The face of integration is changing. Companies are recognising the need to get beyond just moving information throughout the automation and business systems. That model simply transfers information from one layer to another, maintaining disparate silos of information and duplication of data and functionality.

FactoryTalk is a scalable information platform that integrates plant-wide control systems and connects the enterprise with the production facility. It uses a new concept - based on shared services and federated data - that allows enterprise components to share and access information and resources throughout the system, eliminating integration hassles, information silos and functionality overlaps.

FactoryTalk enabling technologies, including FactoryTalk Directory, FactoryTalk Live Data, and FactoryTalk Diagnostics, provide specific capabilities to help manufacturers share common factory resources, access information across the enterprise, and track global system changes.

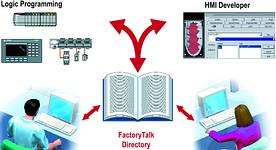

FactoryTalk Directory

FactoryTalk-enabled products use FactoryTalk Directory, which provides a common address book of factory resources so that changes to the automation system are updated automatically across FactoryTalk-enabled applications. The common address book of information allows data to exist in native locations, such as within controllers, graphics servers, and other types of servers in the system, but be referenced from anywhere. For example, components that need to access a tag database 'look up' the database location and form a link to that information, allowing the information to be federated into the system (Figure 1).

The federated data model has no single point of failure and maintains information integrity because data is shared, not duplicated - across applications. Changes made to the automation system automatically update across all participants in a FactoryTalk-enabled application.

FactoryTalk Live Data

FactoryTalk Live Data enables enterprise-wide access to realtime manufacturing information by managing connections between FactoryTalk-enabled products and data servers. It notifies clients when a connection is lost, automatically reconnects, and combines data from multiple controllers and servers into a single group with a single data server connection. This results in faster realtime data transfer and more reliable, efficient connections to data servers. It also assists in redundancy support for data servers by automatically handling detection and failovers for all FactoryTalk-enabled products.

FactoryTalk Live Data also allows the automation system to be extended, using third-party hardware and software solutions. A feature of FactoryTalk Live Data is its ability to provide flexible redundancy support for any OPC-compliant data server, regardless of manufacturer, by automatically handling detection and failovers for all FactoryTalk-enabled products - without custom programming.

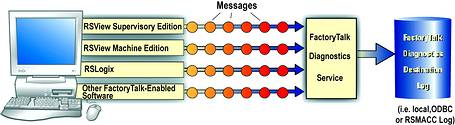

FactoryTalk Diagnostics

FactoryTalk Diagnostics collects and routes the activity, status, warning, and error messages generated by all FactoryTalk-enabled components on a given computer to a common local log - enabling users to diagnose problems on the computer in question.

To help diagnose network-wide problems, FactoryTalk Diagnostics can merge each computer's log into a central, network-wide database for further analysis and/or archiving.

FactoryTalk Diagnostics can route change information to a centralised RSMACC repository for auditing plant-wide maintenance information associated with change management and asset health. This is particularly important for companies that must comply with US government regulations in the pharmaceutical and food and beverage industries. With built-in diagnostic capabilities, FactoryTalk-enabled products can monitor system changes, generate detailed audit messages, and route messages to a central database, where they are available for tracking, analysis and reporting.

FactoryTalk benefits

Benefits include: reduced initial development time and ongoing maintenance costs, improved product quality, easier validation efforts, improved equipment performance and uptime, elimination of duplicate efforts, better optimisation of plant resources, faster time to market and better supply chain utilisation. The FactoryTalk automation platform components are included when purchasing FactoryTalk-enabled products from Rockwell Software.

Fact Box

FactoryTalk-enabled Rockwell Software Products.

RSView Machine Edition

Enabled by FactoryTalk Directory, RSView Machine Edition allows users to browse local directories for RSLogix tag addresses and direct access controller tags. RSView Machine Edition takes advantage of FactoryTalk Live Data capabilities, providing fast, reliable access to realtime plant-floor data.

RSView Supervisory Edition

RSView Supervisory Edition uses FactoryTalk Directory to directly access tags via RSLinx and OPC 2.0 data servers. FactoryTalk provides an aggregate directory of all tags and structured information in the system. It takes advantage of FactoryTalk Live Data capabilities, providing fast, reliable access to realtime plant-floor data. It also assists in redundancy support for data servers by automatically handling failure detection and fallovers.

RSAutomation Desktop

RSAutomation Desktop helps companies manage multiple, complex automation projects simultaneously without overwriting other projects. Because its versioning system is tied into FactoryTalk Audit, you can immediately view messages about changes to any element of the project across the entire automation system. This eliminates conflicting edits and duplicate efforts from team members and helps quickly identify who made changes to project elements, when, and why.

RSMACC

RSMACC (Maintenance Automation Control Centre) detects and records altered electronic files required to comply with regulations, such as the US FDA's 21 CFR Part 11 specification. Enabled by FactoryTalk Audit, RSMACC provides a centralised repository for auditing plant-wide maintenance information associated with change management and asset health.

RSBizWare - RSSql

This is a Windows-based industrial transaction processing system that provides a two-way link between control systems and enterprise database systems. When participating in a FactoryTalk application, RSSql has access to all data items available through FactoryTalk Directory, which it then makes available to other RSBizWare products.

For more information contact Jeff Sandison, Rockwell Automation, 011 654 9700, [email protected]

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved