Saving valuable space on packaging machine plant

November 2000

System Integration & Control Systems Design

An OEM of food packaging machines produces a variety of packaging machines. Each machine has a small operator interface and a PLC with 24 to 80 digital and analog I/O.

On every machine, the electrical panel is limited by the size of the machine. The footprint dictates how much available space is available for control. The limiting space greatly reduces flexibility and the ability to expand packaging options.

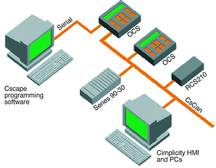

This is where the OCS (operator control station), from GE Fanuc, was a good choice, as it combines the OI and PLC functions into one small package that can be mounted in the operator's console. "We can use our limited panel space for other devices," said the design engineer. "We immediately recognised the advantages of the OCS when it was presented to us. Being able to do everything within one programming package will save us days of engineering design and checkout time. Not to mention the time saved by eliminating the integration task of the OI, PLC, and network."

The OCS controllers are powered by an Intel 296 microprocessor that has similar processing power capability to that of the Intel 486 mP. Each controller contains the hardware for a Control Area Network (CAN) interface that can be configured for CsCAN, or DeviceNet, Slave. The OCS comes in either a 2 or 4 line LCD display.

The optional SmartStack I/O modules are available in various DC and AC discrete voltages, as well as Analog, Thermocouple, and RTD versions. Each Smart Stack module is equipped with a removable I/O connector. Additional modules available include a high-speed counter, stepper motor controller, multi port ASCII/BASIC, and strain gauge.

The advantage of the OCS is the fully integrated controller, I/O, operator interface and networking in one package. The Cscape software combines the graphical ladder programming with the operator interface and networking to decrease the development time required. By combining the controller and operator interface, panel space is greatly reduced.

The speciality modules enable the OEM to expand into motion applications that were not available with their current controller. By using the Stepper Module and GE Fanuc SL Servo system, the packaging machines were more efficient and increased production capacity. Another advantage of the OCS is the standard CAN network. OEMs can now provide a high-speed network for their end customers at no extra charge.

Contel Plus

(011) 422 1246

[email protected]

Further reading:

Project & industry

System Integration & Control Systems Design

Project and Industry

This project involved delivering a complete electrical, instrumentation, and automation solution for a new OEM drum-twister machine, replacing an ageing unit in a major cabling production

...

Read more...

It’s a risky business not to challenge standard language

System Integration & Control Systems Design

On the surface, contracts all look alike. Once you’ve seen one, you’ve seen them all, or so it seems. Maybe so, but hidden within the standard language can be language that shifts the other party’s risk to you.

Read more...

Containerised Electrical & Control System Powers Paste Plant in Botswana

System Integration & Control Systems Design

Delivering a complete, containerized solution for a mine’s paste plant in Botswana, this project stands as a model of modern EC&I execution — integrating electrical, control, and automation systems into

...

Read more...

Control system upgrade: Smelting

SAM Systems Automation & Management

System Integration & Control Systems Design

Systems Automation & Management recently completed a major control system upgrade in the smelting industry. The project was delivered on budget and achieved a positive ROI for the client.

Read more...

Gottwald drives upgrade: Ports and harbours

Abacus Automation

System Integration & Control Systems Design

In the ports and harbours sector, Abacus Automation completed a significant modernisation of a Gottwald crane, improving both operational reliability and serviceability.

Read more...

Mining industry upgrade: From ageing systems to maximum capacity

System Integration & Control Systems Design

Iritron recently undertook a major upgrade in the mining sector, focusing on washing and screening plants, jigs, thickeners, tailings, water systems, conveyors and reclaimers.

Read more...

Agogo Integrated West Hub Project: FPSO/subsea offshore Angola

Moore Process Controls

System Integration & Control Systems Design

The Agogo Integrated West Hub project represents a historic milestone in the FPSO and subsea industry, achieving first oil offshore of Angola. This project is the first FPSO deployment since ANPG’s establishment in 2019, and the first major project for Azule Energy since 2022.

Read more...

Integrated Robotics and Control Systems Deliver 45% Production Boost at Aquazania Waters Project and Industry

Process Dynamics

System Integration & Control Systems Design

Project and Industry Process Dynamics designed and commissioned a state-of-the-art Reverse Osmosis

(RO) water purification and automated bottle filling plant for Aquazania Waters in Linbro Park, Johannesburg.

...

Read more...

Project and Industry

System Integration & Control Systems Design

The Sicomp Control System Upgrade focused on modernising a 1985 power generation control system with more than 3 000 I/O points. The plant faced increasing system failures and risk to operational continuity,

...

Read more...

Digital transformation from the edge

DirectLogic Automation

System Integration & Control Systems Design

Edge-enabled PLCs are an accessible and affordable way for most users to collect and create value from use field-sourced data.

Read more...