Helping Rand Water control the pH at the Zuikerbosch Purification Station.

Rand Water is the largest bulk water utility in Africa and one of the largest in the world, purifying and providing bulk potable water to more than 11 million people.

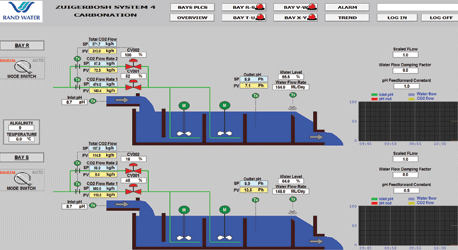

One of the purification steps involves the dosing of carbon dioxide gas for water stabilisation and pH correction. Due to operational requirements that necessitated the use of multiple treatment regimes, it had become apparent that the carbon dioxide dosing control system at the Zuikerbosch Purification Station was not coping adequately. After an initial investigation by Rand Water, it was found that the control system, which used only one valve for control, could not stabilise the water accurately under all operating conditions. Furthermore, it was found that the instrumentation and control equipment in use was old and outdated.

In order to improve the system, Rand Water identified that two control valves would be needed to cater for all treatment regimes. After an open tender process, the contract to upgrade the carbon dioxide control platform at System 4, Zuikerbosch Purification Station was awarded to Autotronix.

The scope of work ranged from designing, manufacturing and installing stainless steel pipe-work in accordance with ASME B31-Part 3, to upgrading all automation equipment such that it could operate on the local HMI and remote scada systems via Profibus and Ethernet networks.

The benefits were identified as:

* The ability to dose carbon dioxide gas from 3 kg/h to 1 000 kg/h accurately.

* The new distributed PLC control system provides for easy operation and maintenance with extra scada functionality and uniformity introduced.

* All equipment now interfaces with the HMI at the carbon dioxide dosing bays or scada in the control room via Ethernet and Profibus DP and PA networks (hardwired signals to the PLC were replaced by the Profibus network).

Implementation

During the functional specification design stage, process engineer at Rand Water, Vishay Bhoola, provided Autotronix with valuable input that influenced critical design decisions.

Rand Water specified the initial technical documentation from which the final designs were derived and developed by Autotronix in cooperation with a Rand Water technical team. Detailed design and sizing of control valves and general arrangement drawings for the pipe work and positioning of control valves were presented to Rand Water for approval.

Once approved, the installation of the new control valves, flow meters, pressure transmitters and connection of the actuator supply to each valve began. This was followed by the supply, delivery and installation of new control panels with PLC equipment, pH meter panels and junction boxes. Finally, the network and power cables with relevant trunking were delivered and installed.

The system allows for the ability to decrease the pH of water from high to the desired set-point given by the operators. When the system is allowed to operate in automatic mode the PLC performs the control calculations.

The PLC controller calculates the required amount of CO2 gas to dose in kg per hour based on the inlet, outlet and set-point pH, water flow rate through the bay, water alkalinity and water temperature. A special CO2 demand control block is processed and the output of this block is used to control the valves as necessary.

The existing PLCs were replaced by Schneider Quantum PLCs and supplied with detailed documentation to explain the operation and functionality of the new PLC code. New graphics were also developed to display plant status and facilitate easier control of the plant. An industrial fibre-optic Ethernet network was installed for the PLC and scada communications and the field instruments were integrated into the new Schneider Quantum PLC system via the use of a Profibus network.

Autotronix provided the Zuikerbosch Pumping water works with a one year quality guarantee and onsite support.

Autotronix’s company profile can be viewed at: http://www.instrumentation.co.za/36865n

For more information contact Haroon Bassa, Autotronix, +27 (0)31 705 0402, [email protected], www.autotronix.co.za

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

© Technews Publishing (Pty) Ltd | All Rights Reserved