The size and complexity of present-day mining activities calls for precise methods in planning and operations. This requires design and implementation of systems that are effective, flexible, efficient and cost effective over the life of a mine.

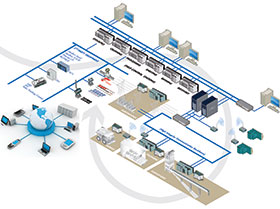

Having the correct infrastructure in place is paramount for all mining activities. Whether there is a need to control simple but critical mine applications (such as underground dewatering, shaft ventilation systems, mine water supply, tailings dam control, ore crushing, stacker reclaimers, spreaders and conveyor belt control); more precise control applications (such as ball and SAG mill controls, rougher and scavenger flotation circuits and concentrate cake dewatering machines such as filter presses); or control of mine utility supplies (such as air compressors, reagent plants and ice storage plants); Yokogawa’s PLC and scada control system packages are suitable for all modern mining applications.

Efficient and cost effective solutions

For efficient and cost effective modern mining, Yokogawa’s Stardom network-based PLCs and Fast/Tools Scada package is a perfect fit. The Stardom controllers are designed to function as a control platform with the goal of achieving excellent applications ensuring mines maintain their competitive advantage in a rapidly changing market. This platform provides several benefits including increased uptime and reduced inventory through the shared use of reliable, hot swappable modules. Reduced engineering and maintenance workload is realised thanks to the improved reusability of programme components. Another advantage is the enhanced capability to respond in a timely fashion to rapidly changing market requirements through the adoption of flexible software architecture and the use of advanced IT functions.

Autonomous controllers

The Stardom autonomous controllers are available in three versions:

• FCN (field control node).

• FCN-RTU (remote terminal unit).

• FCJ (field control junction).

All are highly reliable, intelligent controllers having memory with error-correcting code (ECC) and a wealth of reliability, availability and service (RAS) features on a rugged hardware platform. They are able to carry out regulatory and sequence control, such as PID loop control. For engineering descriptive coding, five IEC 61131-3-compliant programming languages are supported. These controllers also serve as Java virtual machines, allowing file transfers using the FTP protocol, autonomous event notifications by e-mail, and web server applications and user-developed Java applets to run.

The FCN is a modulus controller assembled with CPU, I/O, and other modules as necessary. It supports a variety of I/O modules, has superb expandability, and can build a highly reliable system with its power supply, CPU, and control network.

The FCN-RTU low power autonomous controller is a modulus compact controller assembled with a CPU module with built-in analogue, digital I/O, communication ports, and a short base module. Three arbitrary I/O modules can be installed. Its low power consumption (75% less than existing Yokogawa products) and ability to operate in extreme temperatures (-40 to 70°C) as well as thin air altitudes (up to 3000 m) make it perfect for those remote and harsh environment applications.

The FCJ is an all-in-one controller with a built-in I/O interface, ideal for installing inside machine equipment as well as configuring a distributed system for applications with limited I/O.

Fast/Tools Scada

In combination with the Stardom controllers, Yokogawa’s state-of-the-art Fast/Tools Scada offers improved visualisation, deployment, connectivity and alarm management, as well as data storage and management for most mine control and asset management applications.

Fast/Tools is a web-based real-time operations management and visualisation software suite that brings revolutionary changes to real-time process information intelligence. This enterprise operations solution has architectural benefits that significantly advance efficiency, security and improve operational agility of remote process management infrastructures. Whether working in a central control room or on site, the workflow processes are the same.

Conclusion

As the mining industry moves into a new era where productivity, effectiveness, efficiency and cost management through innovation will be crucial, Yokogawa is well positioned to be the key partner in all mining control applications.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved