When it is vital that key plant process data is captured for tracking and KPI purposes, failures are simply not allowed. To ensure that data flows would remain uninterrupted and that the data would always be reliable and available, Mittal Steel's Electric Steel Making (ESM) plant at the Vanderbijlpark Works developed an intelligent information object to be used with ArchestrA's inherent redundancy feature.

Mittal Steel South Africa (formerly known as ISCOR) is the African continent's dominant steel producer, with a steel making capacity in excess of 7 million tons per annum. Mittal Steel, the South African producer's controlling shareholder, reached a 51% stake in the company in June 2004.

Mittal Steel South Africa has four steel making operations - Vanderbijlpark Steel and Saldanha Steel (flat products) as well as Newcastle Steel and Vereeniging Steel (long products). All four operations are ISO 9002 certified and enjoy ISO 14001 accreditation in recognition of their world-class environmental management systems. The company's Vanderbijlpark Steel operations produces 3,5 million tons of liquid steel a year, which constitutes 84% of South Africa's flat steel requirements. Extensive re-engineering of this operation has anchored its position among the world's most efficient producers.

Within the 2300 Ha Vanderbijlpark works is the ESM plant that consists of three arc furnaces, a secondary metallurgy facility and a twin-stand slab caster. Each arc furnace produces 150 tons of molten steel for every one of their 10 'heats' per day to yield a daily total of 4500 tons of steel of various grades.

In this environment, uninterrupted plant information is vital for the determination of its proper operation and prior to this installation, no provision was made for redundancy. The installation of ArchestrA at the ESM plant was therefore primarily done in order to ensure data availability between the plant control system and the process control information system by using ArchestrA's inherent redundancy feature and a newly-developed ArchestrA data information object.

The process control information system relies on critical signals (Heat on, heat start, Tap end, etc) from the plant to collate batch information about a heat. Other data such as chemical analyses and steel grade allocations etc, are also related to a heat, which, in turn is allocated to a cast number. So, for tracking purposes and key plant performance measurements (KPIs), this data needs to be reliable and available.

Mittal's ESM plant chose system integrator Ram-Tec Systems because of the company's proven expertise in the implementation of ArchestrA and its accreditation as a certified ArchestrA SI.

Business and operational objectives

The ESM plant was vulnerable to database malfunctions and, with the focus on increased output and efficiency to cope with increasing demands, this could not be tolerated. The decision was taken to strengthen the decision support information pipeline between the plant and the process control layer of the business while conforming to S95 standards.

Technology and approaches used

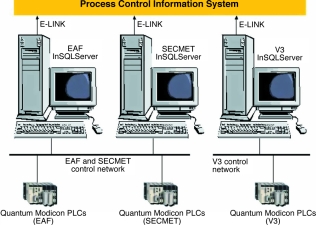

Previously, there was an IndustrialSQL historian server for each of the three areas of the plant (see Figure 1). This meant that if any of these servers failed, vital data would be irretrievably lost. One alternative to redundancy was to purchase a second hot standby including hardware and software but this proved more costly than installing ArchestrA, which not only provided the required functionality and could ensure the integrity of batching information but would also provide benefits through its ability to lower engineering costs. ArchestrA would also allow for the definition, deployment and maintenance of standards in a secure environment as well as provide the ability to easily balance computing loads between servers.

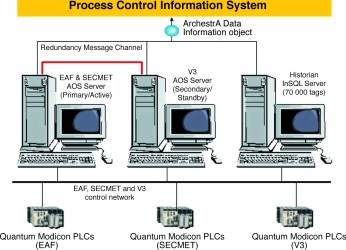

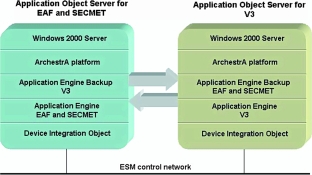

The current arrangement has transformed these three servers into a single historian and two ArchestrA-based application object servers (AOS). One AOS is responsible for the electric arc furnace (EAF) and secondary metallurgy (SECMET) sections and the other services the twin-stand slab caster (V3) (see Figure 2). In the event of a breakdown of either server, the other automatically takes over (see Figure 3).

One of the more unique approaches to the system was the initial approach towards vertical integration at the information level rather than the more conventional integration at the horizontal level of control.

"We chose ArchestrA for a number of reasons," says Joao Bordalo, senior architect, MES, Mittal Steel South Africa. "Firstly, it is a well-proven, flexible and scalable automation platform capable of unifying multiple and disparate scada platforms under a single umbrella irrespective of their geographical locations. Secondly, it conforms with S88 plant modelling standards while offering built-in software security and dual I/O server redundancy capability all at a reasonable price. Lastly, ArchestrA has proven 'Intelligent Object'-based functionality enabling advanced customised applications - such as was necessary in this case."

The rationale for choosing ArchestrA is usually its capability of unifying the automation environment and lowering engineering costs. ESM, however, decided to follow a different route. With the knowledge that ArchestrA could integrate sections of plants and entire plants, it was decided to first develop a data information object that would communicate collated and synthesise raw plant information and forward it to the process control information system.

Ram-Tec systems was assigned the task of developing this object that would include spooling and store-forward procedures so that no information is missed. This does not mean that there was anything wrong with the existing E-LINK system but that ESM would rather get the most from fewer software solutions. In fact, E-LINK will continue to be used with other applications.

One of the highlights of the implementation was its speed. Once Ram-Tec Systems had completed the design and development of the advanced information object for the electric arc furnace (about 60 man-hours), it was all over in less than an hour. The cycle was repeated for secondary metallurgy and this time it was completed in about 1/8 of the time taken originally and the benefits were realised immediately after that.

Integration with other systems

Through this implementation, ESM has shown that ArchestrA information objects can provide seamless integration not only horizontally to automation systems and databases but to the process control and business systems as well. Such an object, once developed, can simply be modified to suit specific applications with minimal effort. This approach provides a standard and unified means of communication with other applications while also giving access to plant control.

Results and business objectives achieved

* Full redundancy of the plant system means that it is virtually impossible to lose vital analytical data (eg, all the trended criteria for a heat, how much steel was tapped, how much scrap was used, power consumption, etc). Previously, the manual entry of lost data, if it could be retrieved, could take days and even then, it may not be accurate nor complete. The control data, on the other hand, would be lost irretrievably. This would compromise the reporting capabilities of the management information system, especially in the case of stoppages.

* The ArchestrA information object can be the single source of information for all dependent applications thereby eliminating interpretation errors. It can also be easily modified to suit a variety of requirements.

* ArchestrA has provided the ability to track, control and report on activities that were previously out of reach.

* The choice of ArchestrA over hot standby alternatives reduced costs while making the most of available assets and providing a lot more functional advantages.

* It has been shown that ArchestrA can be a vertical as well as horizontal tool for the integration of information.

* ArchestrA provides a common platform for information and control.

* ArchestrA is forcing the integration between IT and the world of realtime control.

* Reduced engineering costs on system expansion or duplication.

For more information contact Justin Tweedie, Futuristix, 0861WONDER, [email protected], www.futuristix.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved