Function blocks drive savings

June 2007

System Integration & Control Systems Design

Introduction

The concept of savings as a result of using software engineering standards is not new, but ITmatic have leveraged Profibus DP technology to extend this gain. In this example they built a standardised interface to the recently introduced ABB UMC22 motor starter.

Clients of ITmatic were recently able to benefit from:

* Reduced device configuration time.

* Elimination of the need for third party engineering and fault finding tools.

Functionality and savings

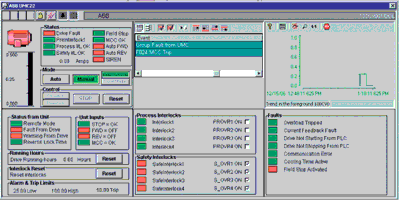

The faceplate in Figure 1 shows the functionality created for the ABB motor starter using a Siemens PCS7 V6.1 control system. While the motor starter provides standard functionality such as stop/start and fault displays it is possible using the device's Profibus DPV1 profile, to extract a host of valuable information and to write critical parameters to the unit. And since DPV1 is acyclical it is possible to do this without using up any additional bandwidth on the Profibus network.

Figure 1. ABB UMC22 motor starter faceplate displayed on Siemens PCS7 V6.1 control system

Reading parameters such as motor settings (ie, maximum current) from a starter in this way instead of hard coding or manually configuring access to drive communications in a control system saves vast amounts of time during initial commissioning. The saving is multiplied by the number of motors in a project. In our example the client had in excess of 200 motors.

Another advantage is realised when maintenance staff are required to make changes since programming staff are no longer required. This approach also helps to create clearly defined boundaries between disciplines. By reading device diagnostics via DPV1 and latching the alarm status fault displays can be centralised without resorting to third party diagnostic tools.

Additionally there is no requirement for other programming tools since the DPV1 interface allows critical operational settings such as alarm levels to be written to the starter.

For management, production and maintenance this approach also makes possible the reading of management information such as run hours or number of starts which can then be used for costing and preventive maintenance planning.

About ITmatic consulting services

It is the vision of ITmatic Consulting Services, part of the ITmatic Group of companies to 'manage the pre-implementation process and beyond' for its strategic clients. This includes the provision of services such as defining relevant standards or providing the necessary building blocks to reduce overall project cost.

For more information contact Petrus Klopper, ITmatic, +27 (0)82 559 7437, [email protected], www.itmatic.co.za

Further reading:

Modernising Vertical Filter Press Machines with Future-Focused Control Systems

System Integration & Control Systems Design

Project and Industry

Pressure Filter Specialists approached us to modernise vertical filter press machines for the Minerals and Metals industry. The goal was to improve reliability, reduce downtime,

...

Read more...

Project & industry

System Integration & Control Systems Design

Project and Industry

This project involved delivering a complete electrical, instrumentation, and automation solution for a new OEM drum-twister machine, replacing an ageing unit in a major cabling production

...

Read more...

It’s a risky business not to challenge standard language

System Integration & Control Systems Design

On the surface, contracts all look alike. Once you’ve seen one, you’ve seen them all, or so it seems. Maybe so, but hidden within the standard language can be language that shifts the other party’s risk to you.

Read more...

Containerised Electrical & Control System Powers Paste Plant in Botswana

System Integration & Control Systems Design

Delivering a complete, containerized solution for a mine’s paste plant in Botswana, this project stands as a model of modern EC&I execution — integrating electrical, control, and automation systems into

...

Read more...

Control system upgrade: Smelting

SAM Systems Automation & Management

System Integration & Control Systems Design

Systems Automation & Management recently completed a major control system upgrade in the smelting industry. The project was delivered on budget and achieved a positive ROI for the client.

Read more...

Gottwald drives upgrade: Ports and harbours

Abacus Automation

System Integration & Control Systems Design

In the ports and harbours sector, Abacus Automation completed a significant modernisation of a Gottwald crane, improving both operational reliability and serviceability.

Read more...

Mining industry upgrade: From ageing systems to maximum capacity

System Integration & Control Systems Design

Iritron recently undertook a major upgrade in the mining sector, focusing on washing and screening plants, jigs, thickeners, tailings, water systems, conveyors and reclaimers.

Read more...

Agogo Integrated West Hub Project: FPSO/subsea offshore Angola

Moore Process Controls

System Integration & Control Systems Design

The Agogo Integrated West Hub project represents a historic milestone in the FPSO and subsea industry, achieving first oil offshore of Angola. This project is the first FPSO deployment since ANPG’s establishment in 2019, and the first major project for Azule Energy since 2022.

Read more...

Integrated Robotics and Control Systems Deliver 45% Production Boost at Aquazania Waters Project and Industry

Process Dynamics

System Integration & Control Systems Design

Project and Industry Process Dynamics designed and commissioned a state-of-the-art Reverse Osmosis

(RO) water purification and automated bottle filling plant for Aquazania Waters in Linbro Park, Johannesburg.

...

Read more...

Project and Industry

System Integration & Control Systems Design

The Sicomp Control System Upgrade focused on modernising a 1985 power generation control system with more than 3 000 I/O points. The plant faced increasing system failures and risk to operational continuity,

...

Read more...