Automation protect investment, help optimise productivity and improve uptime. In fact, intelligent motor control is an integral part of an automation system.

Seamless integration into architecture

Today, manufacturers still face significant integration challenges when designing systems that use different control disciplines, systems and software. Bridging the gap between the platforms can increase training costs, decrease productivity, lessen connectivity and reduce the ability to customise.

This is where intelligent motor control from Rockwell Automation offers a distinct motor control advantage. By combining the advanced, system-wide communication capabilities of integrated architecture with intelligent motor control devices, users can implement a single solution plant-wide that helps control, communicate and protect assets.

Premier integration helps to seamlessly and cost-effectively integrate control, visualisation and information technologies. This allows re-use of engineering designs and practices to decrease development time and cost, respond quicker to market demands and reduce maintenance and downtime.

Premier integration is a key feature of intelligent motor control. It is integrated drive configuration in the Rockwell Software RSLogix 5000 that allows users of Allen-Bradley PowerFlex drives to consolidate drive system configuration, operation and maintenance into a single, integrated environment. This helps to reduce programming, installation and overall ownership costs by minimising the number of software tools required.

Bridging safety and productivity goals

High production volumes and the use of multiple automation systems in a single plant can make identifying and eliminating potential hazards a complex task. This means manufacturers must be diligent in their training practices and highly selective in their technology choices to increase workplace safety. The good news is that intelligent motor control is making this easier with an expanded array of solutions designed to deliver enhanced safety, greater productivity and cost-saving advantages.

From Motor Control Centres with ArcShield options to help protect from arch flash incidents, to the new safe-speed control functionality to safely monitor and control the speed of a motor in the PowerFlex 750 series of drives, customers benefit from flexible, easy-to-implement and easy-to-use solutions, designed to help make their facilities safer, leaner and more productive.

Better decision making

All industries are re-evaluating standard business operating procedures in an effort to uncover additional savings. With an estimated 60% of maintenance, repair and operations inventory typically classified as excessive or inactive, implementing a strategic asset management approach, especially with motor related assets, can uncover savings while improving return on net assets and overall equipment effectiveness metrics.

As part of the intelligent motor control portfolio, networked motor control systems and condition-based monitoring provide vital motor performance diagnostics, enabling users to perform maintenance before costly damage and related downtime can occur to motors or connected equipment. This data driven information gives manufacturers the ability to competitively meet both product quality and product development goals.

Driving sustainability and efficient operation

With electric motors as the driving force behind most production output, improved motor control performance and motor efficiency mean greater overall production efficiency. The technology behind intelligent motor control – including variable frequency drives, intelligent software and networked motor condition monitoring devices – is capable of providing both an immediate and measurable impact on energy use and operational efficiency.

The final piece for success

With a broad range of control to fit virtually any motor control requirement from across the line starting, soft starters and drives, to packaged power solutions and motion control, intelligent motor control should be an integral part of the process – it is the piece of the puzzle that helps make it all come together. With it, you can better protect your plant investments, gain tighter control, make programming easier and boost data driven reliability in your motor driven applications – equating to an increased return on investment and real bottom line savings.

Automation University

Rockwell Automation presents companies with the opportunity to learn more about leading edge automation solutions and experience the company’s products at its biennial event, Automation University. To find out more about the intelligent motor control system, attend this year’s Automation University on 18 and 19 August at Emperors Palace – e-mail Michelle Heydenrich at [email protected]

For more information contact Adrian van Wyk, Rockwell Automation, +27 (0)11 654 9700, [email protected], www.rockwellautomation.co.za

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved