This is the third article taken from a report which was prepared for various departments in a process company after some optimisation work was performed for them. (The other two articles were published in previous issues).

The first example in this article is of a success story. Production was complaining that the control of a critical temperature in a certain process was extremely poor. It was vital to keep the temperature as close to set-point as possible under varying load conditions, and as the control was not successful at doing this, production results were poor.

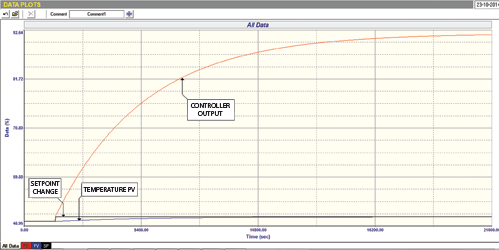

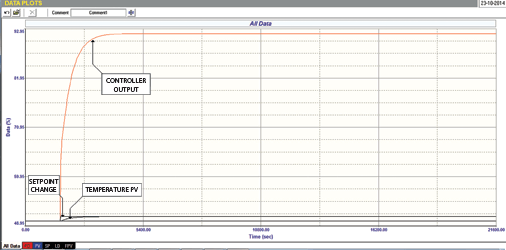

Closed and open loop analytical tests showed that there were no problems in the loop, and that the valve was performing well. However, the tuning was unbelievably slow. Figure 1 shows the closed loop test with the original tuning. A tiny (1%) set-point change (2°C in this case) was all that production would allow us to make. It took an unbelievable 5½ hours for the control to get the process to move this small amount. The response with decent tuning is shown in Figure 2. The time taken to move the temperature the same amount was dramatically reduced to 45 minutes!

The original tuning was P = 1.0, and I = 1.5 minutes/repeat. The final tuning was P = 12.0, and I = 2.0 minutes/repeat.

(As in the previous article, the figures shown here are done by an accurate simulation since it is much easier to see details that are obscured in the original graphs.)

The second example in this article is of a major problem with the control of combustion airflow to a furnace. The operators were trying (without much success) to run the control in manual, as it was impossible to get any sort of control in automatic.

The plant technicians had tried to get the control to work by tuning the controller terribly slowly, so that it did not jump around too much. This, I find, seems to be a common approach by many people who haven’t been taught the mechanics of practical process control. This comes from the widespread belief in many plants that any loop problem can be solved by tuning. So, if a control is jumping around or cycling, then people slow down the tuning until the process looks stable. Now, of course, every operator knows that (s)he can stop cycling and jumpy control by putting the controller into manual. I refer to manual control as the “ultimate slow tuning”. Thus in many, if not all cases, if you slow the tuning of a controller down sufficiently, the process stays stable, and the control looks good. However, the controls are there to deal with set-point and load changes. So in reality, most of these detuned loops are useless as they cannot respond quickly enough to such changes.

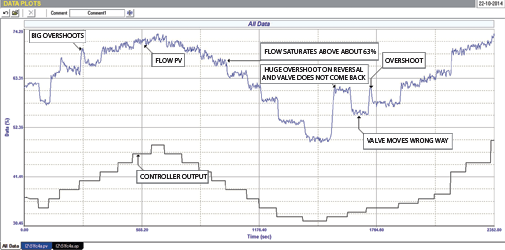

Anyway, in this case, the open loop test immediately revealed the real problem, which was a control damper that desperately needed maintenance, if not replacement.

Figure 3 shows this test with the controller in manual, and with a series of steps, mostly of equal size, being made in both directions on the controller output. It can be clearly seen that the damper displayed serious problems that would preclude it from being able to allow any sort of automatic control.

Amongst these problems are:

1. The damper overshoots badly on opening.

2. On reversals it sometimes overshot very badly, and at other times stuck, and did not get back to the correct position.

3. On one occasion in the test it was seen that on increasing controller output, the damper actually moved in the wrong direction.

These problems effectively result in the damper being non-repeatable, and if your final control element does not do what the controller asks it to, then you can forget trying to control with it.

Another problem seen is that the flow saturates at about 60% of range when the controller output reaches 40%. This could be a process problem or incorrect loop design. In any case it would be good to investigate this, as operators often tend to try and get the flow into regions above the saturation point, and other problems can occur from this.

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering, +27 (0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved