Systems Automation and Management (SAM) has developed methodologies, using various products and engineering knowhow, to give its clients a control system upgrade without breaking the budget. Thus all the functionality of a new control system can be achieved without replacing all the legacy hardware and software. The implemented technologies set the foundation for future expansion and modification.

The issues today when upgrading a control system on an existing plant are as follows:

* Budgets have been squeezed to do the work and major upgrades can severely affect the cash flow of the company.

* A phased approach to upgrading the plant is required, while still setting a technology foundation for future upgrade phases.

* No company can afford to shut down their plant for any length of time, so upgrades usually have to be done slowly during planned outages.

* There is always a risk that an upgrade will result in production downtime.

* Product life cycles are becoming shorter. Clients are looking to extend their investments in the control systems in order to maximise their return on investment.

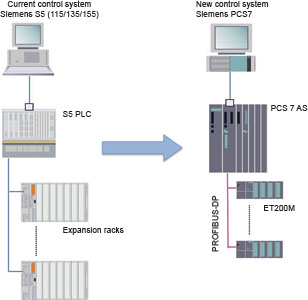

Phase 1 CPU upgrade

The first step is to replace the existing S5 CPU cards with the new dual control system X5/X7 CPUs. The X5/X7 CPU can execute both the Simatic Step 5 and Step 7/PCS7 programmes simultaneously. The CPU also has a four-port Ethernet switch on board. This allows one to run the existing S5 inputs and outputs as well as the existing Simatic S5 software on the new X5/X7 CPU and communicate with any scada system. By using the existing software, the changeover of the CPUs and connection to Ethernet can be achieved in a matter of hours.

During this phase, SAM will be able to connect previously non-networked control systems to other major PLC brands on an industrial network and communicate to any scada system. Further, the old HMI/Scada can usually be run in parallel with the new system. This allows time to check correct functionality of the new system and also gives plant personnel time to accept and adapt to the new technology.

Phase 2 hardware upgrade

The second step in the upgrade process is to replace the existing PLC I/O cards in expansion racks and remote I/O racks with new S7 remote I/O racks. At this stage, the client can elect to introduce technologies such as field buses, remote I/O in the field, new intelligent instrumentation, as well as intelligent energy meters.

By introducing these new technologies, a vast amount of additional information can be extracted, stored in the historian and used for data analysis and production optimisation.

The upgrade process can be stopped at this stage and run with a combination of new PLC hardware and old PLC software. SAM has secured the agency of several companies who specialise in repairing and supplying old PLC modules, thus eliminating any problem with legacy spares.

Phase 3 software development

The third phase of the upgrade process involves developing the new control system software. In parallel to the systematic change-over of the old S5 hardware to S7 hardware, the new PCS7 software can be developed and tested.

At this stage PCS7 specific ‘Controls/Software Standards’ can be developed that will include functionality such as intelligent alarm management, plant sequencing, work flows, intelligent maintenance systems etc. Furthermore, links to the ERP system can be established for data exchange. During maintenance shutdowns, the old software can be disabled, and the new software enabled and commissioned.

If the engineers encounter problems with the new software while testing on the plant, they can always reinstate the old software and get the plant up and running, without any risk of production loss. The fact that this feature is available means that the engineers are not under excessive stress to get the new software running, which allows them to concentrate on developing quality software.

During this phase all new software can be checked without affecting the plant, thus the new software can use the feedback from the actual plant for true plant simulation.

Phase 4 replication

Once the new PCS7 software for one plant section has been proven to the satisfaction of the client, the next plant section can be upgraded using the same procedures as above.

Conclusion

This methodology minimises the client’s risks both in terms of production downtime and cash flow and the processes allow them to proceed cautiously with the upgrade and manage the phases in accordingly.

The latest control and automation technologies can be deployed rapidly and the client can take advantage of these technologies to maximise ROI at a fraction of a complete control system upgrade. Depending on the client’s particular plant and respective needs, the above four phases can be extended to incorporate several combinations and intermediate steps in to the upgrade plan.

The issues related to controls system upgrades as initially stated can be addressed and their impacts minimised by utilising the experience gained and methodology developed by SAM over several years.

| Tel: | +27 11 803 0570 |

| Email: | [email protected] |

| www: | www.sam.co.za |

| Articles: | More information and articles about SAM Systems Automation & Management |

© Technews Publishing (Pty) Ltd | All Rights Reserved