I have written much in the past about the peculiar problems inherent to integrating processes. The most commonly found of these are level controls, but some pressure control loops, particularly those with compressible fluids like steam and gas, are often also integrating.

Problems associated with integrating processes

Integrating processes are inherently unstable and can easily run away. Controlling them in manual can be tiring on operators, making onerous demands on their time, so they really need to run in automatic. Unfortunately very few people have been taught to understand the characteristics of integrating processes, and often have no real idea on how to tune them.

Integrating processes running in automatic are often cycling with periods that can be really long. The two most probable reasons for the cycling are:

* Bad tuning.

* An integrating process that has hysteresis on the valve and that has been tuned with P+I parameters on the controller will always cycle continuously.

A practical case

The example here is of a critical pressure control loop on a distillation column that was cycling continuously. This interacted with other controls on the same column and also caused cycling on other downstream columns.

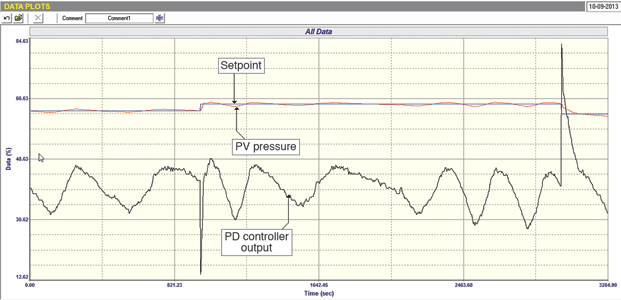

Figure 1 is the closed loop test. It shows the process in a continuous slow cycle with a period of approximately 6 minutes. Setpoint changes were made, firstly up, and then back down again. The controller is doing quite a good job, keeping the process within ±1% of setpoint, but the problem is that to achieve this, the controller is working really hard and the output is cycling with an amplitude of about 10%. This was badly affecting other downstream loops.

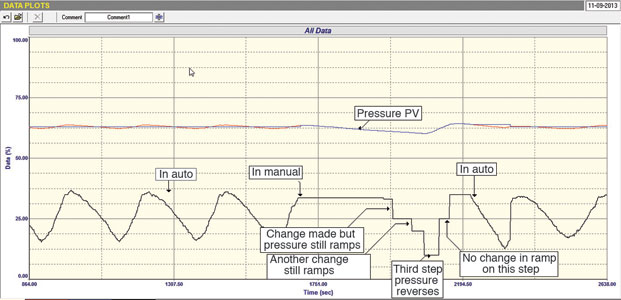

An attempt was made to stop the cycling by placing the controller in manual. To do this and keep the PV constant it is necessary for the PD (controller output) to be at the balance point, which is where the valve position is such that the output of the process is equal to the input of the process. (For example in a level control the flow into the vessel must equal the output flow from the vessel if the level is to stay constant.)

In Figure 2 it can be seen that when the controller was put into manual the pressure PV started ramping downwards. The PD was the reduced in steps to try and get the process to a balance point. However, after moving the PD down by 14% the PV ramp still remained constant which indicated that the valve was not moving, and must be sticking. A further 10% step was made, and then the PV ramp reversed and moved upwards.

The PD was then stepped upwards by 15%, but the ramp still carried out at the same rate. A further 10% step caused it to start moving the other way. The controller was then put into automatic with a P only control. This is equivalent to the control by a ball valve which always finds a balance point – normally an easy way to find the balance point. However, in this case the level kept on ramping down at a constant rate. After the PD had moved down some 27% under the action of the P term, the ramp suddenly reversed, which suggested the fact that the valve was suffering from approximately 27% hysteresis. This of course is unacceptable for a control valve which should have a maximum of 1% hysteresis.

Conclusion

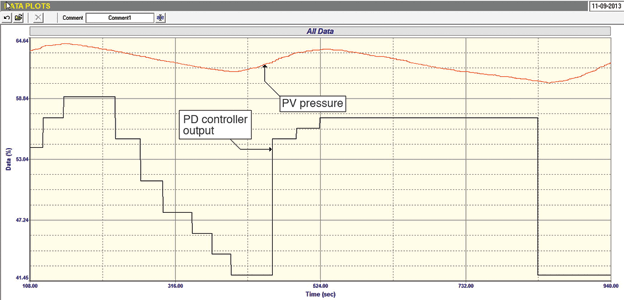

To confirm the diagnosis, and to try and determine the magnitude of the hysteresis more accurately, a second test was performed in manual (open loop). This is shown in Figure 3. This time smaller steps were made on the PD, and it was found that at least 17% hysteresis actually exists on the valve.

This explains exactly why this loop is cycling. Basically the output of the controller has to move back through 17% every time it has to reverse the valve, and the valve then jumps so that a stable balance point can never be obtained.

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering, +27(0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved