It is important to have an accurate overview of the current program versions in use for all automation equipment, especially in complex production plants such as those used in car manufacture. Such procedures are mandatory if one wants to obtain ISO 900x certification. For this reason the BMW factory in Regensburg has decided to base its whole data management structure for the car body shop on this modern concept. A modular system is being deployed, which archives all versions and controls all changes of data. The automatic inventory control means an end to unnecessary conflicts, faster completion of program maintenance and an increase in the reliability of the whole system.

Software modifications are an everyday practice in production automation. Every expert knows the procedure when a plant is started up and its automation components are commissioned. Efforts are made at optimisation, modification and restructuring of program code until the desired result is achieved. In the heat of the moment the necessary data backup and documentation is all too easily neglected - at the end of the day considerably increasing time and effort required. This continues in the same fashion when the operation is running. Program enhancements are set to the wrong version and product lots cannot be assigned to the program that manufactured them. When malfunctions occur it is often impossible to quickly verify whether programs have been changed or are corrupted. When BMW were building their new body shop in Regensburg they declared their intention to be in a position from day one to document and archive, clearly and consistently, all changes to program versions and data files.

New concept

In order to cope with the increased tide of engineering data in the automated production area, the whole plant was networked via Ethernet-TCP/IP and Interbus. The old interference-prone manual data handling method, which used floppy disks and CDs, can now be dispensed with entirely. The main benefit however is that all the relevant data files can be accessed electronically from any location. Numerous backup copies on FD or CD with labels that have been overwritten countless times, and thick handbooks or documentation in folders, possibly outdated, are now all things of the past. One can say goodbye to filing cabinets and the maintenance of the paperwork and floppy disks stored in them. The main disadvantage of antiquated documentation, ie, the missing change documentation itself, is now avoided due to electronic acquisition and internal crosschecking. Despite a considerable increase in the quality of the data backup and management, cost and time expenditure on this important measure is actually reduced.

The introduction of the new data management system was preceded by intensive trials of a number of different software concepts over a period of 18 months. Here the stringent demands of BMW and the specific requirements of their automation equipment had to be met by the functionality offered by the different packages. The complex world of automotive manufacturing can be best represented by means of a very flexible system structure, which the user himself can configure and adapt.

Following conclusions of this preliminary system evaluation, the vehicle body production at BMW's Regensburg factory chose the modular VersionWorks software package from GEPA, the specialist data management company based in Landau, Germany. The crucial factor in the decision was the ability to integrate smoothly with any of the production automation equipment together with the possibility to analyse, document and archive all the volumes of data.

A true image of the real production process, as required for certification to ISO 900x, can only be obtained when both historic and current data is documented without gaps. The concept chosen by BMW is built on these requirements: PLC environment, field devices, PC applications (HMI, scada) and correspondence - Word or Excel documents can be captured as well as manuals in PDF format.

The hierarchy of the plant can be displayed in sections right down to detailed information of individual components. These system abilities mean that the user can benefit from closed loop control for his data and programs. All processes are comprehensively documented and thus easily traceable. For BMW's new vehicle body production this represents real progress in reducing operational errors and 'unproductive' information meetings. Each responsible person has access to all data that concerns him and this is automatically kept up-to-date. For this, the system is sub-divided according to areas of accountability, for example drive controllers, PLC, HMI, scada, Fieldbus, robot controller or welding devices are all dealt with as separate areas for data administration. Within these areas the data can be accessed right down to individual PLCs or even sensor or transducer set-up files.

Uniform in its complexity

A data management system such as that used in the body shop at BMW Regensburg can encompass a variety of totally different areas. Several hundred PLCs, hundreds of robot controllers and nearly as many PC workstations (HMI, scada) have to be monitored, as well as documentation of the data and changes to the software. Also to be included are further devices such as network components or discrete safety devices. The total can reach several thousand automation components. The chief advantage of the new system is the trouble-free integration of these many devices and operations under one umbrella. This means the individual areas can benefit from fast reliable access to accurate data, verify programs by 'smart compare' or localise problems through data analysis. Compared with the old system of decentralised manual data backup the new system represents a quantum leap in data management.

Centrally managed - individually designed

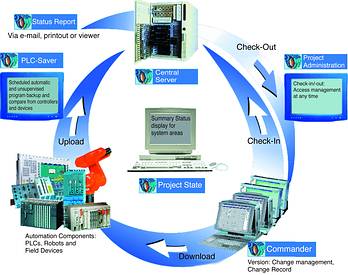

The system's mode of operation is simple to understand: a server hosts all the relevant data and program versions in subgroups specific to the factory. The currently executed programs and data reside on the local control computers, the devices. Changes can be made via a client PC, eg, programming device or laptop, either from a desk or just as easily on shop floor. Each client - depending on his user rights - can undertake changes, version revisions and archiving on the server.

The regular automatic device program backup additionally checks that the server archive is up-to-date. If changes have been made without updating the server, the difference is detected and the responsible person informed by e-mail. A quick and powerful verification can be performed on demand and differences are displayed in 'smart compare' mode between the documented program and the program currently running (for example, down to the STL code level for Simatic S7). Corrective measures can follow immediately. It is no longer possible for an unauthorised program change to go undetected. Accurately documented, older versions are available for comparison with the new version or for restore purposes. The often neglected risk assessment and management with the software is thus convincingly integrated.

Even a change in the PLC or computer program is picked up by the cyclic check and the information passed on. This means that changes or errors in settings, for example after maintenance work, are quickly detected and possible consequential costs kept to a minimum - or avoided altogether. Automated, frequent verification of device programs not only helps to identify the causes of variation in product quality, but also can significantly reduce the risk of damage to personnel and machinery due to software changes.

A key benefit here is the fast and easy retrieval of data. All changes can be tracked and, if applicable, rectified or undone. Transparency is always maintained in spite of these possibilities, as the system automatically backs up, compares and archives the current changes. However to truly track software history, not only the changes themselves need to be archived, but also the reasons for them. More than enough space is available for this additional information.

For more information contact SAM System Automation & Management SA, 011 803 0570, [email protected], www.sam.co.za, www.versionworks.com

For the BMW factory in Regensburg the introduction of a purely software-based data backup and automation data management system meant a drastic reduction in time and expenditure in this area. The standardised central administration of all plant automation data on one server increases the security and availability of the whole volume of data. The new data management system is user-friendly and does not require any special system expertise. Downtime resulting from replacing faulty hardware components and restoring programs or installing software improvements is substantially reduced since all the necessary data is always readily available. The production quality and security can achieve levels not previously possible, despite increased demands and greater volumes of data.

| Tel: | +27 11 803 0570 |

| Email: | [email protected] |

| www: | www.sam.co.za |

| Articles: | More information and articles about SAM Systems Automation & Management |

© Technews Publishing (Pty) Ltd | All Rights Reserved