There is a particular continuous process plant in South Africa that takes base layer control loop optimisation extremely seriously. (Many other plants unfortunately do not, which to me is terribly sad.) I do a lot of work for that plant and spend several weeks every year with a team of their advanced control engineers working on analysing and optimising loops that have been identified as not working well and causing problems.

A new approach

In the past, my reports have been passed on to other relevant departments including C&I maintenance, process engineers and management. Due to the fact that people in these other departments have little understanding of practical control, the reports have often not been properly understood or the problems fully appreciated. On my last visit, it was decided firstly that selected personnel from the other departments would attend the optimisation work relevant to their plant sections, and secondly, that the reports should now be fully illustrated, with respect to how we analysed the problems, and presented at a meeting to heads of the other departments. In addition to this, selected personnel from these other departments will also attend my courses on practical control, which are very different from most other courses on control, and give a really good understanding of what happens in real life in control loops.

We have decided for at least the interim period to publish these reports in parts in this series of articles in SA Instrumentation and Control. Previously we have tried to put quite a lot of detail into the articles resulting for reasons of space requirements in the figures being relatively small. These articles will each show only one or two of the items in the report.

The reports not only contain problems, but also successes that highlight the improvements that can be obtained by a control loop that is working and responding properly. Some of these successes of extremely slow loops have been illustrated by accurate simulations, as it would have taken an extremely long time to do recordings of both the original and final performance.

Real world example

This particular article will show one such success, but with a relatively small problem.

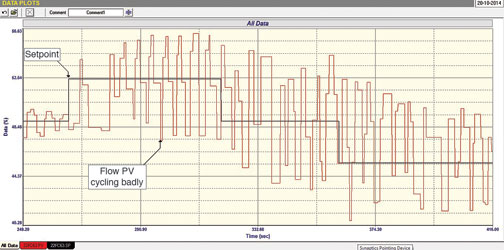

Figure 1 shows the as ‘As Found’ closed loop test on this flow loop which the operators were complaining about as being ‘very jumpy’. The test shows the loop running in automatic with the original tuning and responding to several step set-point changes. It can be seen that the loop was in fact completely unstable.

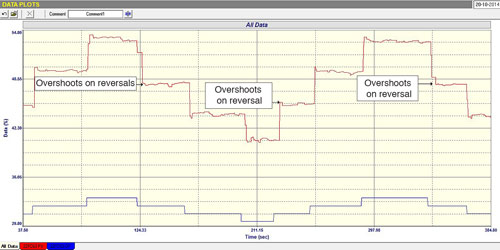

Figure 2 is an open loop test and shows firstly that the valve is suffering from negative hysteresis which causes it to overshoot when its direction is reversed. This can result in instability in automatic and is caused by either an underpowered actuator or a positioner problem. Secondly, the test shows that the valve is about four times oversized. This is determined by the magnitude of the changes of the PV compared to those in the change of PD (controller output). (Oversized valves increase control variance and amplitude of cycling by the oversize factor.)

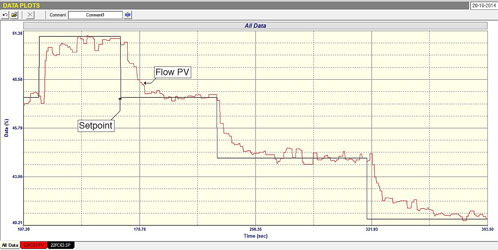

It was decided to tune the controller using the step responses shown in Figure 2. Surprisingly enough given the valve problems, the relatively good control shown in Figure 3 was obtained. There is still a small amplitude sporadic cycle occurring, which will only be eliminated when the cause of the negative hysteresis is determined and eradicated. The main cause of the original massive cycling was due to bad tuning.

The next article will feature more from this report.

Michael Brown’s next course series in Johannesburg will take place on 20 February.

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering cc, +27 (0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved