We are entering a new age in industrial automation and it is called ‘pervasive sensing’. Brought about by the advent of wireless technologies and the reduction of the cost of sensors, this event enables oil and gas refineries, chemical plants, mining sites and other industrial facilities to expand their use of sensors and extend the focus beyond traditional process control. Pervasive sensing allows the industry to get more and deeper data faster, providing it with greater visibility to operate increased safety, reliably and profitably.

Previously, the industry was limited to monitoring conditions that were critical to producing efficiently. Maintenance and reliability were addressed by conducting manual checks, which was time-consuming, inefficient, costly, and sometimes even risky – especially for personnel working in distant and hazardous production environments. And because finding failures was dependent on the frequency and quality of the manual checks, maintenance teams would usually discover equipment issues when the damage was already too big. While the industry has already recognised that this is not the ideal set-up, most producers stick to this practice because it provides reasonably stable operations.

Industrial wireless and affordable sensors are the drivers

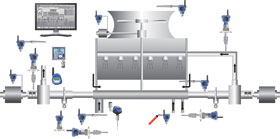

The availability of wireless, non-intrusive, affordable and easy-to-use sensors that can continuously monitor and detect operations is changing the status quo. Many industrial facilities are quickly adopting pervasive sensing strategies to be able to anticipate impending equipment failures and prevent unplanned outages. Plant personnel, for example, use a variety of wireless sensors to detect motor bearing or seal failures, identify pump cavitation, monitor equipment temperatures, and quickly see an array of faulty conditions that can affect operations.

In addition, industrial facilities are taking advantage of sensing technologies to extract value from their operations. An International Energy Agency (IEA) study states that regardless of which segment of industry one is in, there is a potential for 50% improvement in energy use, which is a big opportunity to save energy costs.

Safety and the environment are the focus

Safety and environment are focus areas of pervasive sensing. The industry wants the same thing in any plant anywhere in the world, and that is to achieve zero incidents. A global oil and gas producer with a hydrocarbon production facility in Belgium, for instance, implemented a wireless leak detection system that has enabled it to gather information from sensors which continuously monitor hazardous areas such as storage tanks, valves and pipelines throughout the plant, and to deliver information to the control system so plant personnel can be instantly notified of any leaks.

Because of wireless technology, this producer was able to eliminate the need for new instrumentation cabling and associated trenches and ducting, saving an estimated 50% of the cost and 90% of the time required to install a conventional wired system.

Pervasive sensing solutions are currently being deployed in many industrial facilities around the world today. As sensors continue to advance and wireless technologies continue to be widely adopted, the industry will be able to address its challenges and increase its ability to maximise production returns. The first step in harnessing pervasive sensing is to conduct an audit of the plant assets and current work practices and identify opportunities where sensing should be added.

For more information contact Ron Raubenheimer, Emerson Process Management, +27 (0)11 451 3700, [email protected], www.emersonprocess.com

| Tel: | +27 11 451 3700 |

| Fax: | +27 451 3800 |

| Email: | [email protected] |

| www: | www.emerson.com |

| Articles: | More information and articles about Emerson Automation Solutions |

© Technews Publishing (Pty) Ltd | All Rights Reserved