First of a kind integration for Umgeni Water.

Umgeni Water is a purifier and distributor of potable water to the greater Durban Metropolitan and surrounding municipalities. The waterworks facility at Durban Heights was frequently unable to supply sufficient water at peak times to metropolitan areas far north of Durban, a problem caused by the increased development north of the city centre and a decades-old distribution infrastructure.

In order to rectify the situation, the company embarked on a project to build a new, one of a kind, pump station at the Durban Heights reservoir that, instead of using the normal gravity feed system, would be able to boost the water feed through the existing distribution network.

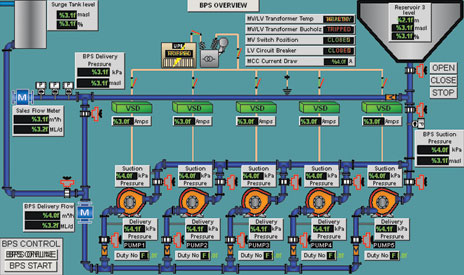

The solution was recommended and engineered by a group of consultants and other experts and involved the control of five 330 kW pumps on variable speed drives, of which four would be running simultaneously. The identified objective of the project was to ensure that sufficient water supply at a constant pressure was maintained at all times to the farthest distribution points, without negatively affecting existing ageing infrastructure.

“This solution was designed to operate completely automatically with only critical operator functionality to give constant supply quality to the end users,” says Abacus Automation project manager, Nico Erasmus. “We were appointed by the main contractor – the Cato Group – to provide a systems integration programming and design service in May 2009 and the project was fast tracked for completion and handover to the client by December 2009.”

The solution involved different suppliers for the three main control components – the PLC, scada and variable speed drives. “It was extremely challenging to ensure seamless integration of the various components. A profibus network was used to link the Allen-Bradley PLC to the Siemens drives via a third party converter. The scada server was then networked to the PLC and HMI by expanding on the existing Ethernet infrastructure,” explains Erasmus. “The PLC had to marshal the information between the components at high speed and ensure delivery in the desired format.”

As this was a working plant, commissioning had to take place with minimal interruption to the distribution network. “However this was a pilot concept project as it was not possible to FAT the entire solution before implementation. The main challenges for the control solution were the unpredictable variables including often abrupt changes in water demand as municipalities came on and off the distribution network, incoming supply pressure changes and other feeds joining the distribution network,” elaborates Erasmus.

The system had to be able to shut down and restart automatically to handle critical conditions like power failures, low incoming water supply and pipe failures on the distribution side. The control also had to cater for a seamless switch-in of the standby pump in the event of a failure to one of the duty pumps.

The objective of constant water flow to the end user during both peak and off-peak periods was obtained by an intricate blend of algorithms monitoring flow rates and pressures from several sources to provide a constant head in the distribution line at all times.

Erasmus points out that one of the biggest challenges faced was that the instrumentation installation and PLC testing had to be done simultaneously. “This tried the patience of many on site as the work schedule was fine tuned to accommodate all the teams. With hindsight, we should have had higher levels of inter-team communication in place. I believe that you can never have too much communication between parties to ensure that things do not ‘fall through the cracks’. That said, the coming together of many minds and the support of understanding wives has produced a ground breaking solution that is a tribute to all involved in its success.”

Dayabaran Moodley, maintenance engineer electrical & instrumentation at Umgeni Water says: “The performance of the pump station meets the design specifications and the requirements. Abacus is to be commended for the way it took the necessary remedial actions whenever required by the project team.”

For more information contact Nico Erasmus, Abacus Automation, +27 (0)31 702 5767, [email protected], www.abacus-automation.co.za

| Tel: | +27 31 702 5767 |

| Email: | [email protected] |

| www: | www.abacus-automation.co.za |

| Articles: | More information and articles about Abacus Automation |

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

© Technews Publishing (Pty) Ltd | All Rights Reserved