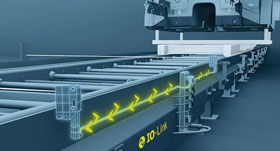

The question is no longer whether to enter Industry 4.0, but instead how best to do it. At the sensor and actuator level, IO-Link makes it possible to network production with a manageable degree of effort. It brings additional intelligence to the field level and enables the devices to be connected in end-to-end communication, which can extend right through to the cloud. New IO-Link masters, which also understand OPC UA and MQTT, help with this. The globally available and widely used IO-Link standard allows communication solutions to be implemented without the need for proprietary protocols.

Why use IO-Link?

Simple is successful: IO-Link is a great example of this principle. Through the use of the existing point-to-point connections and the standard three-wire system, IO-Link provides a downward compatible interface for binary standard sensors.

Identical wiring maximises the utilisation rate for IO-Link masters based on the combined operation of IO-Link signals and digital signals. IO-Link sensors can also be connected to conventional digital inputs; the integration is fieldbus-independent and possible in any network. There were already over eight million IO-Link network nodes in the field at the start of this year. The standard has established itself as the basic technology on every continent and in practically all industrial sectors.

Since microcontrollers are integrated into practically all modern sensors, the basis for device intelligence is generally available in addition to the actual function. Not only do they provide the actual measured value or switch point, they also supply additional information about the signal quality and device health, for instance. Their on-board electronics can save parameter sets to adapt the sensor to the application in question. This means that settings can be changed even during operation and processes can be designed in a flexible manner. The cost-effective production of even the smallest batch sizes becomes a realistic option.

Intelligence connection

IO-Link has established itself as the communication protocol for the ‘last metre’ because it enables this potential of the microcontrollers to be fully exploited. It allows easy online identification of the device, as well as the configuration and modification of parameters. It is also used to transmit measuring and switching signals, enable diagnostic functions, and provide excellent process transparency overall. Complex sensor systems and closed fieldbus environments are no longer required to achieve this.

With these functions, IO-Link makes it possible to use important value-added functions. These include preventive maintenance, a simple restart procedure following sensor replacement, and, if necessary, a detailed overview of the plant as a whole. At the same time, it meets the requirement of vertical connection between the field level and the IT network imposed by Industry 4.0 by making the data available to higher levels. The IO-Link standard provides the basis for bidirectional communication with the field devices.

Clear profile for sensors

There is now a set of rules for the standardised transmission and mapping of sensor data available for IO-Link in the form of the Smart Sensor Profile. It includes identification, diagnostics, process data variables, switching signal, and teach-in. For these function classes, the read/write objects, such as the arrangement of the binary information for switching signals, have a fixed definition.

In the Legacy Profile, a basic data stock provides the basis for uniform device behaviour. In the Common Profile, data is stored for more detailed identification and diagnosis. They define identification parameters for the application, function, and operating location and offer significant added value for asset management. Basic diagnostic data that provides information about the state of the device and about upcoming events is also stored.

Different data profiles are defined for different categories of sensor (fixed switch point, configurable switch point, measuring) accordingly. The parameterisation therefore always follows a predetermined pattern, and the process values can be interpreted uniformly. This uniformity makes integration and operation much easier.

Opening up the field level to the cloud

In addition to this uniformity, IO-Link has also recently taken a big step in terms of communication options ‘upward’. The OPC UA for IO-Link companion specification was recently published. The connection of standard access to the Ethernet world via IO-Link means that a transition between the two areas is now possible without the need for proprietary protocols.

Pepperl+Fuchs Comtrol is the first provider to have brought an IO-Link master with a corresponding OPC UA interface to market. Components with an MQTT interface are also available. The new Pepperl+Fuchs subsidiary was established at the end of 2018 through the acquisition of business operations from Comtrol, a US company and pioneer of industrial networking. Its main focus is the integration of industrial applications on Ethernet and in the cloud. The portfolio includes a wide range of gateway components with IO-Link connection.

The combination of the IO-Link and OPC UA standard protocols paves the way for the retrieval of data from the field level without any restrictions. The hierarchy boundaries can be overcome with minimal effort. In addition, process data can be transferred in parallel through the OPC UA interface. The user receives a real-time overview of the production or logistics situation. With the appropriate configuration and approval, this can be accessed in the cloud from anywhere.

Comprehensive complete solutions

Pepperl+Fuchs Comtrol also offers interface converters from the DeviceMaster family, which interpret between serial interfaces (RS-232/422/485) and TCP/IP protocols. This allows installed assets to be integrated into the PC world without the need for restructuring. The DeviceMaster with additional gateway function is able to convert RS-232/422/485 and TCP/IP into the deterministic Profinet and EtherNet/IP protocols. There are device versions that connect to Profinet or to Ethernet. Both also support Modbus and allow connection to common controllers and HMI.

These products overcome the boundaries between previously separate areas. In doing so, they help to ensure the end-to-end data flow required for Industry 4.0 and IIoT at crucial points. The ubiquitous availability of information creates process transparency.

The cloud – whether on the Internet or provided locally – can be used for condition monitoring and predictive maintenance without technicians having to deal with the sensor technology. If cloud applications are to be implemented, the Pepperl+Fuchs subsidiary Neoception can handle the application-specific development. Users can therefore get virtually all types of sensor, the transmission technology, and the software solution from a single source.

| Tel: | +27 10 430 0250 |

| Email: | [email protected] |

| www: | www.pepperl-fuchs.com/en-za |

| Articles: | More information and articles about Pepperl+Fuchs |

© Technews Publishing (Pty) Ltd | All Rights Reserved