Papermaking machines are bigger and faster than ever. This fact of life does not surprise anybody, but we often forget how the change has affected demands for controlling the process. Papermakers accept less variation in raw materials and process variables; grade changes have to be faster; less web breaks are allowed.

Uniform pulp

It is important to know the nature of the pulp in the process. Obviously we want to control certain properties like drainage potential (freeness), fibre fractions, strength of the pulp, brightness, different recipes and mass balance. A surprise to some, consistency control is extremely important, as it influences all the properties just mentioned. Uniform pulp cannot be made without proper consistency control.

Consistency

While the concept of mass flow is easy to understand (tons per day or kg per second), to establish the actual mass flow requires multiplying volumetric flow by the density (a function of the consistency), giving mass flow as an output. In other words, mass flow cannot be calculated without representative density measurement - which is reliant on consistency.

Drainage potential or freeness

Today, refiners are controlled using SEC (specific energy control) where fixed amount of energy is used per refined ton of pulp. Pulp loses strength if too much energy is used for refining, not to mention the energy wastage. On the other hand, if inadequate energy is used, freeness will remain too high, typically resulting in runnability problems on the machine.

The amount of refined pulp cannot be calculated without accurate density measurement. Screening is also critical for freeness, shives and fractions. Screens exhibit a very narrow tolerance when it comes to feed consistency. If feed consistency varies, quality of accepted pulp can be ruined. Also, rejected pulp, which is typically fed to second stage feed, can block the reject line of the second stage and this can ultimately block the entire screening system completely.

Bleaching chemicals dosing is controlled by mass flow. Chemical and fibre losses are the natural result of being heavy-handed with chemicals per bleached ton. Web strength depends on the recipes. Often papermakers are overdosing chemical pulp due to good strength properties to avoid web breaks. At the same time they are wasting money, because each extra percentage of chemical pulp costs a fortune at the end of the day.

As raw material is the most significant component in cost structure of manufactured paper - and profit margins are low - improved consistency control can save a lot in raw material cost, as well as greater machine efficiency. Considering the need for fast return on investment (ROI), it is obvious that consistency control is definitely one of the key elements in the papermaking process. But, still it is one of the forgotten or misunderstood measurements.

Consistency management

Consistency control is often understood as a transmitter and dilution control valve, but it is much more; there can be six components which all are important to make consistency control possible.

1. Process know-how.

2. Correct transmitter selection.

3. Sample valve.

4. Laboratory procedure.

5. Control strategy.

6. Dilution loop.

This should be very clear. If we are not aware what is happening in the process, our capability to control it is very limited. Nothing much can be done if one simply installs a transmitter thinking that this will solve any problems. The problem has to be clarified and understood before the appropriate corrective action can be taken. Care must be taken when installing a consistency transmitter: Can it measure properly where it is intended to be installed? Are the process conditions suitable for this particular type of transmitter?

Correct transmitter selection

There are three major technologies available for consistency measurement:

1. Shear force transmitters.

2. Optical transmitters.

3. Microwave transmitters.

Each of these technologies has their own advantages and disadvantages. Shear force transmitters have been around for 40 years. They measure fibre friction caused by pulp flow. These transmitters can measure fibres only, but in many cases there are no fillers in the process or fibre consistency alone is needed.

There are blade type and rotating type transmitters available. While they look very different, they measure the same physical phenomena: shear force. These transmitters are well known and they perform well with clean pulps but in applications where pulps are mixed, they do not give consistently accurate measurements. These are the most common products for consistency measurement >1,5% Cs, although they are sensitive to fibre properties.

Optical transmitters have been available for the last 20 years. They can measure both fibres and fillers, but usually sensitivity to fillers is different to sensitivity to fibres. Also, most optical technologies are sensitive to colour and brightness variation, but there are certain applications where these transmitters can be the best choice, especially in low consistency applications (below 1,5% Cs).

Microwave transmitters were launched five years ago. This technology offers a new aspect to measure consistency. Finally, a transmitter, which is insensitive to wood species or pulp grades, insensitive to freeness, colour, brightness and flow rates. Microwave transmitters do measure both fibres and fillers and that is why it is known as a total consistency transmitter. Most of the microwave transmitters have been installed in mixing chest or machine chest applications, where other technologies get into trouble due to variations in fibre properties like fibre length and filler content.

Sample valve

Calibration of a consistency transmitter is not an easy task. Most of the industrial transmitters (like pressure transmitters) can be calibrated on the bench using accurate calibrators. When calibrating consistency transmitters we have to take a sample from the process line and hope that the sample we have got is representative. Then the sample is analysed in a laboratory. This is another source of error when calibrating the consistency transmitter.

Often, mills use ball valves for sampling (because they are inexpensive) and often the machine suppliers have already installed them. These ball valves can never give a representative sample. Repeatability of sampling procedure is low due to their dependence on exactly how different individuals take the sample. Since the sample is taken from the edge of the main flow, it typically contains a greater proportion of water than is present in the full cross section of the flow.

Proper samplers have to be used to avoid bad sampling. Samplers equipped with a nozzle, which extracts from the main flow - and have on/off action, are required. This is the only sure way to eliminate the effect of variable process conditions and variations contributed by the operators' individual sampling techniques.

Safety is another feature that should never be forgotten: Proper sample valves have been designed to meet the strictest safety requirements. The best ones are equipped with pneumatic actuators. Then the best possible location can be chosen for the sampler to get representative samples safely.

Laboratory procedure

The laboratory personnel justify performance of the consistency transmitter. A common fallacy is that the laboratory result is the absolute truth, often forgetting that tappi - standard t240 gives only 10% repeatability for the testing method. Educated laboratory persons can get better results, especially with low consistency samples, but very often deviation between persons can be significant. So - especially when doing follow up for certain consistency loops - only one person should be nominated for that procedure.

Control strategy

Consistency control typically consists of consistency transmitter, sample valve, dilution valve, pump, and chest or tower. Single PI-control is the most common solution and usually it works just fine. But there are also problem cases, where either tower consistency or mass flow to the paper machine may vary a lot. Double dilution is required if tower consistency varies significantly. Other applications where this arrangement should be used are blow lines and some machine pulpers.

Dilution loop

Good dilution loop consists of high performance control valve (sizing and operation) and constant process conditions in dilution water loop (quality and temperature of dilution water and constant backpressure).

The valve has to be sized and selected correctly, sizing programs capable of analysing valve performance under installed conditions (like installed characteristics and gain) are recommended for valve selection. General requirements for a high performance control valve are low hysteresis and a narrow dead band, fast response and wide operational region. New generation digital valve controllers with improved control performance are recommended to meet these requirements. When digital valve controllers are capable of control valve diagnostics needed for predictive maintenance, then long-term performance can be attained.

Most of the problems in dilution loops come with inconstant backpressure. This can ruin the dilution loop completely. If constant backpressure cannot be assured, there are control valves available that can measure flow through the valve. This can eliminate variation in the dilution loop.

Summary of consistency management

As a summary of consistency management, it is safe to say: DO NOT look at the consistency transmitter only when having trouble with consistency control - most often the problem is not there. Check the following details first:

1. Chest/tower, mixing, chest level.

2. Process, can it be controlled?

3. Piping, flow conditions.

4. Control valve, size and operation, control strategy.

5. Dilution water, quality, pressure, temperature.

6. Installation of the consistency transmitter and sampler, have they been installed according manufacturer's specifications?

7. Sampler itself, is it possible to obtain consistent, representative samples?

8. Sampling procedure, same procedure every time?

9. Laboratory analysis.

10. Analysis and actions, also those made in the past (calibration).

Test results

Now, with a clear understanding of paper consistency management, we are in a position to focus on some detailed applications. How does correct transmitter selection and control strategy affect the papermaking process?

Total consistency versus fibre consistency

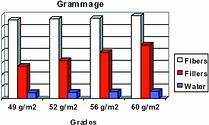

This is a common discussion. Which one should be measured - fibres only or total consistency (fibres and fillers)? There are applications where only fibre consistency is required, applications like refining and bleaching. When it comes to the broke system and mixing chest/machine chest applications, total consistency must be known - because that is what is seen on the final product, the paper. Paper is fibres, fillers and a small percentage of water. Here we have an example (Figure 1), where it can be seen what SC-grades typically consist of. Most of the grade change has been made adding fillers. Fibre content remains almost the same. Fibre consistency alone (measured by a shear force transmitter) is clearly not a solution for this application.

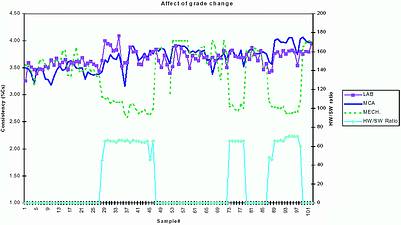

Effect of grade changes

Grade changes affect most of the consistency transmitters. Usually sensitivity to fibre length and inability to measure fillers cause these problems. Here is a test result (Figure 2) from the machine chest of a board machine, where they made a head to head test using shear force transmitter and microwave transmitter: The shear force transmitter was calibrated for 100% hardwood and it is performing well with this grade. When changing a recipe to 60% softwood and 40% hardwood, the output of shear force transmitter changes by 0,8%Cs. The microwave transmitter output did not change. This clearly illustrates that microwave transmitters are definitely the best choice for applications where fibre properties are changing.

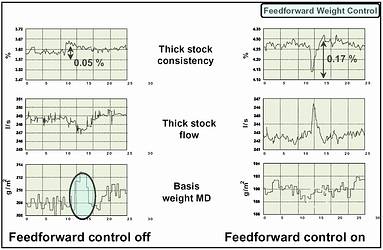

Feed-forward control

Typically MD basis weight is controlled using a scanner signal as a measurement signal and which is used to control the opening of the basis weight valve. This is how it has been done for years. The problem with this arrangement is that the signal is delayed. An error in consistency after machine chest takes three to four minutes to propagate through the system and cause the BW-valve to take corrective action. That is too late. Feed-forward control can eliminate these errors. When consistency transmitter measures an error in thick stock consistency, the corrective action is made immediately and error is eliminated before it gets into the headbox and finally to the paper.

Here are the test results (see Figure 3). On the left-hand side is a normal control loop and 0,05%Cs error goes through the system. Corrective action is made too late (when the scanner measures it). Effect on the paper is clearly seen. On the right-hand side there is an error, actually three times larger than in the first case. Corrective action is made immediately and basis weight remains stable. Feed-forward control is today's technology for better basis weight control.

Papermakers require better consistency control and it can be realised at the mill sites if the whole picture is understood. The consistency management concept was made for that purpose. Better consistency control means:

* Better paper quality.

* Better runnability.

* Saving in raw materials.

This all means more profitable papermaking.

For more information contact Steve Clark, Metso Automation, 083 289 6891, [email protected], www.metso.com

© Technews Publishing (Pty) Ltd | All Rights Reserved