Heating, ventilation and air conditioning (HVAC) is the technology of indoor and vehicular environmental comfort. HVAC systems are mostly used in hypermarkets to provide shoppers comfort and acceptable indoor air quality, but they also consume massive amounts of energy. In order to optimise energy consumption, traditional HVAC systems collect energy usage data at intervals. Although traditional systems are good at retrieving energy consumption data, they lack rules-based logic capabilities to interpret the data and determine further action. Therefore, most HVAC systems rely on human operators to manually adjust the system based on its current environmental temperature, as essential equipment, such as chillers, pumps, and fans, is not connected to a network.

Adopting sensors to acquire real-time data is not always that straightforward because of interoperability issues among the large variety of protocols in a network, making it a very costly upgrade to overcome this challenge. Another hurdle is translating data into a timely response through automatically adjusted settings to optimise energy savings. A hypermarket required an IIoT solution that connected chillers, pumps, fans, and sensors to enable automated demand response control of the HVAC system, based on the real-time temperature and business hours, to decrease the activation time of chiller systems and help the hypermarket save energy and reduce operating costs.

System requirements included:

• A timely response to automatically control the HVAC system based on business hours and the current environmental conditions of the hypermarket.

• Tracking energy usage anytime and anywhere to ensure continuous energy efficiency by acquiring and analysing data from the HVAC system (e.g., water-cooled chiller temperature, power consumption, etc.)

The Moxa solution: active energy efficiency with minimum programming effort

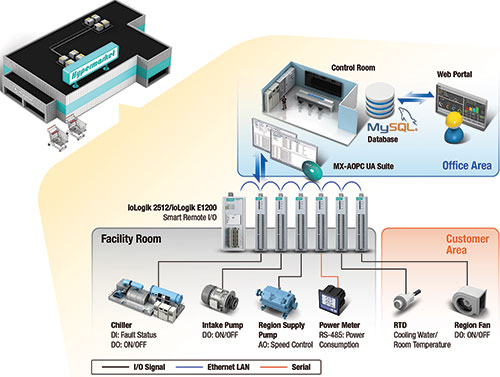

By deploying resistance temperature detector (RTD) sensors, power meters, and Ethernet remote I/O in the physical environment, real-time serial, digital, and analog data about the environmental temperature, water-cooled chiller temperature, pump speed, and power consumption can be acquired and transmitted to the database to determine further action.

To automatically enable the settings adjustment of the chiller, pump and fan, based on the real-time temperature in the hypermarket, the commands to regulate the functioning of the smart HVAC can be set by Click&Go; Plus, a programming-free control logic that is included in the Ethernet remote I/O (ioLogik Series). The DI channels monitor the machine status of the chiller, pump, and fan. The DO channels control the settings of the chiller, pump, and fan, based on the information provided by the Ethernet remote I/O (ioLogik E1260), which takes temperature readings around the hypermarket.

Click&Go; Plus also benefits the hypermarket by allowing it to operate its HVAC system according to its business hours. Another key feature of Moxa’s solution is that the I/O and connected serial device’s data, e.g., power meters, can be sent to the MySQL database, displaying the system and energy usage status via the web server. By collecting field site OT data and sending it through Moxa’s data acquisition suite (MX-AOPC Suite) to the database reduces system integrators’ workload immensely. What’s more, it allows the customer to connect its legacy HVAC OT systems to IIoT networks.

The hypermarket’s management can log into a web console that allows them to monitor the entire HVAC system and the amount of energy that has been saved. As the HVAC system can now be remotely monitored, engineers do not need to be dispatched for routine inspections. They are only sent out when a problem arises, which needs immediate attention. Both of these features help the end user to reduce total cost of ownership of the system.

Why Moxa

• Easy to use Click&Go; Plus, a programming-free control logic to control the HVAC system based on current environmental conditions.

• Expansion capability by supporting various interfaces and protocols in one device (e.g., DI/DO, AI/AO, RS-485, Ethernet).

• Saves implementation as well as labour costs with daisy-chain topology.

• Supports active tags to send I/O and RS-485 meter data to the MX-AOPC UA server for HMI integration.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved