Faulty positioner causes instability

Jan 2000

System Integration & Control Systems Design

Mimic Crafts

In a recent course held in a South African chemical plant, a loop was encountered that cycled continuously. The loop was a pressure control that was acting as the slave (secondary) loop in a cascade temperature control system on an oil heater. Figure 1 is a schematic of the control system. Repeated attempts had been made by the plant over an extended period of time to tune the loop to stop the cycling.

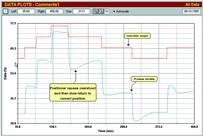

Figure 2 shows the closed loop test 'as found' performed by the class on the pressure loop. It can be seen that the loop cycled continuously with an amplitude of approximately 10% on the process variable (pressure signal). (The different changes in the test are where setpoint changes were made.)

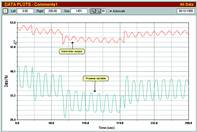

The next test performed was in manual. Equal changes of 5% were made in the output of the controller as can be seen in Figure 3. The response on the process variable is very interesting. It can be seen that on every change the pressure seemed to 'overshoot' and then after some seconds slowly ramped back until it reached stability. A response like this is invariably due to a problem associated with the positioner, and sometimes also because the actuator of the valve has insufficient power to move the valve correctly, and the positioner then pumps too much air into the actuator to try and get the valve to move. Experience has shown that this type of response often causes complete instability in automatic mode.

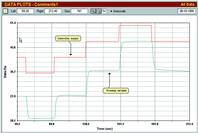

In this particular case the resident plant 'valve expert' was called and the class went into the field with him, and inspected the valve. It was found that there was a problem with the positioner's feedback cam follower which was not moving freely. This was then adjusted. Figure 4 shows the next open loop test performed after fixing the problem. Note how well the process variable follows the controller output. The loop worked extremely well after tuning it correctly and putting it back in automatic.

This was yet another example of the need to analyse a loop first, before trying to tune it.

Further reading:

Project & industry

System Integration & Control Systems Design

Project and Industry

This project involved delivering a complete electrical, instrumentation, and automation solution for a new OEM drum-twister machine, replacing an ageing unit in a major cabling production

...

Read more...

It’s a risky business not to challenge standard language

System Integration & Control Systems Design

On the surface, contracts all look alike. Once you’ve seen one, you’ve seen them all, or so it seems. Maybe so, but hidden within the standard language can be language that shifts the other party’s risk to you.

Read more...

Containerised Electrical & Control System Powers Paste Plant in Botswana

System Integration & Control Systems Design

Delivering a complete, containerized solution for a mine’s paste plant in Botswana, this project stands as a model of modern EC&I execution — integrating electrical, control, and automation systems into

...

Read more...

Control system upgrade: Smelting

SAM Systems Automation & Management

System Integration & Control Systems Design

Systems Automation & Management recently completed a major control system upgrade in the smelting industry. The project was delivered on budget and achieved a positive ROI for the client.

Read more...

Gottwald drives upgrade: Ports and harbours

Abacus Automation

System Integration & Control Systems Design

In the ports and harbours sector, Abacus Automation completed a significant modernisation of a Gottwald crane, improving both operational reliability and serviceability.

Read more...

Mining industry upgrade: From ageing systems to maximum capacity

System Integration & Control Systems Design

Iritron recently undertook a major upgrade in the mining sector, focusing on washing and screening plants, jigs, thickeners, tailings, water systems, conveyors and reclaimers.

Read more...

Agogo Integrated West Hub Project: FPSO/subsea offshore Angola

Moore Process Controls

System Integration & Control Systems Design

The Agogo Integrated West Hub project represents a historic milestone in the FPSO and subsea industry, achieving first oil offshore of Angola. This project is the first FPSO deployment since ANPG’s establishment in 2019, and the first major project for Azule Energy since 2022.

Read more...

Integrated Robotics and Control Systems Deliver 45% Production Boost at Aquazania Waters Project and Industry

Process Dynamics

System Integration & Control Systems Design

Project and Industry Process Dynamics designed and commissioned a state-of-the-art Reverse Osmosis

(RO) water purification and automated bottle filling plant for Aquazania Waters in Linbro Park, Johannesburg.

...

Read more...

Project and Industry

System Integration & Control Systems Design

The Sicomp Control System Upgrade focused on modernising a 1985 power generation control system with more than 3 000 I/O points. The plant faced increasing system failures and risk to operational continuity,

...

Read more...

Digital transformation from the edge

DirectLogic Automation

System Integration & Control Systems Design

Edge-enabled PLCs are an accessible and affordable way for most users to collect and create value from use field-sourced data.

Read more...