The first part of a report, published in Case History 140 (February), showed successes obtained and problems uncovered in an optimisation exercise in a particular process plant that takes optimisation very seriously. The plant has benefited both financially and from a productivity point of view, by ensuring that their base layer controls are running properly. As mentioned, this report was circulated to other relevant departments including C&I maintenance, process engineers and management.

Example 1 – proper tuning solves the problem

The first example in this second article is of a success story. Production was complaining that the control of a level in a particular drum was extremely poor. Tight level control is needed and it is vital that the level stay as closely as possible to setpoint under conditions of frequent load changes.

The figures shown here are done by an accurate simulation, as it is much easier to see what is happening than by looking at the original graphs, which were very noisy.

The level control consists of a normal flow-level cascade. The flow control was working well, and the problem was found to be with the tuning. Levels are generally integrating type processes, which are difficult to tune if one doesn’t understand how they work, particularly on long retention time vessels, which is the case with this particular process.

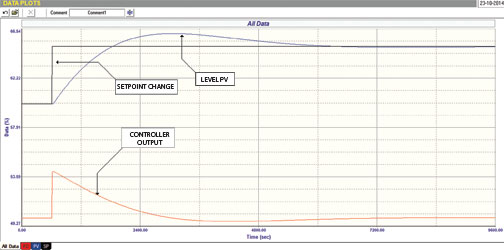

Figure 1 shows the response to a 5% step change in setpoint. The original tuning was P = 0,8, and I = 24,5 minutes/repeat. It can be seen that it took the level nearly 2 hours to move the 5% and get the PV to the new setpoint! One can see why the operators were complaining of bad control performance. There is no way this control could effectively catch load disturbances.

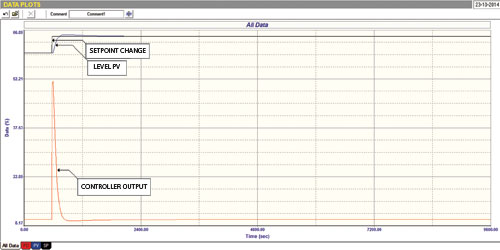

The controller was retuned to P = 8,0, and I = 11,0 minutes/repeat. The response to a 5% setpoint change is shown in Figure 2. The response time to move the 5% is now only about 15 minutes, some 8 times faster. This type of performance can be critical in effective production of complex processes.

Example 2 – non-linearity and poor design make for an impossible situation

The second example in this article is of a major problem with the temperature control of the desuperheater on a boiler. This is a critical control as it controls the temperature of the steam, and can affect all sorts of processes in the plant that use the steam, particularly in distillation processes. The actual control is the secondary of a temperature to temperature cascade on the desuperheater. This is the control that actually operates the spray water cooling valve.

Strangely enough, even though there was a flowmeter measuring the flow of water through the valve, this was not cascaded to this temperature control which is the sensible thing to do.

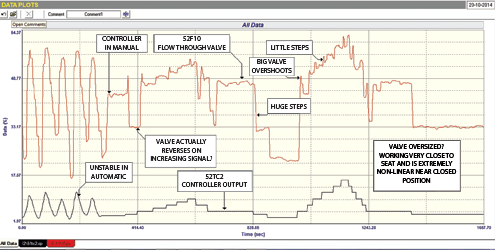

The control was not working well and was running in manual, causing much aggravation and difficulty for the operators, let alone the effects on production. Figure 3 shows an open loop test which was performed by making step changes on the output of the controller, and observing the valve response by recording the flow through the valve.

The test shows that the valve is really bad with respect to the following:

• It appears to be hugely oversized and controller output is working very low down which suggests the valve is almost closed. There is tremendous non-linearity in this region causing instability in automatic.

• The valve is sticky, and it sometimes moves the wrong way and it also has large overshoots on stepping.

There is no way that good control can be achieved with this valve. The valve should be used in cascade flow control to the temperature controller – this will go a long way towards solving the problem.

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering cc, +27 (0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved